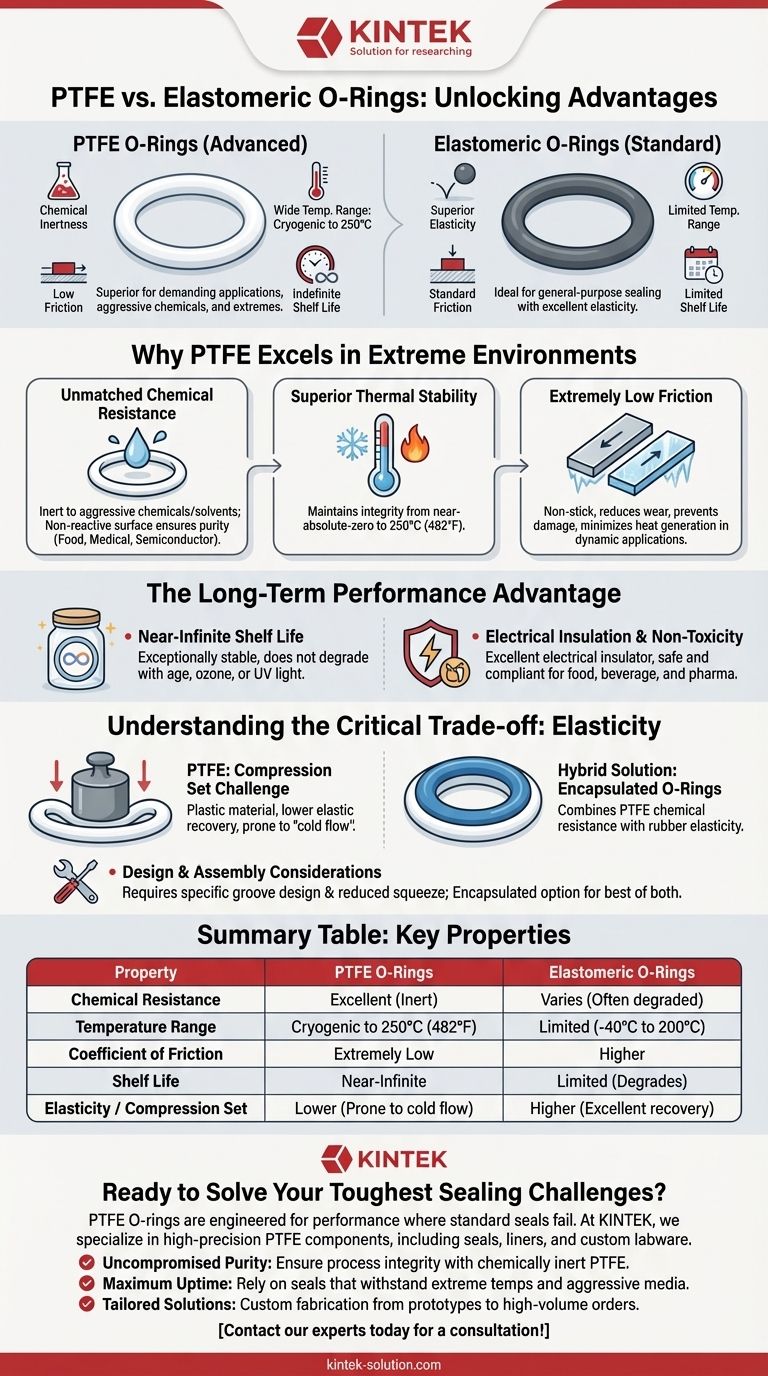

In demanding applications, PTFE O-rings offer significant advantages over traditional elastomeric options. They provide superior chemical inertness, a much wider operational temperature range from cryogenic levels up to 250°C, a remarkably low coefficient of friction, and an almost indefinite shelf life, making them ideal for challenging industrial environments.

While elastomeric (rubber) O-rings provide superior elasticity for general-purpose sealing, PTFE O-rings are the definitive choice for applications involving aggressive chemicals, extreme temperatures, or high-friction dynamic movement where rubber would quickly fail.

Why PTFE Excels in Extreme Environments

The core advantages of Polytetrafluoroethylene (PTFE) stem from its unique molecular structure. This makes it a specialized material for conditions that are too hostile for common elastomers like Nitrile or Viton.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert materials known. This makes it invaluable for sealing aggressive chemicals, solvents, and corrosive fluids that would degrade or dissolve standard rubber O-rings.

Its non-reactive surface ensures the purity of the medium it is sealing, which is critical in food, medical, and semiconductor applications.

Superior Thermal Stability

PTFE O-rings maintain their integrity and sealing capability across an exceptionally wide temperature range, typically from near-absolute-zero up to 250°C (482°F).

In contrast, most elastomers become brittle and crack at very low temperatures or soften and permanently deform at high temperatures, leading to seal failure.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "non-stick" property is a major advantage in dynamic or rotary applications.

This low-friction surface reduces wear on moving parts, prevents damage to pipes and hoses during assembly, and minimizes heat generation in high-speed equipment.

The Long-Term Performance Advantage

Beyond its resistance to harsh conditions, PTFE provides benefits that enhance reliability and reduce long-term costs.

Near-Infinite Shelf Life

Unlike elastomeric O-rings that can degrade over time from exposure to ozone, UV light, or simple aging, PTFE is exceptionally stable. It does not degrade, allowing for an almost infinite shelf life without loss of performance.

Electrical Insulation Properties

PTFE is an excellent electrical insulator. This characteristic makes it a suitable choice for applications where the O-ring must prevent electrical conductivity between sealed components.

Non-Toxicity

The inherent purity and non-toxic nature of PTFE make it a safe and compliant choice for applications in the food processing, beverage, and pharmaceutical industries.

Understanding the Critical Trade-off: Elasticity

While its advantages are significant, it is crucial to understand that PTFE is not a direct replacement for rubber in every situation. The primary trade-off is its lack of "memory."

The Challenge of Compression Set

PTFE is a plastic, not a true elastomer. It does not have the same "bounce-back" or elastic recovery as a rubber O-ring.

Under sustained pressure, PTFE can be subject to "cold flow" or creep, where it slowly deforms and may not return to its original shape. This can compromise sealing performance in applications with fluctuating pressures or frequent assembly/disassembly.

Design and Assembly Considerations

Because of its rigidity, solid PTFE O-rings require different design considerations. Grooves may need to be designed specifically for them, and the amount of cross-sectional "squeeze" is typically reduced compared to a rubber O-ring to facilitate assembly without damage.

The Hybrid Solution: Encapsulated O-Rings

To overcome the elasticity issue, encapsulated O-rings combine the best of both materials. These seals feature an elastomeric core (like Silicone or Viton) inside a seamless PTFE jacket.

This design provides the chemical and temperature resistance of PTFE on the outside while retaining the excellent elasticity and recovery properties of the rubber core.

Making the Right Choice for Your Application

Selecting the correct O-ring material requires a clear understanding of your operational demands.

- If your primary focus is static sealing in a standard environment: A traditional elastomeric O-ring is often more cost-effective and provides better elastic recovery.

- If your primary focus is sealing aggressive chemicals or solvents: Solid PTFE is the superior choice due to its unmatched chemical inertness.

- If your primary focus is a high-temperature or cryogenic application: PTFE's wide operational temperature range makes it far more reliable than most elastomers.

- If your primary focus is a dynamic or rotary seal: PTFE's low-friction surface minimizes wear and heat generation, significantly outperforming rubber.

- If you need both chemical resistance and reliable elastic sealing: An encapsulated O-ring offers a powerful, hybrid solution.

Ultimately, choosing the right O-ring material is a critical engineering decision that directly impacts the reliability and longevity of your assembly.

Summary Table:

| Property | PTFE O-Rings | Elastomeric O-Rings |

|---|---|---|

| Chemical Resistance | Excellent (Inert to most chemicals) | Varies (Often degraded by solvents) |

| Temperature Range | Cryogenic to 250°C (482°F) | Limited (e.g., -40°C to 200°C) |

| Coefficient of Friction | Extremely Low | Higher |

| Shelf Life | Near-Infinite | Limited (Degrades with age/ozone) |

| Elasticity / Compression Set | Lower (Prone to cold flow) | Higher (Excellent recovery) |

Ready to Solve Your Toughest Sealing Challenges?

PTFE O-rings are engineered for performance where standard seals fail. At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and custom labware, for the most demanding industries.

We help customers in the semiconductor, medical, laboratory, and industrial sectors achieve:

- Uncompromised Purity: Ensure the integrity of sensitive processes with our chemically inert PTFE.

- Maximum Uptime: Rely on seals that withstand extreme temperatures and aggressive media.

- Tailored Solutions: From prototypes to high-volume orders, we provide custom fabrication to meet your exact specifications.

Let's engineer the perfect seal for your application. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability