The primary advantage of a PTFE-lined butterfly valve over a lined ball valve in pharmaceutical applications is its inherent cavity-free design. This eliminates dead space where product can accumulate, stagnate, and lead to bacterial growth or cross-contamination between batches. This design superiority directly supports the stringent cleanability and sterilization requirements of the pharmaceutical industry.

While both valve types offer excellent chemical resistance due to their PTFE lining, the choice between them comes down to a fundamental trade-off: The butterfly valve prioritizes a clean, compact design, whereas the ball valve prioritizes an unobstructed flow path.

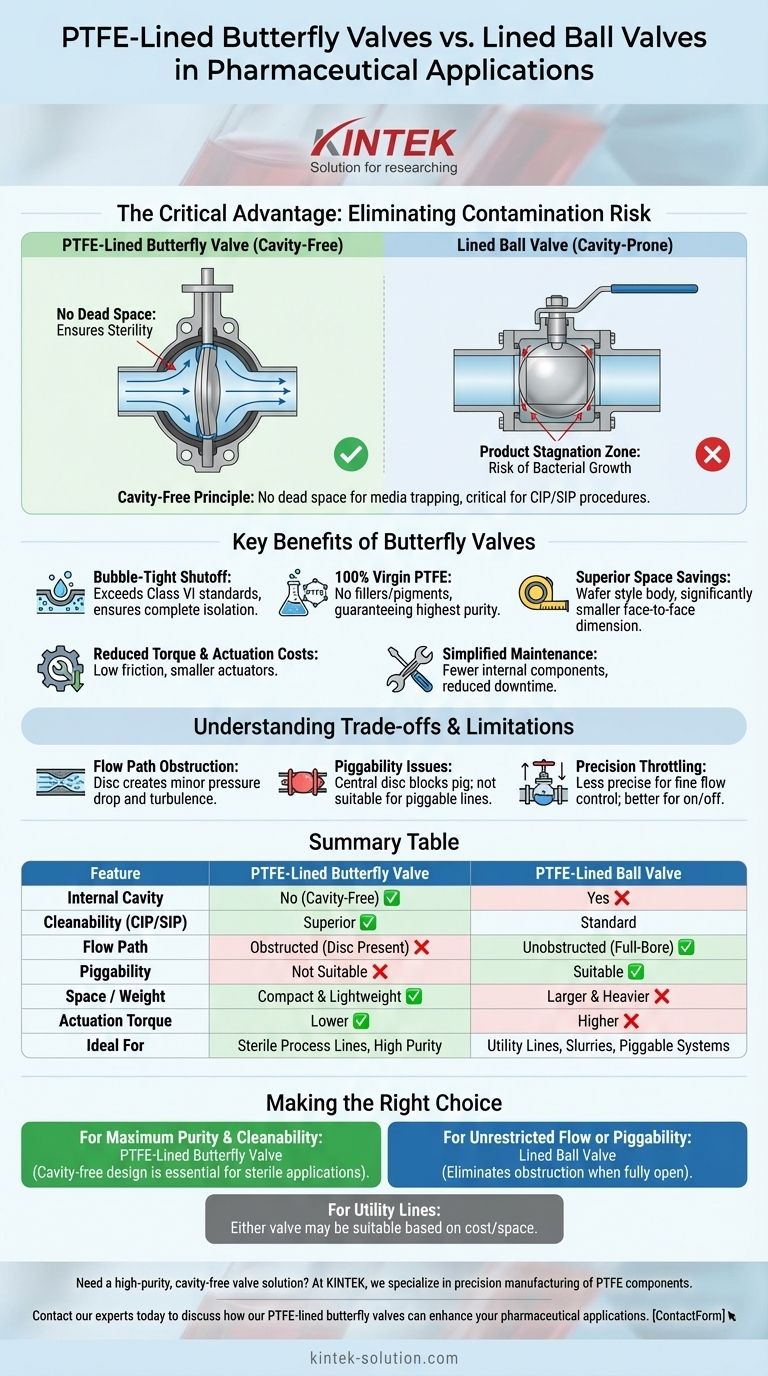

The Critical Advantage: Eliminating Contamination Risk

For any pharmaceutical process, maintaining sterility and preventing batch contamination is the highest priority. The valve's internal geometry is a critical factor in achieving this goal.

The Cavity-Free Principle

A butterfly valve's core strength is its cavity-free design. The disc and seat form a seal directly in the flow path, leaving no dead space for media to become trapped.

This is a critical distinction from lined ball valves, which inherently have a cavity between the ball and the body. Product can stagnate in this void, compromising Clean-in-Place (CIP) and Sterilize-in-Place (SIP) procedures.

Ensuring Bubble-Tight Shutoff

Reliable sealing is essential for isolating process lines and preventing cross-contamination. High-performance PTFE-lined butterfly valves are engineered for bubble-tight shutoff, often exceeding industry standards like Class VI. This ensures complete media isolation when the valve is closed.

Material Integrity with Virgin PTFE

Pharmaceutical applications demand the highest purity materials. These valves utilize a stabilized, fully machined liner made from 100% virgin PTFE. This construction ensures there are no fillers, pigments, or recycled materials that could leach into the process media, guaranteeing product integrity.

Operational and Footprint Efficiency

Beyond process purity, valve selection impacts plant design, automation, and maintenance schedules. The butterfly valve's simple design offers distinct practical advantages.

Superior Space Savings

Butterfly valves have a very thin, "wafer" style body. This results in a significantly smaller face-to-face dimension compared to a lined ball valve, which is crucial for installation in compact piping systems or equipment skids.

Reduced Torque and Actuation Costs

The quarter-turn action of a butterfly valve, combined with the low coefficient of friction of PTFE, results in low operational torque. This allows for the use of smaller, less expensive, and more energy-efficient actuators for automated processes.

Simplified Maintenance

The simple construction of a butterfly valve, with fewer internal components than a ball valve, often translates to easier maintenance and reduced plant downtime. This straightforward design minimizes potential failure points over the valve's service life.

Understanding the Trade-offs and Limitations

No single valve design is perfect for every application. Objectivity requires acknowledging where a butterfly valve may not be the optimal choice.

Flow Path Obstruction

The primary limitation of a butterfly valve is that the disc remains in the center of the flow path even when fully open. This creates a minor obstruction that can cause a pressure drop and flow turbulence.

In contrast, a full-bore lined ball valve provides a completely straight and unobstructed flow path, which is ideal for slurries, viscous fluids, or any process that cannot tolerate flow disturbance.

Piggability

Processes that require "pigging"—sending a device through the pipeline to clean it—cannot use butterfly valves. The central disc completely blocks the pig's path. A full-bore ball valve is required for any piggable line.

Precision Throttling

While butterfly valves can be used for regulating flow, they are generally less precise for fine-throttling applications compared to specialized globe or diaphragm valves. They excel at on/off service and coarse flow control.

Making the Right Choice for Your Pharmaceutical Process

The decision between these two valve types should be driven by the specific demands of the application within your facility.

- If your primary focus is maximum purity and cleanability: The PTFE-lined butterfly valve is the superior choice due to its cavity-free design, which is essential for sterile product-contact applications.

- If your primary focus is an unrestricted flow path or piggability: The lined ball valve is the only viable option, as its design eliminates any obstruction when fully open.

- If your focus is on utility lines (e.g., plant steam, non-critical solvents): Either valve may be suitable, and the decision can be based on secondary factors like cost, space, and weight.

Ultimately, selecting the correct valve is about aligning its fundamental design with the non-negotiable demands of your process.

Summary Table:

| Feature | PTFE-Lined Butterfly Valve | PTFE-Lined Ball Valve |

|---|---|---|

| Internal Cavity | No (Cavity-Free) | Yes |

| Cleanability (CIP/SIP) | Superior | Standard |

| Flow Path | Obstructed (Disc Present) | Unobstructed (Full-Bore) |

| Piggability | Not Suitable | Suitable |

| Space / Weight | Compact & Lightweight | Larger & Heavier |

| Actuation Torque | Lower | Higher |

| Ideal For | Sterile Process Lines, High Purity | Utility Lines, Slurries, Piggable Systems |

Need a high-purity, cavity-free valve solution for your pharmaceutical process?

At KINTEK, we specialize in the precision manufacturing of PTFE components, including seals, liners, and custom labware, for the most demanding industries. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a valve solution perfectly aligned with your stringent sterility and cleanability requirements.

Contact our experts today to discuss how our PTFE-lined butterfly valves can enhance the purity and efficiency of your pharmaceutical applications.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability