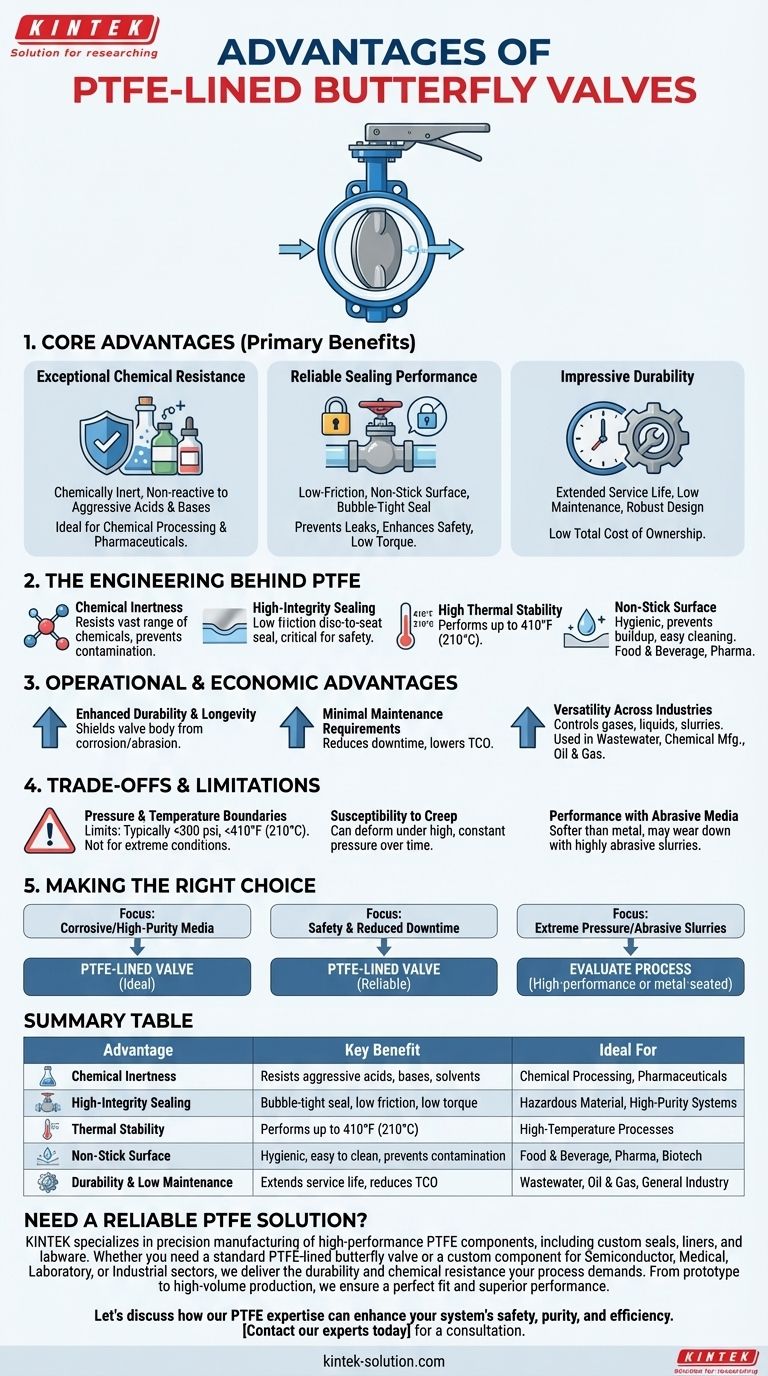

At their core, the primary advantages of PTFE-lined butterfly valves are their exceptional chemical resistance, reliable sealing performance, and impressive durability in harsh industrial environments. These characteristics make them a cost-effective and low-maintenance solution for controlling corrosive or high-purity fluids.

A PTFE lining elevates a standard butterfly valve from a general-purpose component to a specialized tool for demanding applications. It provides a chemically inert, non-stick barrier that protects both the valve and the process media, ensuring safety, purity, and long-term operational reliability.

The Engineering Behind PTFE's Superior Performance

The advantages of a PTFE-lined valve are not arbitrary; they stem directly from the unique molecular properties of Polytetrafluoroethylene (PTFE). Understanding these properties clarifies why this material is a go-to choice in critical industries.

Exceptional Chemical Inertness

PTFE is one of the most non-reactive substances known. Its inert nature means it will not corrode or degrade when exposed to a vast range of aggressive chemicals, acids, and bases.

This makes it an ideal choice for chemical processing and pharmaceutical applications, where it can handle corrosive substances safely without contaminating the product.

High-Integrity Sealing

PTFE has an extremely low coefficient of friction, creating a smooth, non-stick surface. This allows the valve's disc to close tightly against the PTFE seat, forming a bubble-tight seal.

This superior sealing capability is critical for safety, preventing the leakage of hazardous materials and ensuring process integrity. The low friction also reduces the torque required to operate the valve, minimizing wear on actuation components.

High Thermal Stability

PTFE-lined valves maintain their structural integrity and performance characteristics across a wide range of temperatures.

They are typically rated for service conditions up to 410°F (210°C), making them suitable for many high-temperature industrial processes where other elastomers would fail.

Non-Stick and Hygienic Surface

The non-stick quality of PTFE prevents process media from accumulating on the valve's internal surfaces.

This is a crucial advantage in the food and beverage and pharmaceutical industries, as it reduces the risk of contamination, simplifies cleaning, and helps maintain a hygienic process line.

Operational and Economic Advantages

Beyond its material properties, choosing a PTFE-lined butterfly valve translates into tangible benefits for operations, maintenance, and the bottom line.

Enhanced Durability and Longevity

By shielding the valve body from corrosive and abrasive media, the PTFE liner significantly extends the component's service life.

The material's inherent toughness and low-friction nature reduce wear and tear, leading to a more durable and reliable valve that withstands the rigors of industrial use.

Minimal Maintenance Requirements

The combination of durability and a non-stick surface means these valves require very little maintenance. The robust design prevents common failure modes like corrosion and material buildup.

This reduces process downtime and lowers the total cost of ownership over the valve's lifespan.

Versatility Across Industries

PTFE-lined butterfly valves are not limited to a single function. They are used to control gases, liquids, and even some slurries.

Their adaptability makes them a standard component in diverse sectors, including wastewater treatment, chemical manufacturing, and the oil and gas industry.

Understanding the Trade-offs and Limitations

While highly effective, PTFE-lined valves are not a universal solution. Being aware of their operational boundaries is key to successful implementation.

Pressure and Temperature Boundaries

PTFE has clear operational limits. Most designs are intended for applications below 300 psi and the previously mentioned 410°F (210°C).

For processes involving extreme pressures or temperatures beyond these limits, a high-performance or metal-seated butterfly valve is a more appropriate choice.

Susceptibility to Creep

PTFE is a type of thermoplastic that can be susceptible to "creep," or cold flow. Under high, constant pressure, the material can slowly deform over time.

This can eventually compromise the seal in high-pressure applications. Proper valve selection and design are critical to mitigate this risk.

Performance with Abrasive Media

While PTFE is durable, it is softer than metal. In applications with highly abrasive slurries, the liner can eventually wear down, potentially leading to failure.

For these specific cases, a valve with a more abrasion-resistant liner or a different valve type may be necessary.

Making the Right Choice for Your Application

Selecting the correct valve requires aligning its capabilities with your primary operational goal.

- If your primary focus is handling corrosive chemicals or high-purity media: The unmatched chemical inertness and non-contaminating surface of a PTFE-lined valve make it the ideal choice.

- If your primary focus is operational safety and reducing downtime: The valve's superior sealing capabilities and low-maintenance design provide long-term reliability and protect against hazardous leaks.

- If your primary focus is managing extreme high pressures or abrasive slurries: You should carefully evaluate the process conditions, as a more specialized high-performance or metal-seated valve may offer better longevity.

Ultimately, a well-chosen PTFE-lined butterfly valve is a powerful tool for ensuring safe, pure, and efficient fluid control in demanding industrial systems.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Chemical Inertness | Resists a vast range of aggressive acids, bases, and solvents. | Chemical Processing, Pharmaceuticals |

| High-Integrity Sealing | Bubble-tight seal with low friction for safety and low torque. | Hazardous Material Handling, High-Purity Systems |

| Thermal Stability | Maintains performance up to 410°F (210°C). | High-Temperature Processes |

| Non-Stick Surface | Hygienic, easy to clean, prevents contamination. | Food & Beverage, Pharmaceutical, Biotechnology |

| Durability & Low Maintenance | Extends service life and reduces total cost of ownership. | Wastewater Treatment, Oil & Gas, General Industry |

Need a reliable PTFE component solution for your demanding application?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including custom seals, liners, and labware. Whether you require a standard PTFE-lined butterfly valve or a custom-fabricated component for the semiconductor, medical, laboratory, or industrial sectors, we deliver the durability and chemical resistance your process demands.

We partner with you from prototype to high-volume production, ensuring a perfect fit and superior performance. Let's discuss how our PTFE expertise can enhance your system's safety, purity, and efficiency.

Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials