In RF applications, the primary advantages of PTFE laminates are their exceptionally low dielectric constant and low signal loss, which directly translate to superior signal integrity and efficiency at high frequencies. Combined with their outstanding thermal and chemical stability, these properties make PTFE the material of choice for demanding RF and microwave circuits.

The core challenge in high-frequency design is that the circuit board material ceases to be a passive component and actively influences the signal. PTFE laminates excel because their unique electrical properties minimize this unwanted influence, preserving the purity and power of the signal from source to destination.

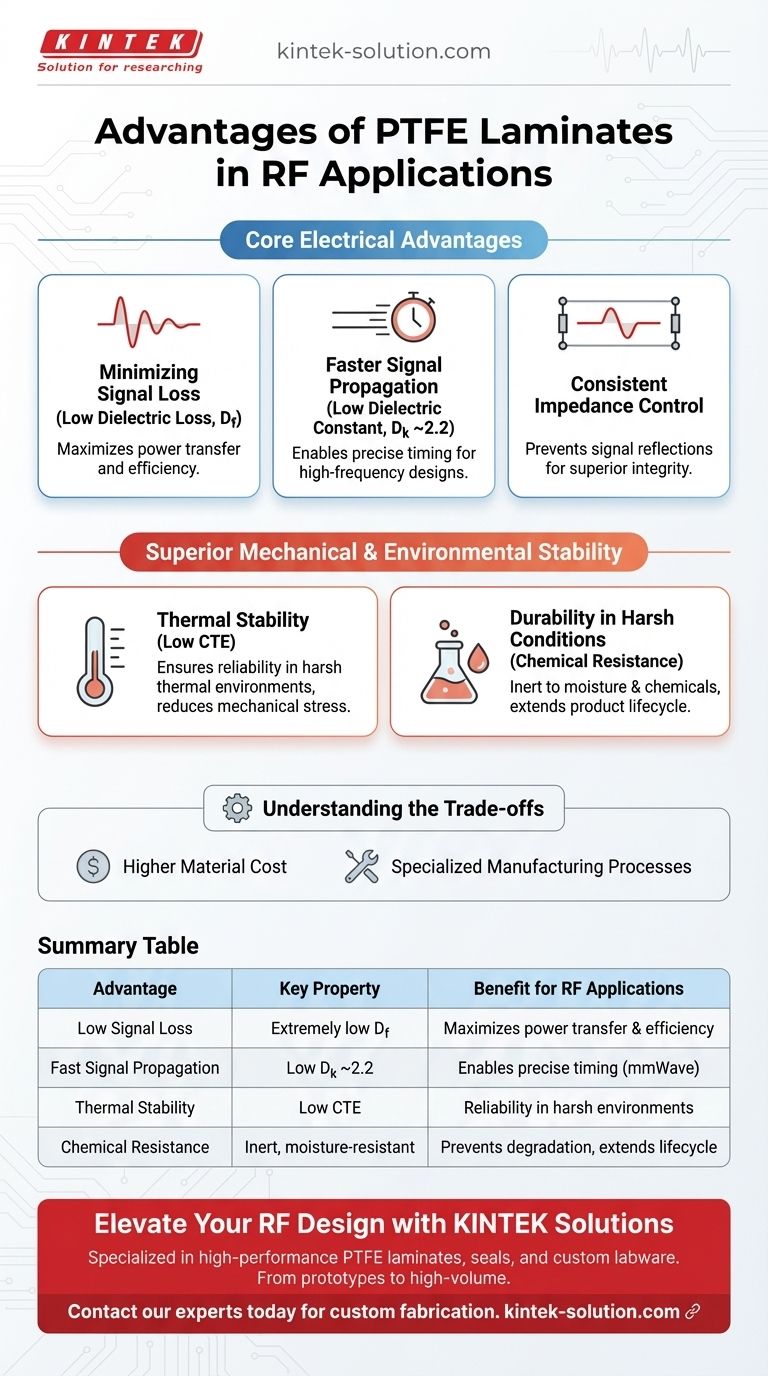

The Core Electrical Advantages of PTFE

At radio frequencies, the substrate material your components are mounted on is as critical as the components themselves. PTFE's properties are uniquely suited to manage the physics of high-frequency signal transmission.

Minimizing Signal Loss (Low Dielectric Loss)

Every substrate material absorbs a small amount of the electrical energy passing through it, converting it into heat. This is known as dielectric loss, quantified by the dissipation factor (Df) or loss tangent.

PTFE has an extremely low dissipation factor. This means a significantly smaller portion of your RF signal is wasted as heat, ensuring maximum power reaches its intended destination. This is critical in applications like high-power amplifiers or sensitive receivers.

Enabling Faster Signal Propagation (Low Dielectric Constant)

The dielectric constant (Dk) of a material determines how fast an electrical signal travels through it. The lower the Dk, the faster the signal propagation.

PTFE laminates can have a Dk as low as 2.2, which is very close to a vacuum (1.0) and far superior to standard materials like FR-4 (which is typically ~4.5). This higher speed is essential for high-frequency designs where timing is critical.

Ensuring Consistent Impedance Control

Stable impedance is vital for preventing signal reflections and maintaining signal integrity. The low and stable Dk of PTFE across a wide range of frequencies makes it easier to design and manufacture transmission lines with precise, predictable impedance.

Superior Mechanical and Environmental Stability

RF devices are often deployed in environments with significant temperature fluctuations or exposure to chemicals. PTFE's inherent stability ensures the circuit remains reliable over its entire operational life.

Performance Under Temperature Swings (Low CTE)

PTFE has a low Coefficient of Thermal Expansion (CTE). This means it expands and contracts very little with changes in temperature.

This stability is crucial because it minimizes mechanical stress on copper traces, component solder joints, and plated through-holes (vias). This drastically reduces the risk of intermittent connections or outright circuit failure in automotive, aerospace, or outdoor applications.

Durability in Harsh Conditions (High Chemical Resistance)

As an inert material, PTFE is highly resistant to moisture, solvents, and other chemicals. This property ensures that the laminate's electrical characteristics do not degrade over time due to environmental exposure, leading to a longer and more reliable product lifecycle.

Understanding the Trade-offs

While PTFE offers premier performance, it is not the default choice for every application. Acknowledging the trade-offs is key to making an informed engineering decision.

Higher Material Cost

PTFE laminates are significantly more expensive than conventional PCB materials like FR-4. This cost is a direct result of the complex manufacturing process and the premium raw materials used.

Specialized Manufacturing Processes

Fabricating PCBs with PTFE-based laminates requires specialized equipment and expertise. The material's unique properties can make processes like drilling and plating more challenging and costly than with standard substrates.

Making the Right Choice for Your Application

Selecting your RF laminate is a balance between performance requirements, environmental resilience, and budget.

- If your primary focus is elite high-frequency performance (e.g., mmWave, satellite communication, or high-speed data): PTFE's low loss and low dielectric constant are essential and often non-negotiable.

- If your primary focus is reliability in harsh thermal environments (e.g., automotive radar or aerospace systems): PTFE's thermal stability and low CTE provide the mechanical robustness needed to prevent failures.

- If your primary focus is cost-sensitive designs operating at lower frequencies (e.g., below 1-2 GHz): A higher-loss material like FR-4 may provide adequate performance for a fraction of the cost.

Ultimately, choosing a PTFE laminate is an investment in unparalleled electrical performance and long-term reliability for your most critical RF applications.

Summary Table:

| Advantage | Key Property | Benefit for RF Applications |

|---|---|---|

| Low Signal Loss | Extremely low dissipation factor (Df) | Maximizes power transfer and efficiency in high-frequency signals |

| Fast Signal Propagation | Low dielectric constant (Dk ~2.2) | Enables precise timing for high-speed and mmWave designs |

| Thermal Stability | Low coefficient of thermal expansion (CTE) | Ensures reliability in automotive, aerospace, and harsh environments |

| Chemical Resistance | Inert, moisture-resistant material | Prevents degradation and extends product lifecycle |

Ready to elevate your RF design with precision-engineered PTFE components?

At KINTEK, we specialize in manufacturing high-performance PTFE laminates, seals, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your RF applications achieve optimal signal integrity and long-term reliability.

Contact our experts today to discuss how our PTFE solutions can meet your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Microwave Digestion Vessels for Demanding Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments