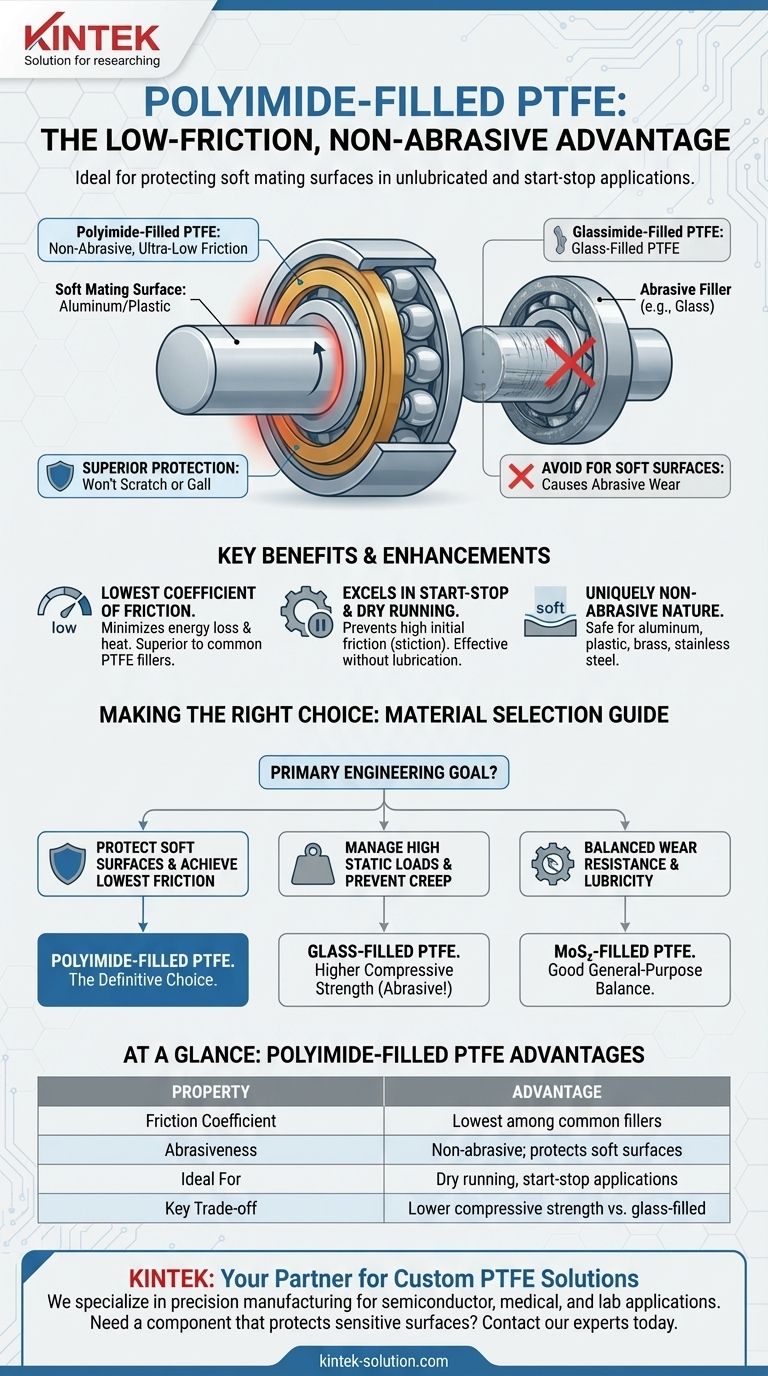

At its core, polyimide-filled Polytetrafluoroethylene (PTFE) offers a unique combination of extremely low friction and a non-abrasive nature. This makes it the superior choice for applications involving soft mating surfaces like aluminum or plastics, particularly in conditions that are unlubricated (dry running) or involve frequent starting and stopping.

The primary advantage of adding polyimide to PTFE is creating a material with the lowest coefficient of friction among common fillers, which excels at protecting soft or sensitive mating surfaces from wear.

The Foundation: Understanding PTFE's Core Strengths

Before examining the role of the polyimide filler, it's essential to understand the inherent properties of the base PTFE material. These characteristics make it a versatile engineering plastic for demanding environments.

Exceptional Chemical and Thermal Resistance

PTFE is famously inert and resistant to nearly all industrial chemicals and solvents. It also maintains its properties over an extremely wide temperature range, from -325°F to +500°F (-200°C to +260°C).

Innately Low Coefficient of Friction

Virgin PTFE has one of the lowest friction coefficients of any solid material, often compared to wet ice on wet ice. This "non-stick" quality is fundamental to its use in seals and bearings.

Durability and Versatility

The material does not embrittle or age from weather or UV exposure. It's also non-toxic and can be FDA-approved, making it safe for a wide range of applications.

How Polyimide Enhances PTFE

While virgin PTFE is excellent, it has limitations, such as poor wear resistance and deformation under load (creep). Fillers are added to improve these mechanical properties. Polyimide is a specialized filler that provides a distinct set of enhancements.

Achieving the Lowest Friction

Of all the common PTFE fillers, polyimide provides the lowest coefficient of friction. This minimizes energy loss and heat generation in moving parts, maximizing operational efficiency.

A Uniquely Non-Abrasive Nature

Unlike harder fillers such as glass, polyimide is non-abrasive. This is its most critical advantage when designing components that will interact with softer, more sensitive materials.

Ideal for Soft Mating Surfaces

Because it is non-abrasive, polyimide-filled PTFE is the perfect choice for dynamic applications involving shafts or surfaces made of aluminum, plastic, brass, or stainless steel. It will not scratch or gall these softer materials.

Superior Performance in Demanding Conditions

This blend performs exceptionally well in dry running or non-lubricated systems. It is also highly effective in start-stop applications, where the initial friction (stiction) can cause significant wear with other materials.

Understanding the Trade-offs and Alternatives

Choosing polyimide-filled PTFE means prioritizing low friction and surface protection. In other scenarios, different fillers may be more appropriate.

When to Consider Glass-Filled PTFE

If your primary concern is high compressive strength and resistance to creep (deformation under load), glass-filled PTFE is a better choice. The glass fibers significantly improve mechanical robustness, but they are abrasive and not suitable for soft shafts.

When to Consider MoS₂-Filled PTFE

Molybdenum disulfide (MoS₂) acts as a dry lubricant. It is added to increase surface hardness and wear resistance without a major penalty to friction. It is often used in combination with other fillers for a balanced performance profile.

The Limitation of Polyimide Filler

The primary trade-off is mechanical strength. While polyimide improves wear resistance over virgin PTFE, it does not provide the same level of compressive strength or creep resistance as harder fillers like glass. It is not the ideal choice for very high-load applications.

Making the Right Choice for Your Application

Selecting the correct material blend is critical for the performance and longevity of your component. Your primary engineering goal should guide your decision.

- If your primary focus is protecting a soft mating surface (like aluminum or plastic) and achieving the lowest possible friction: Polyimide-filled PTFE is the definitive choice.

- If your primary focus is managing high static loads and preventing material creep in a high-pressure seal: Glass-filled PTFE is the more suitable option, provided the mating surface is hard enough to resist abrasion.

- If your primary focus is a general-purpose improvement in wear resistance and hardness with good lubricity: MoS₂-filled PTFE offers a balanced set of properties.

By understanding these key distinctions, you can select the precise material engineered to succeed in your specific application.

Summary Table:

| Property | Advantage of Polyimide-Filled PTFE |

|---|---|

| Friction Coefficient | Lowest among common PTFE fillers |

| Abrasiveness | Non-abrasive; protects soft surfaces like aluminum & plastic |

| Ideal For | Dry running, frequent start-stop applications |

| Key Trade-off | Lower compressive strength vs. glass-filled PTFE |

Need a custom PTFE component that protects your sensitive mating surfaces?

KINTEK specializes in precision manufacturing of PTFE components, including polyimide-filled seals, liners, and labware. We understand the critical balance of low friction and non-abrasive performance required for semiconductor, medical, and laboratory applications.

Our custom fabrication services, from prototypes to high-volume orders, ensure you get the exact material solution for your application's unique demands.

Contact our experts today to discuss how we can enhance your design with the right PTFE material.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications