The primary advantages of PTFE washers are their exceptional resistance to chemicals, their stability across extreme temperatures, and their extremely low coefficient offriction. These properties make Polytetrafluoroethylene (PTFE) the material of choice for demanding applications where conventional materials would quickly fail.

PTFE is not a general-purpose washer; it is a high-performance sealing and insulation solution. Its value is most apparent in environments characterized by corrosive chemicals, extreme temperatures, or the need for non-stick, low-friction surfaces.

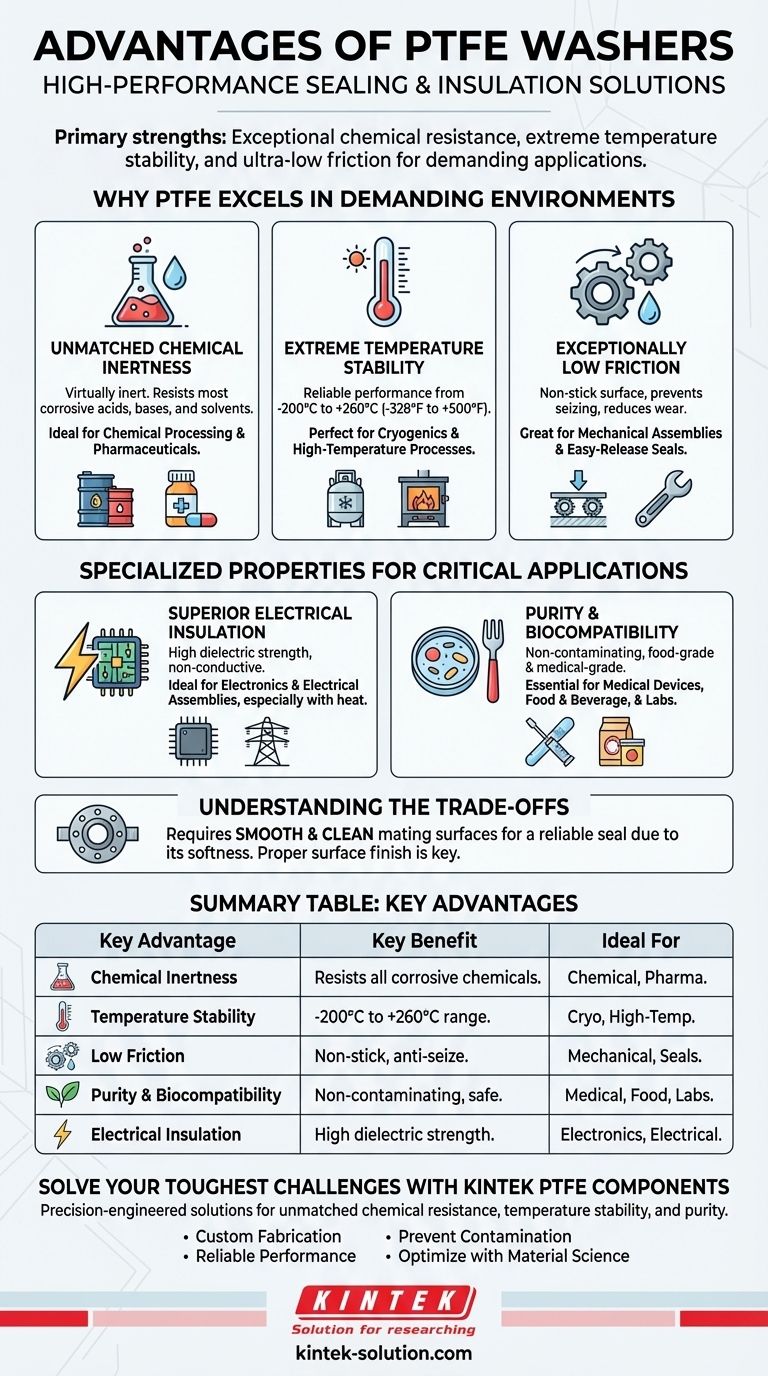

Why PTFE Excels in Demanding Environments

The unique molecular structure of PTFE gives it a combination of properties that are unmatched by most other polymers or metals. This makes it an essential component in specialized industrial, electronic, and scientific applications.

Unmatched Chemical Inertness

PTFE is one of the most chemically resistant materials known. It is virtually inert and does not react with most corrosive acids, bases, or solvents.

This property is critical in industries like chemical processing and pharmaceuticals, where components are constantly exposed to aggressive substances that would degrade lesser materials.

Extreme Temperature Stability

PTFE washers perform reliably across an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This allows them to be used in cryogenic applications as well as high-temperature processes where materials like rubber or other plastics would become brittle or melt.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This creates a "non-stick" surface.

In mechanical assemblies, this reduces wear and prevents parts from seizing. In sealing applications, it ensures the washer does not adhere to mating surfaces, allowing for easier disassembly and maintenance.

Specialized Properties for Critical Applications

Beyond its core strengths, PTFE offers further advantages that make it indispensable for specific, highly regulated industries.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with high dielectric strength. It does not conduct electricity, making it ideal for isolating components in electronic and electrical assemblies.

Its ability to also withstand high temperatures makes it particularly valuable for electronics that generate significant heat during operation.

Purity and Biocompatibility

PTFE is inherently non-contaminating and can be manufactured to food-grade and medical-grade standards. It is biocompatible, meaning it does not react with bodily tissues or fluids.

This purity makes PTFE washers essential in food and beverage processing, medical devices, and laboratory equipment where preventing contamination is a primary concern.

Understanding the Trade-offs

While highly capable, PTFE is not the solution for every problem. Understanding its primary limitation is key to using it effectively.

The Need for Surface Preparation

PTFE is a relatively soft material. To achieve a reliable, leak-proof seal, PTFE washers require smooth and clean flange or mating surfaces.

Rough or irregular surfaces can create leak paths. In such cases, using a thicker, more malleable PTFE washer can sometimes help it conform to minor imperfections, but proper surface finishing is the most reliable solution. Its primary role is often sealing and insulating, not providing high compressive strength like a steel washer.

Making the Right Choice for Your Application

To determine if PTFE is the correct material, evaluate its strengths against the primary demands of your project.

- If your primary focus is resisting aggressive chemicals: PTFE is an industry-leading choice, capable of handling substances that corrode most metals and plastics.

- If your primary focus is performance at extreme temperatures: PTFE's vast operating range makes it one of the few viable options for both cryogenic and high-heat applications.

- If your primary focus is reducing friction or creating a non-stick surface: PTFE's exceptionally low coefficient of friction is ideal for moving parts and easy-release seals.

- If your primary focus is electrical insulation: PTFE provides excellent dielectric properties, especially in applications that also involve high heat.

By understanding its unique capabilities, you can confidently deploy PTFE as a powerful problem-solver for your most challenging applications.

Summary Table:

| Key Advantage | Key Benefit | Ideal For |

|---|---|---|

| Chemical Inertness | Resists virtually all corrosive acids, bases, and solvents. | Chemical Processing, Pharmaceuticals |

| Temperature Stability | Performs reliably from -200°C to +260°C (-328°F to +500°F). | Cryogenics, High-Temperature Processes |

| Low Friction | Non-stick surface prevents seizing and reduces wear. | Mechanical Assemblies, Easy-Release Seals |

| Purity & Biocompatibility | Non-contaminating, meets food-grade and medical-grade standards. | Medical Devices, Food & Beverage, Laboratories |

| Electrical Insulation | Excellent dielectric strength, even at high temperatures. | Electronics, Electrical Assemblies |

Solve Your Toughest Sealing Challenges with KINTEK PTFE Components

Do your applications demand unmatched chemical resistance, extreme temperature stability, or absolute purity? The unique properties of PTFE make it the ideal solution for the most demanding environments in the semiconductor, medical, laboratory, and industrial sectors.

At KINTEK, we don't just supply standard parts; we provide precision-engineered solutions. We specialize in the custom fabrication of high-performance PTFE components—including seals, liners, and labware—from initial prototypes to high-volume production runs.

Partner with KINTEK to:

- Ensure Reliability: Get components built to perform consistently under extreme conditions.

- Prevent Contamination: Utilize our medically pure PTFE for critical applications.

- Optimize Performance: Benefit from our expertise in material science and precision production.

Let's discuss your specific requirements. Contact our engineering team today for a consultation and see how our custom PTFE solutions can enhance your product's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments