In short, bronze-filled PTFE bushes offer a significant upgrade in mechanical performance over standard PTFE. By blending bronze powder (up to 60%) into the PTFE matrix, the resulting material gains superior compressive strength, enhanced wear resistance, and dramatically improved thermal conductivity. This makes it an ideal choice for demanding, high-load, and high-speed applications where unfilled PTFE would deform or fail.

While standard PTFE is prized for its extreme low friction and chemical inertness, it is mechanically soft. Adding a bronze filler transforms it from a simple non-stick material into a robust, load-bearing engineering component capable of withstanding significant mechanical stress.

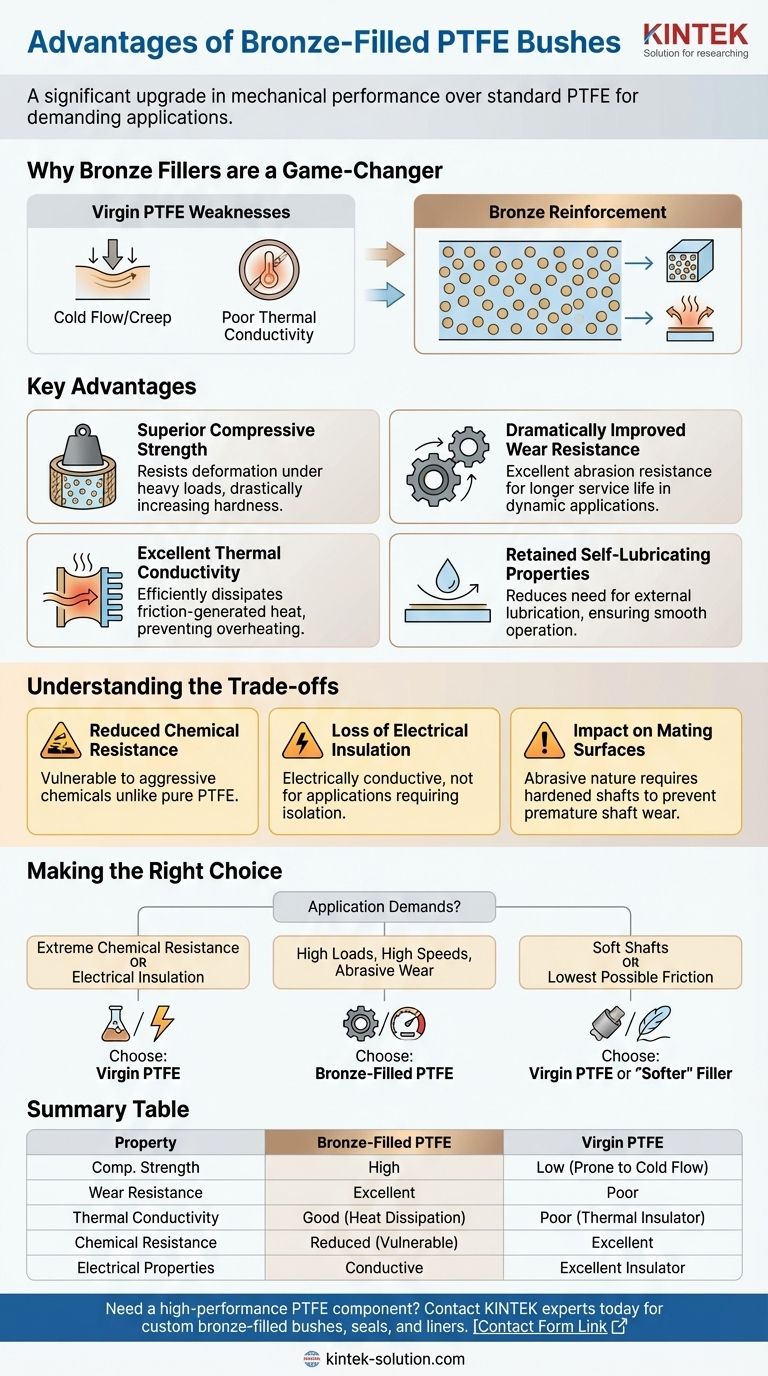

Why Bronze Fillers are a Game-Changer

To understand the advantages of bronze-filled PTFE, it's essential to first recognize the limitations of the base material.

The Weakness of Unfilled (Virgin) PTFE

Unfilled PTFE is exceptionally slick and resistant to chemicals, but it is also soft. Under significant pressure, it is prone to "cold flow" or creep, meaning it will slowly deform and lose its shape, even at room temperature.

Furthermore, pure PTFE is an excellent thermal insulator. In moving applications, friction generates heat that gets trapped, which can cause the bushing to soften and fail prematurely.

How Bronze Reinforces the PTFE Matrix

Introducing fine bronze particles into the PTFE creates a composite material that overcomes these weaknesses. The bronze acts as a reinforcing agent, fundamentally changing the material's properties.

Key Advantages of Bronze-Filled PTFE

The addition of bronze delivers three primary performance enhancements that are critical for mechanical applications.

Superior Compressive Strength

The bronze particles provide a strong internal structure, drastically increasing the material's hardness and its ability to resist deformation under heavy loads. This makes bronze-filled bushes suitable for high-pressure systems where virgin PTFE would be crushed.

Dramatically Improved Wear Resistance

This is one of the most significant benefits. The hardness of the bronze filler gives the bushing excellent resistance to abrasion and wear from continuous motion, leading to a much longer service life in dynamic applications like bearings and piston rings.

Excellent Thermal Conductivity

Unlike pure PTFE, bronze is an excellent thermal conductor. It effectively pulls friction-generated heat away from the sliding surface and dissipates it into the housing. This prevents overheating, maintains material integrity at higher speeds, and expands the operational temperature range.

Retained Self-Lubricating Properties

While adding a filler, the material retains the inherent low-friction, self-lubricating nature of PTFE. This reduces the need for external lubrication, minimizing maintenance and ensuring smooth, efficient operation.

Understanding the Trade-offs

Adding bronze is not a universal upgrade; it involves clear engineering trade-offs that are critical to understand for proper material selection.

Reduced Chemical Resistance

The primary compromise is a loss of chemical inertness. Bronze is not nearly as resistant to corrosive chemicals as pure PTFE. In aggressive chemical environments, the bronze filler can be attacked, compromising the bushing's integrity.

Loss of Electrical Insulation

PTFE is an exceptional electrical insulator. Bronze is a conductor. Consequently, bronze-filled PTFE is electrically conductive and must not be used in applications requiring electrical isolation.

Impact on Mating Surfaces

The increased hardness and abrasive nature of the bronze filler mean it is best paired with hardened shafts. Using a bronze-filled bush against a soft shaft material can result in premature wear of the shaft itself.

Making the Right Choice for Your Application

Choosing between virgin PTFE and bronze-filled PTFE depends entirely on the specific demands of your operating environment.

- If your primary focus is extreme chemical resistance or electrical insulation: Virgin PTFE is the correct and necessary choice.

- If your primary focus is handling high mechanical loads, high speeds, or abrasive wear: Bronze-filled PTFE is the definitive upgrade for performance and longevity.

- If you are working with soft shafts or require the absolute lowest possible friction: Virgin PTFE or a PTFE with a "softer" filler may be more appropriate.

Ultimately, selecting the correct material is fundamental to ensuring the reliability and performance of your design.

Summary Table:

| Property | Bronze-Filled PTFE | Virgin PTFE |

|---|---|---|

| Compressive Strength | High | Low (Prone to Cold Flow) |

| Wear Resistance | Excellent | Poor |

| Thermal Conductivity | Good (Heat Dissipation) | Poor (Thermal Insulator) |

| Chemical Resistance | Reduced (Bronze is vulnerable) | Excellent |

| Electrical Properties | Conductive | Excellent Insulator |

Need a high-performance PTFE component for your demanding application?

At KINTEK, we specialize in precision manufacturing of PTFE components, including custom bronze-filled bushes, seals, and liners. We understand the critical balance between mechanical strength, wear resistance, and environmental compatibility required in the semiconductor, medical, laboratory, and industrial sectors.

Whether you need a prototype or a high-volume order, our expertise ensures you get the right material and design for superior performance and longevity.

Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance