In the chemical processing industry, PTFE gaskets are the primary solution for sealing critical connection points that handle aggressive and corrosive media. They are most commonly found sealing pipe flanges, valves, pumps, and process vessels like heat exchangers and distillation towers, where their chemical inertness is essential for preventing leaks and ensuring process integrity.

The core value of a PTFE gasket is not just its application, but its function as a fail-safe barrier. Its near-total immunity to chemical attack makes it the default choice for containing hazardous substances, protecting high-value equipment, and maintaining product purity in the most demanding environments.

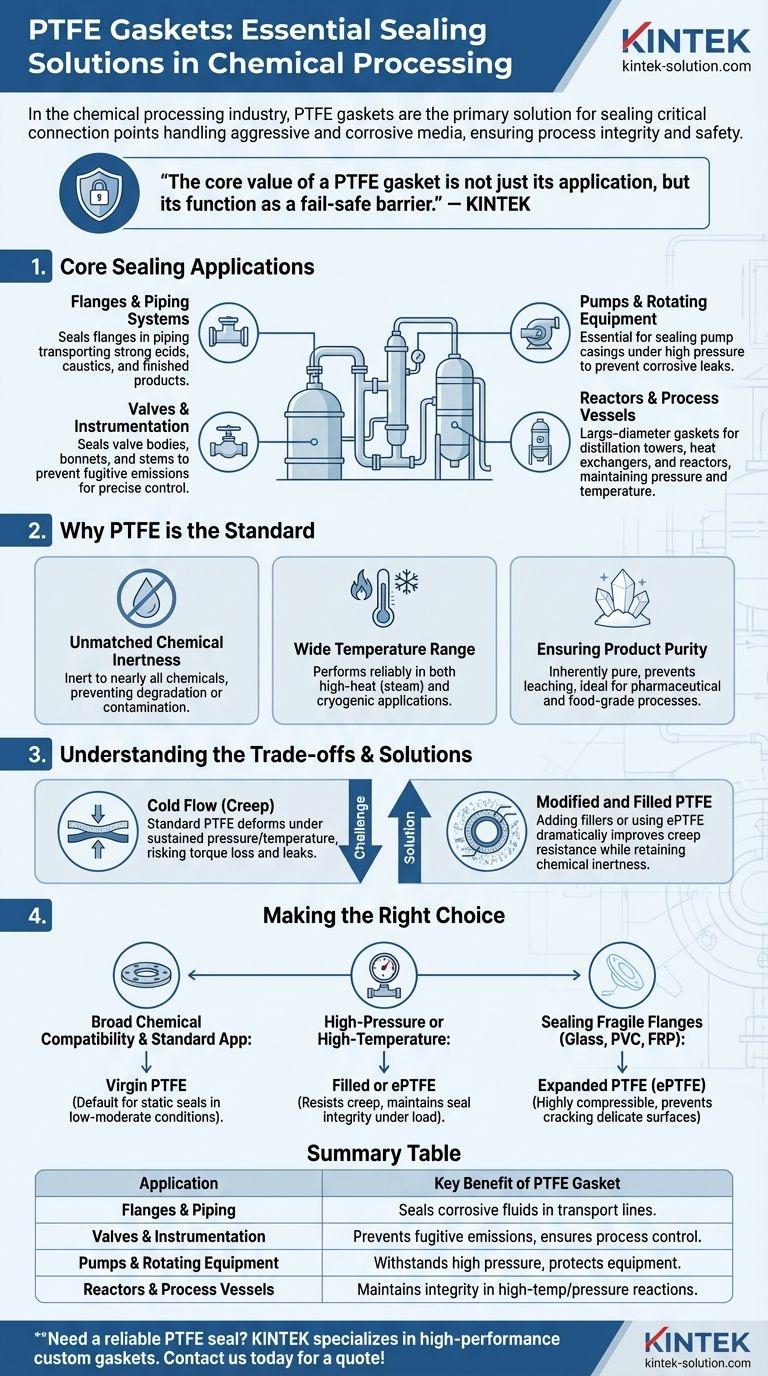

Core Sealing Applications in Chemical Processing

PTFE's unique properties make it indispensable for sealing the most vulnerable points in a chemical process stream. Its application is directly tied to preventing the escape of corrosive, toxic, or high-purity fluids.

Flanges and Piping Systems

Gaskets are placed between the faces of two connecting pipe flanges to create a static seal. In chemical plants, these pipes transport everything from raw materials like strong acids and caustic chemicals to finished products and steam. PTFE ensures a durable, non-degrading seal.

Valves and Instrumentation

Valves are critical for controlling the flow of process fluids. PTFE gaskets and packings are used to seal valve bodies, bonnets, and stems, preventing fugitive emissions that are both hazardous and costly. This ensures precise process control and environmental compliance.

Pumps and Rotating Equipment

Pumps are used to move aggressive chemicals, often under high pressure. PTFE gaskets are essential for sealing pump casings and connection flanges, preventing leaks of corrosive liquids that could damage the pump itself and surrounding equipment.

Reactors and Process Vessels

Large-scale equipment such as distillation towers, heat exchangers, kettles, and glass-lined reactors rely on large-diameter PTFE gaskets. These seals are critical for maintaining the internal pressure and temperature required for chemical reactions while resisting the vessel's contents.

Why PTFE is the Standard for Corrosive Environments

The widespread use of PTFE is not accidental; it is a direct result of material properties that perfectly match the challenges of the chemical industry.

Unmatched Chemical Inertness

The defining feature of PTFE is its non-reactivity. It is inert to nearly all industrial chemicals, including the most aggressive acids, solvents, hydrocarbons, and caustics. This means the gasket itself will not degrade, swell, or contaminate the process media.

Wide Temperature Range

Chemical processes often involve extreme temperatures. PTFE gaskets perform reliably in both high-heat applications, such as steam pipes, and in cryogenic services, providing a versatile sealing solution across a vast operational window.

Ensuring Product Purity

In applications like pharmaceutical or food-grade chemical manufacturing, preventing contamination is paramount. PTFE is an inherently pure material that does not leach chemicals into the process stream, protecting the integrity and quality of the final product.

Understanding the Trade-offs and Limitations

While incredibly capable, standard PTFE is not without its challenges. Understanding its limitations is key to using it correctly and safely.

The Challenge of Cold Flow (Creep)

Standard, or "virgin," PTFE has a tendency to deform or "creep" over time when subjected to sustained pressure and temperature. This can cause the bolts on a flange to lose their torque, potentially leading to a leak.

The Solution: Modified and Filled PTFE

This limitation is overcome by using modified or filled PTFE. By adding fillers like glass fiber, carbon, or silica, or by expanding the material into a soft, highly conformable structure (ePTFE), engineers dramatically improve the gasket's resistance to creep while often retaining its excellent chemical resistance.

Making the Right Choice for Your Application

Selecting the correct type of PTFE gasket is critical for ensuring a long-lasting, leak-free seal.

- If your primary focus is broad chemical compatibility in a standard application: Virgin PTFE is the default choice for static seals on flat flanges in low-to-moderate pressure and temperature systems.

- If your primary focus is high-pressure or high-temperature service: A filled PTFE (e.g., glass-filled) or a structured ePTFE gasket is necessary to resist creep and maintain seal integrity under load.

- If your primary focus is sealing fragile flanges (e.g., glass, PVC, or FRP): A highly compressible, soft gasket like expanded PTFE (ePTFE) is essential to create a tight seal without cracking or damaging the delicate flange surfaces.

Ultimately, matching the specific demands of your chemical process to the right type of PTFE gasket is the key to safe, reliable, and efficient operations.

Summary Table:

| Application | Key Benefit of PTFE Gasket |

|---|---|

| Flanges & Piping | Seals corrosive fluids (acids, solvents) in transport lines. |

| Valves & Instrumentation | Prevents fugitive emissions, ensures process control. |

| Pumps & Rotating Equipment | Withstands high pressure, protects equipment from leaks. |

| Reactors & Process Vessels | Maintains integrity in high-temperature/pressure reactions. |

Need a reliable PTFE seal for your chemical process? KINTEK specializes in manufacturing high-performance PTFE components, including custom gaskets, seals, and liners for the semiconductor, medical, laboratory, and industrial sectors. We deliver precision-engineered solutions from prototypes to high-volume orders, ensuring your equipment operates safely and efficiently. Contact us today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers