In industrial settings, PTFE envelope gaskets are most specifically applied where extreme chemical resistance must be combined with the mechanical sealing properties of a different core material. They are the go-to solution for sealing flanges on glass-lined steel vessels, plastic piping systems, and in pharmaceutical or food processing equipment where product purity is paramount.

The core value of a PTFE envelope gasket is that it provides the universal chemical inertness of a solid PTFE gasket while using a flexible inner core to mitigate PTFE's natural tendency to deform under pressure, a problem known as "cold flow."

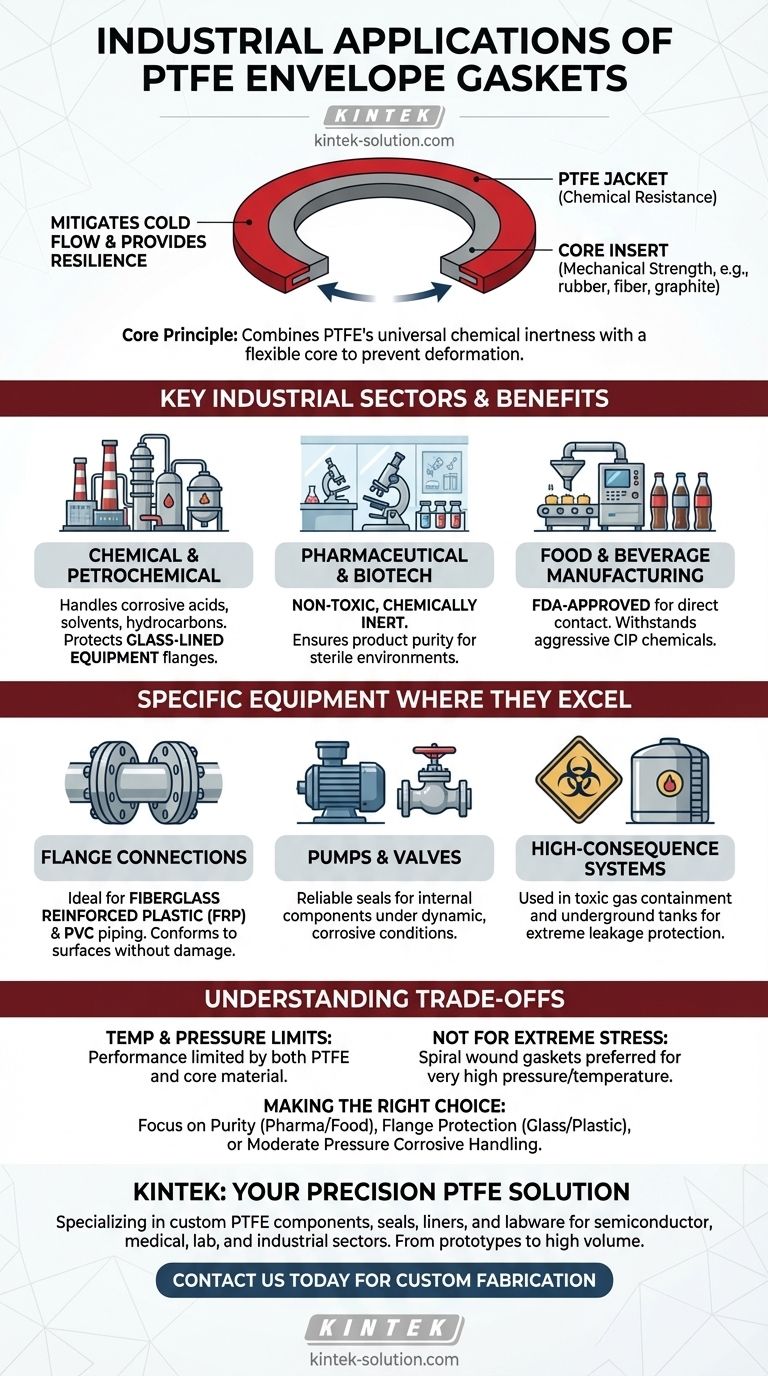

Core Principle: Why an "Envelope" Gasket?

To understand the specific applications of PTFE envelope gaskets, you must first understand their fundamental design principle. They are a composite gasket, engineered to leverage the strengths of two different materials.

The Unmatched Chemical Resistance of PTFE

Polytetrafluoroethylene (PTFE) is one of the most chemically inert materials used in industry. It is virtually immune to attack from aggressive acids, solvents, caustics, and other corrosive fluids.

This makes it an ideal material for the wetted surfaces of a seal—the parts that come into direct contact with the process media.

Overcoming PTFE's Mechanical Limitation: Cold Flow

The primary weakness of solid PTFE is cold flow, or creep. When subjected to the compressive force of a bolted flange, solid PTFE has a tendency to slowly deform and "flow" away from the point of highest pressure.

This deformation can lead to a loss of bolt torque and, eventually, a failed seal.

The Role of the Core Insert Material

The "envelope" design solves this problem. A thin jacket of pure PTFE encases a more mechanically robust and resilient core material, such as compressed non-asbestos fiber, rubber, or graphite.

The PTFE provides the chemical shield, while the inner core material provides the mechanical strength, compressibility, and recovery needed to maintain a tight, long-lasting seal under pressure.

Key Industrial Applications by Sector

The unique composite design makes these gaskets indispensable in several key industries where standard gaskets would quickly fail.

Chemical and Petrochemical Processing

PTFE envelope gaskets are a mainstay in chemical plants for handling a wide range of corrosive substances.

They are specified for use in piping systems and reactors that handle strong acids, hydrocarbons, and solvents. They are especially critical for sealing flanges on glass-lined equipment, where the soft PTFE jacket protects the fragile glass face from being cracked by a harder gasket material.

Pharmaceutical and Biotechnology

In these industries, preventing contamination is the primary goal. The non-toxic and chemically inert nature of PTFE ensures that nothing leaches from the gasket into the process media.

This makes them essential for sealing equipment in sterile environments, ensuring the purity and integrity of high-value products.

Food and Beverage Manufacturing

Similar to pharmaceuticals, the food and beverage industry requires materials that are safe for direct contact with consumables.

PTFE is FDA-approved for these applications. Envelope gaskets are frequently used in blending machines, piping, and storage tanks to provide a non-contaminating seal that can withstand aggressive clean-in-place (CIP) chemicals.

Specific Equipment Where They Excel

Beyond general industries, PTFE envelope gaskets are chosen to solve sealing challenges in specific types of equipment.

Flange Connections

Their primary application is in flanged joints, especially those involving dissimilar or delicate materials. They are the preferred choice for Fiberglass Reinforced Plastic (FRP) and PVC piping, as the soft PTFE conforms to surface imperfections without damaging the plastic flanges.

Pumps and Valves

The internal components of pumps and valves often require reliable seals that can withstand both corrosive media and the dynamic conditions of operation. Envelope gaskets provide a dependable sealing solution in these critical components.

High-Consequence Systems

For applications where a leak would be catastrophic, these gaskets offer an enhanced level of security. They are used in toxic gas containment systems and underground storage tanks where extreme leakage protection is a non-negotiable requirement.

Understanding the Trade-offs

While highly effective, PTFE envelope gaskets are not a universal solution. Understanding their limitations is key to proper application.

Temperature and Pressure Limits

The gasket's performance is limited by both the PTFE envelope and the core material. While PTFE has a wide operating temperature range, the core insert may have a much lower limit. The combination dictates the gasket's maximum pressure and temperature rating.

Not for Extreme Mechanical Stress

In very high-pressure and high-temperature services, such as those found in power generation or heavy refining, a spiral wound gasket is often a more suitable choice due to its superior mechanical strength and blowout resistance.

Importance of Proper Installation

The PTFE jacket is relatively thin and can be damaged by improper handling or installation. Overtightening or unevenly torquing the flange bolts can pinch the envelope, creating a potential leak path and compromising the seal.

Making the Right Choice for Your Application

Selecting the correct gasket requires matching its properties to your primary operational goal.

- If your primary focus is maximum chemical purity and inertness: Choose a PTFE envelope gasket for any pharmaceutical, biotech, or food-grade application where process media must not be contaminated.

- If your primary focus is protecting fragile flange faces: This is the ideal gasket for sealing glass-lined steel, plastic (FRP/PVC), or other delicate equipment flanges that could be damaged by a harder material.

- If your primary focus is handling highly corrosive media at moderate pressures: These gaskets provide the ultimate chemical resistance in standard chemical processing, especially when a solid metal gasket is not a viable option.

By understanding that this gasket is a precise solution to a specific engineering problem—combining chemical inertness with mechanical stability—you can deploy it with confidence in the applications where it truly excels.

Summary Table:

| Industry/Application | Key Benefit of PTFE Envelope Gasket |

|---|---|

| Chemical & Petrochemical | Extreme chemical resistance; protects glass-lined equipment |

| Pharmaceutical & Biotechnology | Non-toxic, inert; ensures product purity |

| Food & Beverage | FDA-approved; safe for consumables, withstands CIP chemicals |

| FRP/PVC Piping Systems | Conforms to imperfections without damaging flanges |

| Pumps & Valves | Reliable sealing under dynamic, corrosive conditions |

Need a reliable PTFE sealing solution for your industrial equipment? KINTEK specializes in manufacturing high-precision PTFE components, including custom envelope gaskets, seals, liners, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors with custom fabrication from prototypes to high-volume orders. Our expertise ensures your equipment achieves optimal performance and longevity. Contact us today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components