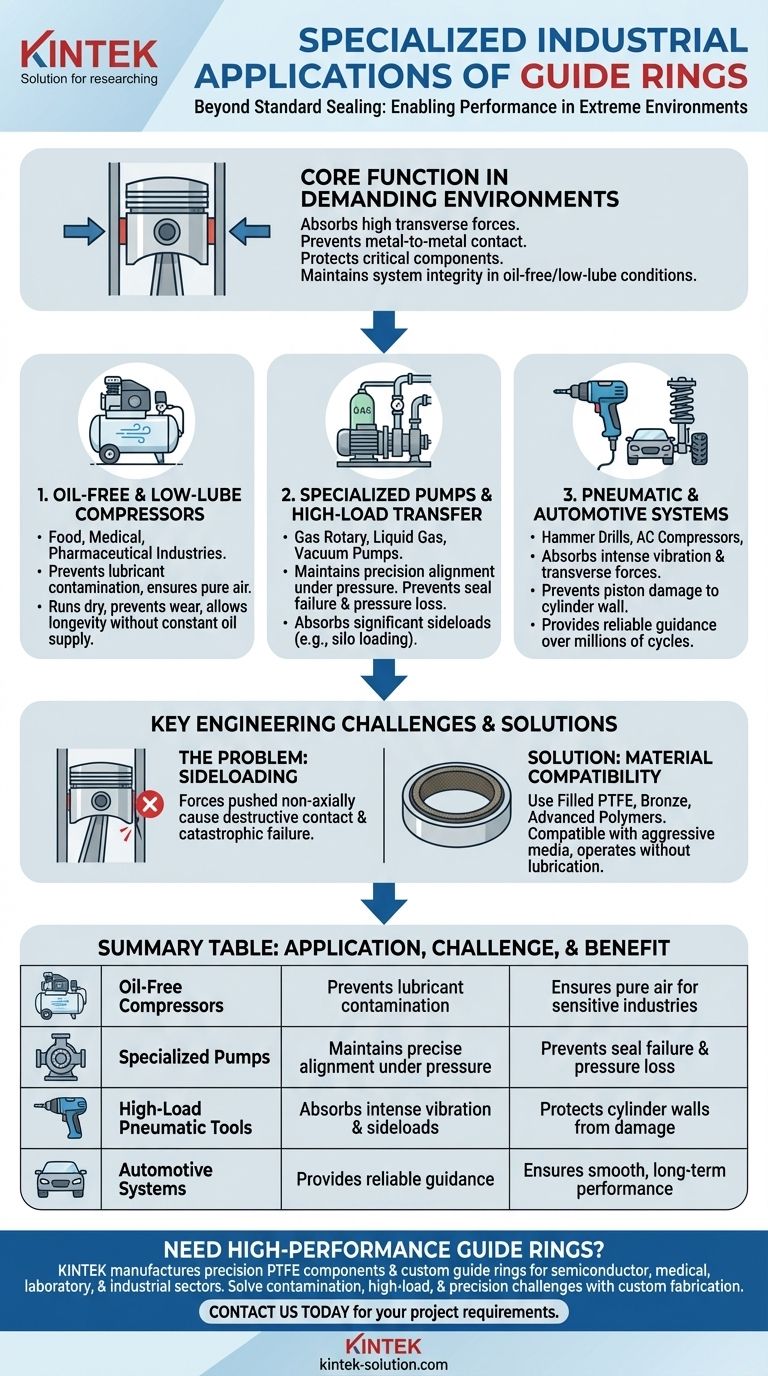

Beyond standard sealing, specialized industrial applications for guide rings focus on environments where traditional lubrication is limited or contamination is unacceptable. Key uses include oil-free compressors for the food and pharmaceutical industries, various pumps handling liquid gas or vacuums, high-load pneumatic tools like hammer drills, and precision automotive systems such as air conditioning and ride leveling.

The core value of guide rings in specialized applications is their ability to absorb high transverse forces and prevent metal-to-metal contact. This protects critical components and maintains system integrity, especially in oil-free or low-lubrication environments where conventional bearings would fail.

The Core Function in Demanding Environments

In any hydraulic or pneumatic system, the primary role of a guide ring is to guide the piston and rod, preventing direct contact with the cylinder bore. This becomes critically important in specialized applications where operating conditions are extreme.

In Compressors (Oil-Free and Low-Lube)

Guide rings are essential for oil-free compressed air generation, particularly in the food, medical, and pharmaceutical industries.

In these systems, any lubricant contamination is unacceptable. Guide rings made from self-lubricating materials allow the compressor to run dry, preventing wear between the piston and cylinder while ensuring the air remains pure.

They also perform exceptionally well in low-lube conditions, where only minimal lubrication is present, ensuring system longevity without relying on a constant oil supply.

For Specialized Pumps and High-Load Transfer

Systems like gas rotary pumps, liquid gas pumps, and vacuum pumps require precise, consistent alignment to function efficiently.

Guide rings maintain the tight tolerances necessary for these applications, preventing misalignment that could compromise seals and lead to pressure loss or system failure.

Similarly, in rotary compressors used for silo loading and unloading, guide rings absorb the significant sideloads generated, protecting the primary seals and piston from damage.

In Pneumatic and Automotive Systems

High-impact tools like pneumatic hammer drills generate intense vibration and transverse forces. A guide ring is crucial for absorbing these loads, preventing the piston from damaging the cylinder wall.

In automotive systems like ride leveling and air-conditioning compressors, guide rings provide the long-term, reliable guidance needed for smooth, consistent performance over millions of cycles.

Understanding the Key Engineering Challenge

The decision to use a specialized guide ring is driven by engineering challenges that standard components cannot solve. The primary issue is preventing destructive contact under adverse conditions.

The Problem of Sideloading

In many systems, forces are not perfectly axial. Sideloads, or transverse forces, push the piston or rod against the cylinder wall.

Without a guide ring, this force would be concentrated on a small metal edge, causing galling, scoring, and eventual catastrophic failure of both the components and the seals.

The Challenge of Material Compatibility

Guide rings are manufactured from a range of materials, such as filled PTFE, bronze, or advanced polymers.

This allows engineers to select a material that is compatible with the system's media (e.g., aggressive chemicals, gases) and can operate without lubrication, solving problems that traditional metallic bearings cannot.

Making the Right Choice for Your Goal

Selecting the right component depends entirely on the primary challenge you need to solve.

- If your primary focus is preventing contamination: Use guide rings in oil-free compressors for sensitive industries like food, pharma, or medical device manufacturing.

- If your primary focus is managing high loads and vibration: Implement robust guide rings in pneumatic tools, heavy-duty compressors, and off-highway equipment to absorb destructive transverse forces.

- If your primary focus is ensuring long-term precision: Rely on guide rings in automotive systems, vacuum pumps, and gas handling equipment to maintain critical alignment and efficiency.

Ultimately, the guide ring is a critical enabler, allowing machinery to perform reliably in environments where it would otherwise quickly fail.

Summary Table:

| Application Area | Key Challenge Solved | Primary Benefit |

|---|---|---|

| Oil-Free Compressors | Prevents lubricant contamination | Ensures pure air for food, pharma, and medical industries |

| Specialized Pumps (Gas, Vacuum, Liquid) | Maintains precise alignment under pressure | Prevents seal failure and pressure loss |

| High-Load Pneumatic Tools (e.g., Hammer Drills) | Absorbs intense vibration and sideloads | Protects cylinder walls from damage |

| Automotive Systems (e.g., AC, Ride Leveling) | Provides reliable guidance over millions of cycles | Ensures smooth, long-term performance |

Need high-performance guide rings for your specialized application?

KINTEK manufactures precision PTFE components, including custom guide rings, for the semiconductor, medical, laboratory, and industrial sectors. We help you solve contamination, high-load, and precision alignment challenges with custom fabrication from prototypes to high-volume orders.

Contact us today to discuss your project requirements and ensure reliable performance in your most demanding systems!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability