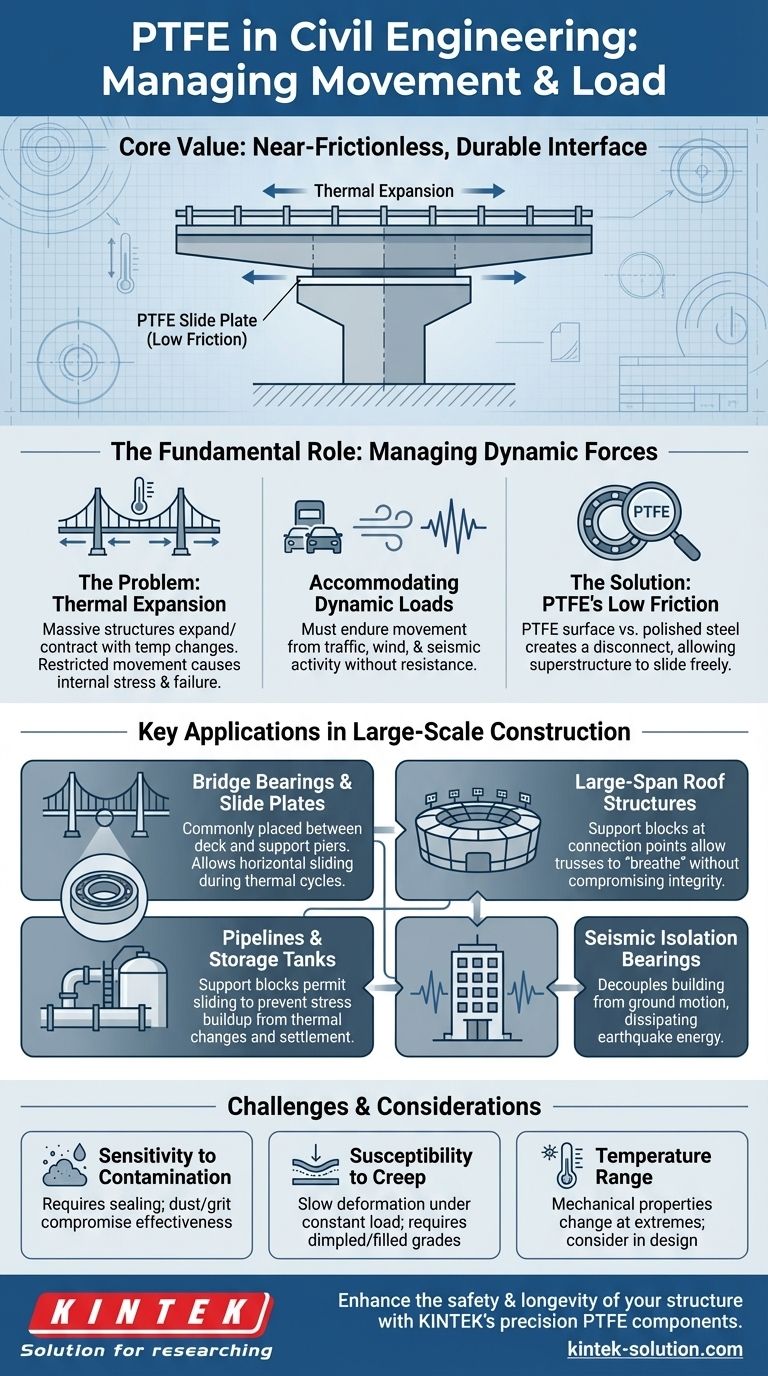

In civil engineering, Polytetrafluoroethylene (PTFE) is most critically used as a core component in structural bearings and slide plates. These components are essential for bridges, large-span roof trusses, tunnels, and heavy industrial structures like pipelines and storage tanks, allowing them to manage immense forces from thermal expansion, contraction, and other dynamic loads.

The core value of PTFE in civil engineering is its ability to create a near-frictionless, durable interface between massive structural elements. This allows structures to safely expand, contract, and shift under load without transferring destructive stress to their foundations.

The Fundamental Role of PTFE: Managing Movement and Load

Large civil engineering projects are not static. They are dynamic systems that must be designed to move in controlled ways to ensure their structural integrity and longevity.

The Problem of Thermal Expansion

Massive structures made of steel and concrete expand and contract significantly with daily and seasonal temperature changes. A long steel bridge, for example, can change in length by several feet.

If this movement were restricted, it would generate enormous internal stress, potentially leading to cracks, buckling, and catastrophic failure of the support columns or foundations.

Accommodating Dynamic Loads

Beyond thermal changes, structures must also endure movement from traffic, wind, and seismic activity. These dynamic loads require a system that can absorb or accommodate motion without resistance.

Why PTFE is the Solution

PTFE's extremely low coefficient of friction is the key. By creating a bearing with a PTFE surface sliding against a polished stainless steel plate, engineers introduce a disconnect.

This allows the superstructure (e.g., the bridge deck) to slide freely over the substructure (e.g., the support pier), accommodating movement with minimal stress transfer.

Key Applications in Civil Engineering

The principle of using PTFE to create a low-friction sliding surface is applied across several critical areas of large-scale construction.

Bridge Bearings and Slide Plates

This is the most common application. Bridge bearings, often taking the form of slide plates, brackets, or swivels, are placed between the bridge deck and the support piers. A sheet of PTFE allows the deck to move horizontally as it expands and contracts.

Large-Span Roof Structures

The steel trusses used in stadiums, airports, and convention centers are subject to significant thermal movement. PTFE support sliding blocks are placed at the connection points between the roof and its support columns, allowing the structure to "breathe" without compromising its integrity.

Pipelines and Storage Tanks

Long chemical pipelines and massive storage tanks expand and contract with temperature changes and can also shift due to ground settlement. Placing PTFE support blocks at regular intervals allows the structure to slide, preventing stress buildup at connection points and nozzles.

Understanding the Trade-offs and Limitations

While highly effective, using PTFE in structural applications is not without its challenges. The design must account for the material's specific properties.

Sensitivity to Contamination

The low-friction performance of a PTFE bearing is highly dependent on a clean interface. Dust, grit, and moisture can compromise its effectiveness. For this reason, these bearings are almost always encapsulated or sealed to protect the sliding surfaces.

Susceptibility to Creep

Under a constant, heavy load, PTFE can slowly deform over time—a phenomenon known as creep. Engineers must account for this by using dimpled PTFE surfaces to manage lubricant and control pressure, or by specifying reinforced or "filled" grades of PTFE that have higher compressive strength.

Temperature Range

While PTFE has an excellent service temperature range, its mechanical properties can change at extreme highs or lows. This must be considered in the design phase for projects in unusually harsh climates.

How to Apply This to Your Project

Your specific goal will determine how PTFE is integrated into the structural design.

- If your primary focus is accommodating thermal expansion in bridges or roofs: PTFE slide bearings are the industry standard for creating a reliable, low-friction disconnect between the superstructure and substructure.

- If your primary focus is supporting heavy, settling structures like tanks or pipelines: PTFE support blocks are the most effective method for allowing movement from thermal cycles and ground settlement, preventing stress concentration.

- If your primary focus is seismic protection: PTFE is a core component in seismic isolation bearings, which are designed to decouple a building from ground motion and dissipate energy during an earthquake.

Ultimately, integrating PTFE into a structural design is a strategic decision to manage immense forces, ensuring the longevity and safety of critical infrastructure.

Summary Table:

| Application | Primary Function of PTFE |

|---|---|

| Bridge Bearings | Allows horizontal sliding of bridge decks over piers to manage thermal expansion/contraction. |

| Roof Support Blocks | Enables large-span steel roof trusses to move freely at support columns. |

| Pipeline/Tank Supports | Prevents stress buildup by allowing structures to shift from thermal cycles and settlement. |

| Seismic Bearings | Acts as a low-friction surface in systems that isolate structures from earthquake motion. |

Need high-performance PTFE components for your civil engineering project?

KINTEK specializes in manufacturing precision PTFE seals, liners, bearings, and custom components for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a solution tailored to manage movement, load, and environmental challenges.

Contact KINTEK today to discuss how our PTFE components can enhance the safety and longevity of your structure.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications