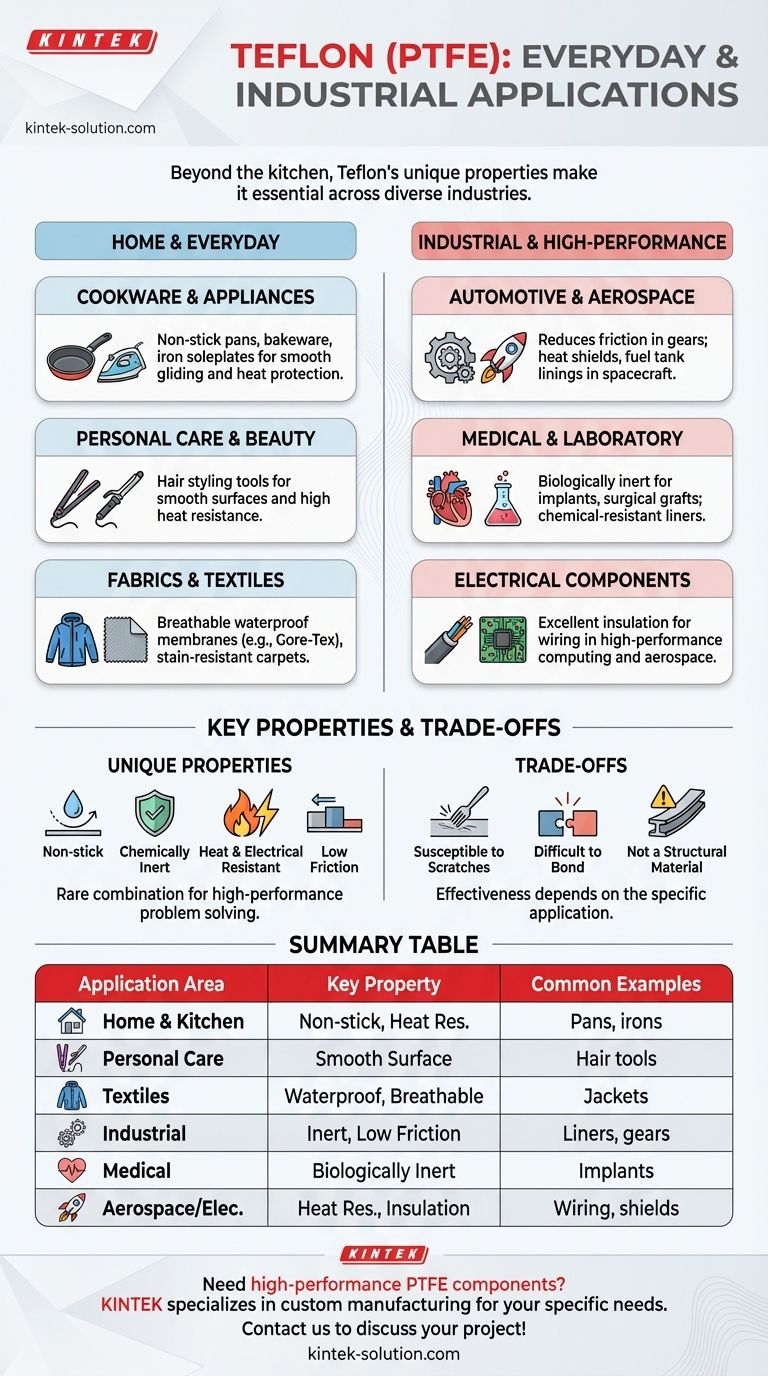

Beyond its famous role in the kitchen, Teflon is one of the most versatile materials in modern life, found in everything from your waterproof jacket and hair straightener to medical implants and aerospace components. Its widespread use stems from a unique combination of properties that solve problems across dozens of unrelated industries.

The core reason Teflon is so ubiquitous is not just one feature, but its rare combination of being almost entirely non-stick, chemically inert, and highly resistant to both heat and electricity. This makes it a high-performance problem solver in both household and industrial settings.

In the Home: Beyond the Frying Pan

While non-stick cookware is Teflon's most recognized application, its properties make it invaluable in many other consumer products that prioritize smooth surfaces, heat protection, and durability.

Cookware and Kitchen Appliances

The classic use for polytetrafluoroethylene (PTFE), or Teflon, is as a non-stick coating on pans, pots, and bakeware. It is also used on the soleplates of clothing irons to prevent them from sticking to or burning fabrics.

Personal Care and Beauty

Teflon's ability to create a smooth, heat-resistant surface is leveraged in hair styling tools like straighteners and curling irons. It allows the tools to glide through hair without snagging while withstanding high temperatures. It is even used in some nail polishes to provide a smooth, protected finish.

Fabrics and Textiles

Many stain-resistant carpets and waterproof fabrics rely on Teflon. Materials like Gore-Tex incorporate a thin membrane of PTFE to block water from entering while allowing vapor to escape. This creates breathable yet fully waterproof outerwear.

Industrial and High-Performance Applications

Teflon's resilience in extreme conditions makes it a critical component in fields where failure is not an option. Its performance goes far beyond what is required in a typical home.

Automotive and Aerospace

In cars, Teflon coatings are used on parts like gears and bearings to reduce friction, minimize wear and tear, and ensure smooth operation. In aerospace, it serves as a crucial material for heat shields, fuel tank linings, and even the nose cones of spacecraft due to its incredible heat resistance.

Medical and Laboratory Use

Because Teflon is chemically inert, it does not react with bodily tissues, making it ideal for biomedical applications. It is used in surgical grafts, artificial heart valves, and as a coating on medical tools. This same non-reactive property makes it perfect for lining pipes and containers in laboratories that handle corrosive chemicals.

Electrical Components

Teflon is an excellent electrical insulator. This property makes it a preferred material for insulating wiring and cables, especially in high-performance computer and aerospace applications where signal integrity and heat resistance are critical.

Understanding the Trade-offs

While incredibly useful, Teflon's unique properties also create certain limitations that are important to understand. Its effectiveness depends entirely on the application.

Surface Durability

The primary drawback of Teflon as a coating, especially in cookware, is its susceptibility to scratches. Using metal utensils can easily damage the non-stick surface, compromising its performance and longevity.

Application Challenges

The very non-stick quality that makes Teflon so valuable also makes it difficult to bond to other materials. Applying it as a coating requires special surface preparation and industrial processes to ensure it adheres properly.

Not a Structural Material

Teflon is almost always used as a coating, liner, or specialized part rather than a primary structural component. It lacks the rigidity and strength needed for load-bearing applications.

How to Recognize Teflon's Role

You can identify the need for Teflon by its function. Its use is a direct solution to a specific set of problems.

- If your primary focus is preventing sticking: Teflon is the ideal choice for cookware, heat presses, and industrial molds.

- If your primary focus is reducing friction and wear: Its low-friction surface is essential for gears, bearings, and other moving mechanical parts.

- If your primary focus is resisting chemicals or extreme temperatures: Its inertness and thermal stability make it vital for laboratory equipment, aerospace components, and electrical insulation.

Ultimately, Teflon's value lies in its silent ability to make countless products safer, more durable, and more efficient.

Summary Table:

| Application Area | Key Teflon (PTFE) Property | Common Examples |

|---|---|---|

| Home & Kitchen | Non-stick, Heat Resistance | Non-stick pans, iron soleplates, bakeware |

| Personal Care | Smooth Surface, Heat Resistance | Hair straighteners, curling irons |

| Textiles | Waterproof, Breathable | Waterproof jackets (Gore-Tex), stain-resistant carpets |

| Industrial | Chemical Inertness, Low Friction | Laboratory liners, chemical pipes, bearings, gears |

| Medical | Biologically Inert | Surgical grafts, heart valves, tool coatings |

| Aerospace/Electrical | High Heat Resistance, Insulation | Wiring insulation, spacecraft heat shields |

Need high-performance PTFE components for your application?

KINTEK specializes in the precision manufacturing of custom PTFE (Teflon) seals, liners, labware, and other critical components. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we can help you leverage Teflon's unique properties to solve your most challenging problems.

We offer custom fabrication from prototypes to high-volume orders, ensuring the perfect fit and performance for your needs.

Contact KINTEK today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs