Beyond the frying pan, the uses of Teflon are remarkably diverse, spanning critical applications in medicine, aerospace, and heavy industry. While best known for non-stick cookware, its unique properties make it an essential material for things like medical implants, electrical wire insulation, industrial seals and bearings, and protective coatings on spacecraft.

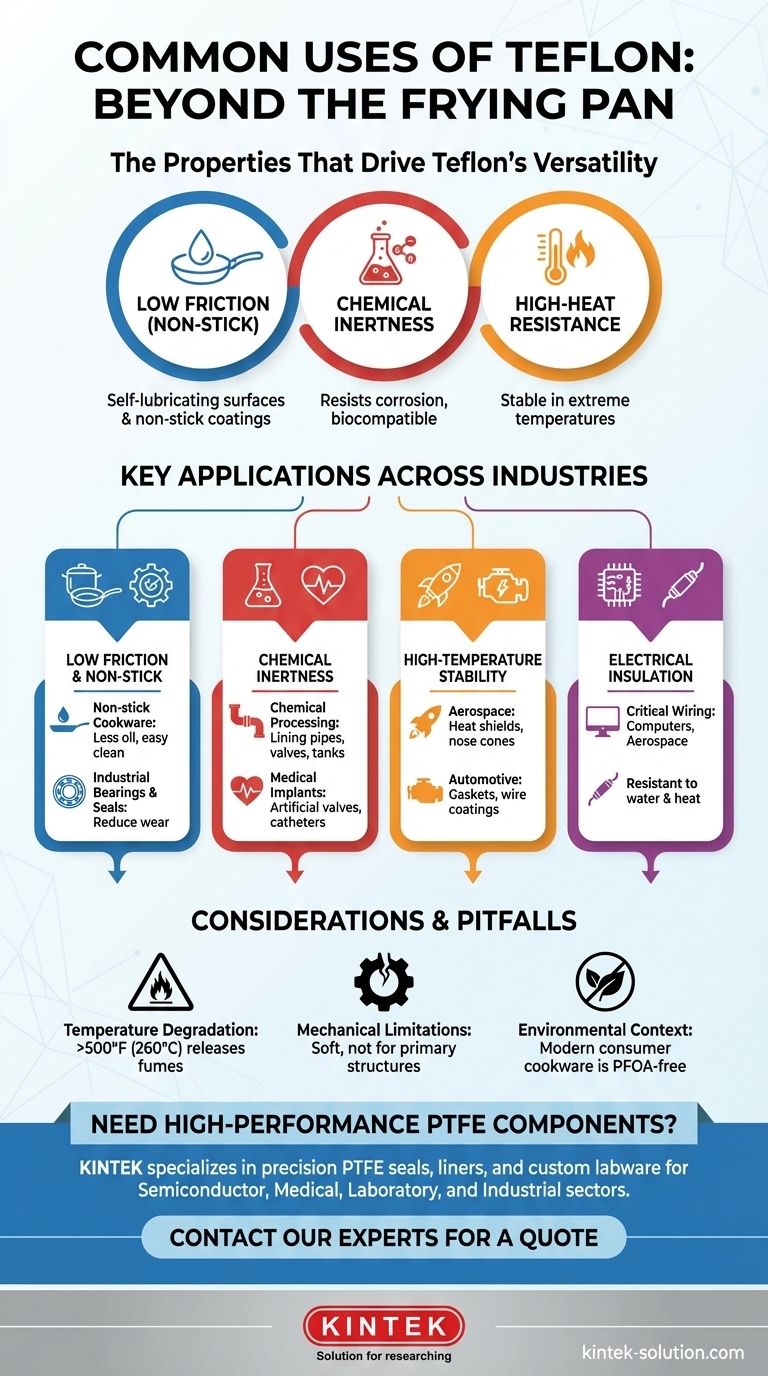

Teflon's versatility is not due to a single feature, but rather a powerful combination of three core properties: an extremely low coefficient of friction (making it non-stick), exceptional chemical inertness (making it non-reactive), and high heat resistance. Understanding these principles is the key to seeing why it appears in so many unrelated fields.

The Properties That Drive Teflon's Versatility

Teflon is the brand name for Polytetrafluoroethylene (PTFE), a synthetic fluoropolymer. Its molecular structure gives it a unique set of characteristics that engineers and designers leverage to solve complex problems.

The Power of Low Friction (Non-Stick)

The most famous property of Teflon is its incredibly low friction, one of the lowest of any solid material. This means other substances rarely stick to it.

This is the principle behind non-stick cookware, which allows for cooking with less oil and easier cleanup. In industrial settings, this same property is used to create self-lubricating bearings, gaskets, and seals that reduce wear and tear on machinery.

Unmatched Chemical Inertness

Teflon is highly non-reactive and resists corrosion from the vast majority of chemicals. This chemical stability, or inertness, makes it invaluable in harsh environments.

It is used to line pipes, valves, and storage tanks that handle corrosive acids and chemicals. This same property makes it biocompatible, meaning the human body does not react to it, making it ideal for medical implants like artificial heart valves, catheters, and surgical coatings.

High-Temperature Stability

Teflon can withstand a wide range of temperatures without degrading, maintaining its properties in both high-heat and cryogenic conditions.

This makes it suitable not only for cookware but also for high-performance applications. In the aerospace industry, it's used in heat shields and nose cones on spacecraft. In the automotive sector, it's found in gaskets and wire coatings that must endure high engine temperatures.

Superior Electrical Insulation

Teflon is an excellent electrical insulator, meaning it does not conduct electricity. It is also resistant to water, which can compromise insulating materials.

This makes it a preferred material for insulating electrical wires and cables, especially in demanding applications like computers, aerospace, and automotive wiring where signal integrity and fire safety are critical.

Common Pitfalls and Considerations

While Teflon is a powerful material, its application is not without trade-offs. Understanding its limitations is crucial for proper use.

Temperature Degradation

While highly heat-resistant, Teflon does have an upper temperature limit. When heated above approximately 500°F (260°C), it can begin to degrade and release fumes. This is a critical design consideration, particularly in cookware and industrial applications.

Mechanical Limitations

Teflon is a relatively soft material. While this is advantageous for creating tight seals in gaskets, it means Teflon is not used for primary structural components. It is most often used as a coating, liner, or specialized part where its unique properties are paramount.

Environmental Context

The manufacturing of early forms of Teflon involved a processing aid called PFOA, which raised environmental and health concerns. It is important to note that modern consumer cookware made with Teflon is PFOA-free. However, the broader class of chemicals (PFAS) to which Teflon belongs is known for its environmental persistence.

Making the Right Choice for Your Goal

The decision to use Teflon is driven by which of its core properties best solves your specific problem.

- If your primary focus is reducing friction: Teflon is an industry standard for creating non-stick surfaces and self-lubricating mechanical parts like bearings and seals.

- If your primary focus is chemical resistance: Its inertness makes it the ideal choice for lining pipes, tanks, and laboratory equipment, or for creating biocompatible medical devices.

- If your primary focus is insulation in extreme environments: Teflon-coated wires are essential in demanding aerospace, automotive, and electrical applications where heat and chemical resistance are critical.

Ultimately, recognizing Teflon as a high-performance engineering material—not just a kitchen convenience—unlocks its true potential across countless industries.

Summary Table:

| Key Property | Primary Applications |

|---|---|

| Low Friction (Non-Stick) | Non-stick coatings, self-lubricating bearings, seals, and gaskets. |

| Chemical Inertness | Chemical tank linings, pipes, valves, and biocompatible medical implants. |

| High-Temperature Stability | High-performance gaskets, wire coatings, and aerospace heat shields. |

| Electrical Insulation | Insulation for critical wiring in computers, aerospace, and automotive systems. |

Need High-Performance PTFE Components?

At KINTEK, we specialize in manufacturing precision PTFE components—from seals and liners to custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a prototype or a high-volume order, our custom fabrication expertise ensures you get the exact solution to leverage Teflon's unique properties.

Contact our experts today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency