The most common fillers for PTFE are glass fiber, carbon, graphite, and bronze, which are added to improve properties that pure PTFE lacks, such as wear resistance, strength, and thermal conductivity. These additives transform PTFE from a soft, compliant material into a robust engineering plastic suitable for demanding mechanical applications.

Virgin PTFE is an exceptional material for its low friction and chemical inertness, but it is mechanically weak and prone to deforming under load. Fillers are the essential ingredients that provide the specific strength, wear resistance, and thermal properties required for a given application.

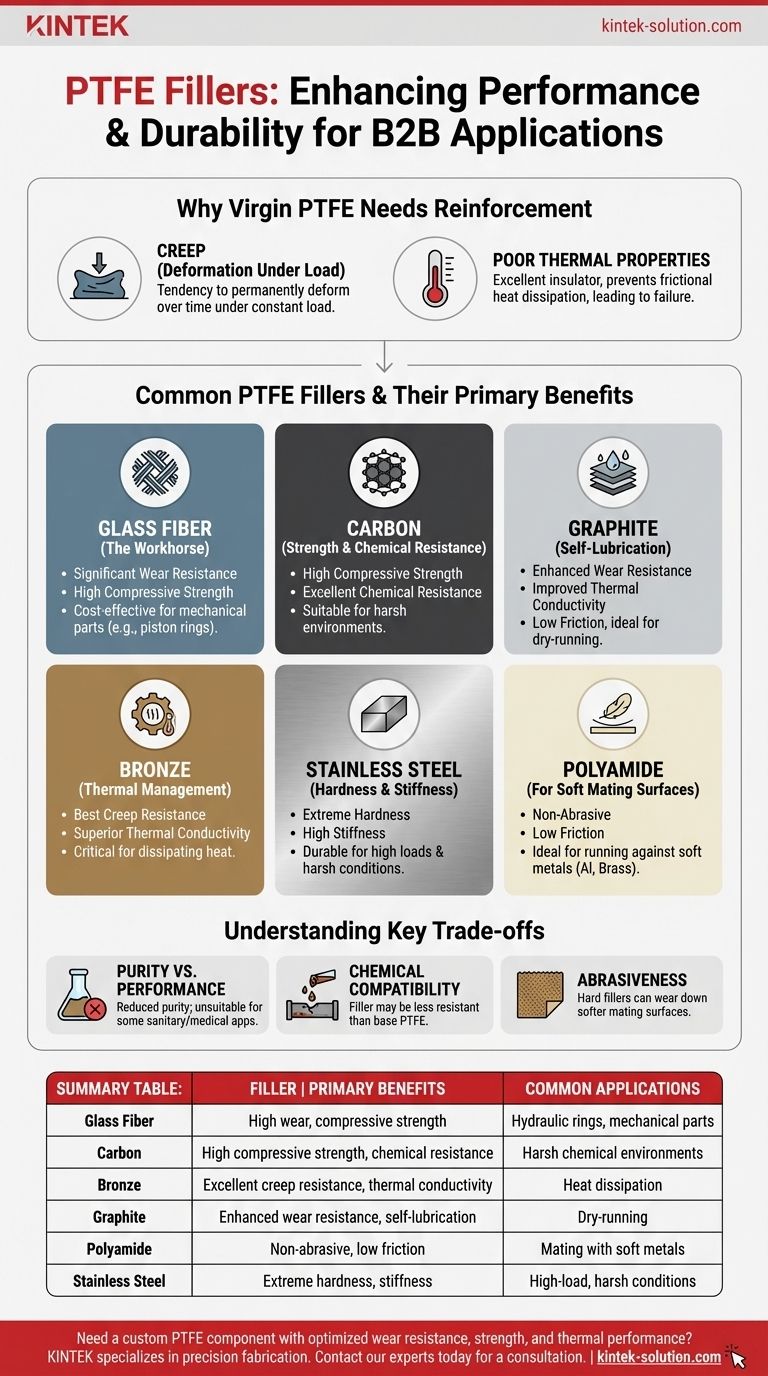

Why Virgin PTFE Needs Reinforcement

Polytetrafluoroethylene (PTFE) is a remarkable polymer, but its inherent softness creates significant limitations in mechanical systems. Understanding these weaknesses is key to appreciating the role of fillers.

The Problem of Creep

Virgin PTFE has poor resistance to creep, which is the tendency of a material to deform permanently over time when subjected to a constant load. Under pressure, pure PTFE will slowly cold-flow out of its intended shape.

Poor Thermal Properties

PTFE is an excellent thermal insulator. While useful in some cases, this property prevents it from dissipating frictional heat in dynamic applications like bearings or seals, which can lead to premature failure.

The Role of Fillers

Fillers are added to the PTFE matrix to create a composite material. These additives act as a reinforcing skeleton, drastically improving the mechanical and thermal properties of the base polymer.

A Guide to Common PTFE Fillers

The choice of filler is dictated entirely by the demands of the application. Each type provides a unique set of enhancements.

Glass Fiber (The Workhorse)

Glass is the most widely used filler for PTFE. It provides a significant and cost-effective improvement in wear resistance and compressive strength, reducing deformation under load. It is a common choice for applications like hydraulic piston rings.

Carbon (For Strength and Chemical Resistance)

Adding carbon dramatically increases compressive strength and load-bearing capabilities. Carbon-filled PTFE offers excellent resistance to pressure and is suitable for use in harsh chemical environments. It is often combined with graphite for enhanced properties.

Graphite (For Self-Lubrication)

Graphite is primarily used to enhance wear resistance and thermal conductivity. It is a lubricating filler, which helps reduce the coefficient of friction, especially in start-stop or dry-running applications.

Bronze (For Thermal Management)

Bronze provides the best improvement in creep resistance and thermal conductivity. This makes it the ideal choice for applications where dissipating heat is critical to prevent thermal expansion and failure.

Stainless Steel (For Hardness)

For applications requiring extreme hardness and stiffness, stainless steel powder is used as a filler. This creates a very durable material capable of withstanding high loads and harsh conditions.

Polyamide (For Mating with Soft Metals)

Polyamide is a polymer filler known for its low friction coefficient. Its key advantage is that it is non-abrasive, making it ideal for applications where the PTFE component will be running against softer surfaces like stainless steel, aluminum, or brass.

Understanding the Trade-offs

Adding fillers to PTFE is not without compromise. Enhancing one property often means sacrificing another.

Purity vs. Performance

The most obvious trade-off is purity. Filled PTFE materials do not maintain the same high level of purity as virgin PTFE. This makes them unsuitable for certain sanitary, medical, or semiconductor applications.

Chemical Compatibility

While PTFE itself is nearly universally inert, the filler material may not be. The chemical resistance of the composite is limited by the least resistant material in the blend. For instance, bronze-filled PTFE is not suitable for use with strong acids or bases that would corrode the bronze.

Abrasiveness to Mating Surfaces

Hard fillers like glass fiber can be abrasive to softer mating surfaces. Over time, a glass-filled PTFE seal can wear down a softer metal shaft, making a non-abrasive filler like polyamide a better choice in those scenarios.

Selecting the Right Filled PTFE for Your Application

Your choice of filler should be a direct response to the primary challenge your component will face.

- If your primary focus is high wear resistance and compressive strength: Glass-filled PTFE is the most common and cost-effective solution.

- If your primary focus is thermal conductivity and creep resistance: Bronze-filled PTFE is the superior option for managing heat and heavy loads.

- If your primary focus is strength in harsh chemical environments: Carbon-filled PTFE provides an excellent balance of chemical and mechanical performance.

- If your primary focus is running against soft metal surfaces: Polyamide-filled PTFE offers low friction without causing abrasion to the mating component.

Ultimately, choosing the correct filled PTFE compound transforms a good design into a reliable and long-lasting one.

Summary Table:

| Filler Type | Primary Benefits | Common Applications |

|---|---|---|

| Glass Fiber | High wear resistance, compressive strength | Hydraulic piston rings, general mechanical parts |

| Carbon | High compressive strength, chemical resistance | Harsh chemical environments, high-load applications |

| Bronze | Excellent creep resistance, thermal conductivity | Applications requiring heat dissipation |

| Graphite | Enhanced wear resistance, self-lubrication | Dry-running or start-stop applications |

| Polyamide | Non-abrasive, low friction | Mating with soft metals (aluminum, brass) |

| Stainless Steel | Extreme hardness, stiffness | High-load, harsh condition applications |

Need a custom PTFE component that balances wear resistance, strength, and thermal performance?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—reinforced with the right fillers for your specific application. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we provide custom fabrication from prototypes to high-volume orders to ensure optimal performance and longevity.

Let us help you select the ideal filled PTFE compound for your needs. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F