In short, PTFE seals are used in demanding applications where standard elastomer seals would fail due to aggressive chemicals, extreme temperatures, or high pressure. You will find them in everything from aerospace engines and chemical processing pumps to medical devices and food manufacturing equipment.

The core reason for choosing a Polytetrafluoroethylene (PTFE) seal is its unique combination of material properties. It is the go-to solution for sealing challenges that involve conditions too hostile for conventional rubber or plastic materials.

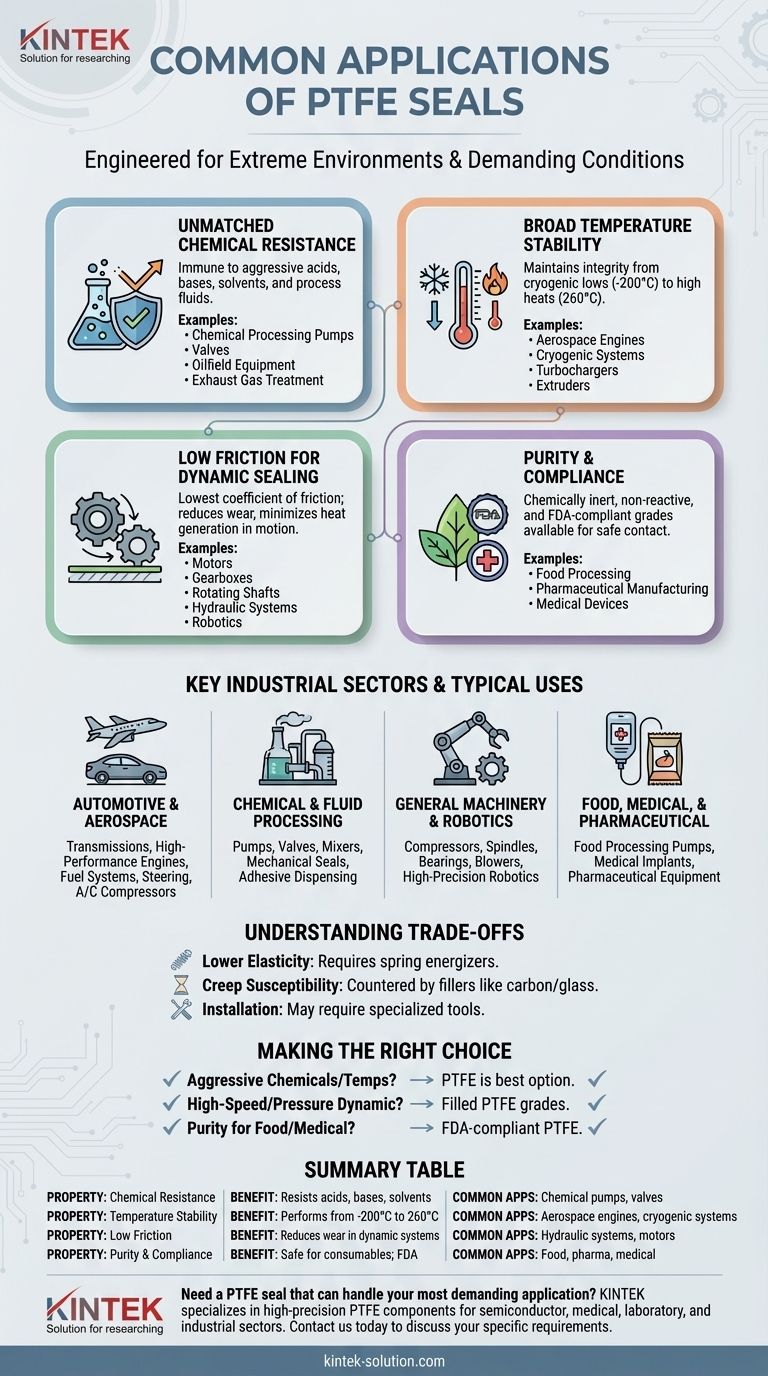

Why PTFE is the Material of Choice for Extreme Environments

The widespread application of PTFE seals isn't accidental. It stems directly from a set of properties that make it a superior choice for sealing in critical and demanding systems. Understanding these properties is key to understanding its use cases.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert materials known. It is virtually immune to attack from aggressive acids, bases, solvents, and process fluids.

This makes it indispensable in applications like chemical processing pumps, valves, oilfield equipment, and exhaust gas treatment systems where other materials would quickly degrade and fail.

Broad Temperature Stability

PTFE seals maintain their integrity and sealing capability across an exceptionally wide temperature range, typically from cryogenic lows (-200°C) up to high heats (260°C).

This stability is critical for aerospace applications like aircraft engines and brake systems, as well as for cryogenic systems and high-temperature equipment like turbochargers and extruders.

Low Friction for Dynamic Sealing

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This is a significant advantage in dynamic sealing applications.

In motors, gearboxes, rotating shafts, and hydraulic systems, this low friction reduces wear, minimizes heat generation, and allows for higher surface speeds without seal failure.

Purity and Compliance

Certain grades of PTFE are compliant with stringent regulations, such as those from the FDA, making them safe for direct contact with consumables.

This is why PTFE seals are a mainstay in the food processing, pharmaceutical, and medical device industries. Their inert nature ensures they do not contaminate the product.

A Look at Key Industrial Applications

While the list is extensive, most applications for PTFE seals can be grouped into several major industrial categories.

Automotive and Aerospace

This sector requires high reliability under intense conditions. PTFE seals are used in transmissions, high-performance engines, fuel injection pumps, steering systems, and air conditioning compressors to handle heat, pressure, and aggressive fluids.

Chemical and Fluid Processing

This is a primary market for PTFE due to the constant exposure to corrosive materials. Common uses include pumps, valves, mixers, mechanical seals, and adhesive dispensing equipment.

General Machinery and Robotics

The need for reliable, long-life dynamic seals makes PTFE a frequent choice. It is found in compressors, spindles, bearings, blowers, and high-precision robotics where smooth, low-wear operation is critical.

Food, Medical, and Pharmaceutical

In these highly regulated industries, preventing contamination is paramount. PTFE is used in food processing pumps, medical implants, and pharmaceutical manufacturing equipment because it is cleanable, non-reactive, and compliant.

Understanding the Trade-offs

No material is perfect for every situation. Being a trusted advisor means acknowledging the limitations of PTFE to ensure its proper application.

Lower Elasticity vs. Elastomers

Unlike rubber o-rings, PTFE is a relatively rigid plastic. It does not have the same "bounce-back" memory as elastomers.

This means it is less forgiving of surface imperfections on hardware. To compensate, many PTFE seals incorporate a spring energizer to provide a constant outward force, ensuring a tight seal even at low pressures.

Susceptibility to Creep

Standard, unfilled PTFE can be prone to "creep," or slow deformation, when under a constant load.

To counteract this, PTFE is often blended with fillers like carbon, glass fiber, or bronze. These additives significantly improve creep resistance, wear resistance, and dimensional stability for more demanding applications.

Installation Considerations

The rigidity of PTFE can make installation more challenging than with a flexible rubber seal. Specialized tools and procedures are sometimes required to install the seal without damaging it or the housing.

Making the Right Choice for Your Goal

Selecting the right seal depends entirely on the primary challenge you need to solve.

- If your primary focus is handling aggressive chemicals or extreme temperatures: PTFE is almost certainly your best option, as most elastomers will degrade under these conditions.

- If your primary focus is sealing a high-speed or high-pressure dynamic system: The low-friction and wear-resistant properties of filled PTFE grades make them a superior choice for ensuring long service life.

- If your primary focus is ensuring purity for food or medical applications: Specify an FDA-compliant grade of PTFE for its inertness and inability to contaminate the process media.

Ultimately, PTFE seals are engineered solutions for problems that lie beyond the capabilities of conventional sealing materials.

Summary Table:

| Key Property | Primary Benefit | Common Applications |

|---|---|---|

| Chemical Resistance | Resists aggressive acids, bases, and solvents | Chemical pumps, valves, oilfield equipment |

| Temperature Stability | Performs from -200°C to 260°C | Aerospace engines, cryogenic systems, turbochargers |

| Low Friction | Reduces wear in dynamic systems | Hydraulic systems, motors, gearboxes, robotics |

| Purity & Compliance | Safe for consumables; FDA-compliant grades available | Food processing, pharmaceutical, medical devices |

Need a PTFE seal that can handle your most demanding application?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your seals are engineered to withstand extreme chemicals, temperatures, and pressures while maintaining purity and compliance.

Whether you need a custom prototype or high-volume production, we deliver solutions that enhance reliability and longevity in your critical systems.

Contact us today to discuss your specific requirements and get a quote tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- What are the benefits of using PTFE seals? Unmatched Chemical & Temperature Resistance

- What are the advantages of PTFE-based seals? Unmatched Performance in Extreme Conditions

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What are the two temperature extremes discussed for PTFE seals? Maximize Performance from Cryogenic to High-Heat