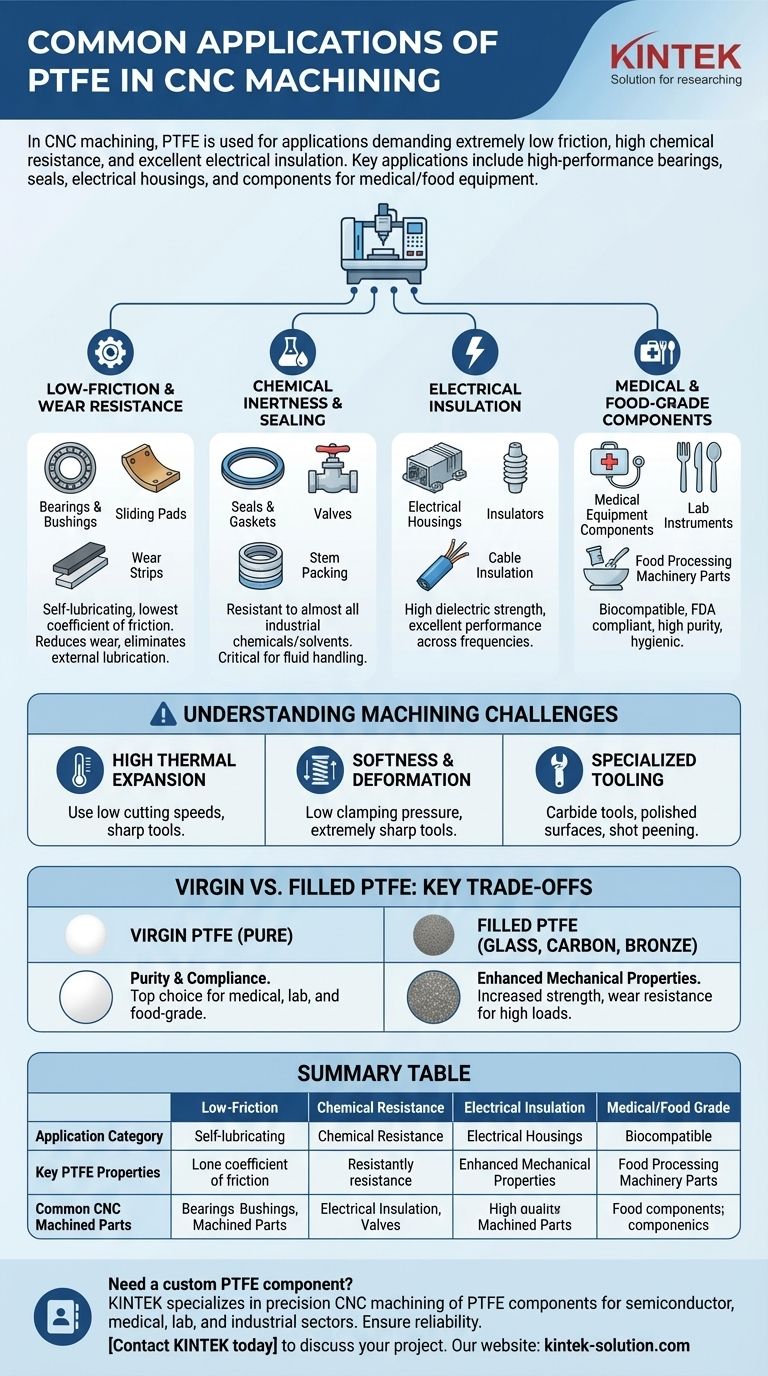

In CNC machining, PTFE is primarily used for applications that demand extremely low friction, high chemical resistance, and excellent electrical insulation. Its most common applications include high-performance bearings, chemical-resistant seals and gaskets, electrical housings, and components for medical and food processing equipment where purity and inertness are critical.

The core reason for machining PTFE is to create custom parts that leverage its unique properties. While its softness and thermal expansion present challenges, CNC machining provides the necessary precision to control these factors and produce reliable, high-tolerance components.

Why PTFE is a Top Choice for Specific Applications

The selection of PTFE is almost always driven by its exceptional material properties. It solves problems that other plastics and metals cannot, particularly in harsh environments.

For Low-Friction and Wear Resistance

PTFE has one of the lowest coefficients of friction of any solid material, making it ideal for parts that slide against each other. It is often described as self-lubricating.

Common parts include bearings, bushings, sliding pads, and wear strips. These components reduce wear on mating surfaces and often eliminate the need for external lubrication.

For Chemical Inertness and Sealing

PTFE is virtually inert and resistant to almost all industrial chemicals and solvents. This makes it a critical material for sealing and fluid handling.

Typical applications are seals, gaskets, valves, and stem packing used in chemical processing, pharmaceutical manufacturing, and laboratory instrumentation.

For Electrical Insulation

With its high dielectric strength and performance over a wide range of frequencies, PTFE is an outstanding electrical insulator.

It is frequently machined into electrical housings, insulators, and cable insulation, especially for high-performance telecommunications and aerospace applications.

For Medical and Food-Grade Components

Virgin PTFE is biocompatible and meets FDA requirements for food contact, making it safe for sensitive applications.

Its hygienic, frictionless surface is perfect for medical equipment components, lab instruments, and parts for food processing machinery that require both purity and smooth movement.

Understanding the Machining Challenges

While its properties make PTFE highly desirable, they also create specific challenges during the CNC machining process. Understanding these is key to producing successful parts.

High Thermal Expansion

PTFE expands and contracts significantly with temperature changes. Heat generated during cutting can easily cause the part to go out of tolerance.

Machinists must use low cutting speeds and feed rates along with sharp tools to minimize heat buildup and maintain dimensional accuracy.

Softness and Deformation

PTFE is a relatively soft material that can be easily compressed or deformed.

This requires low clamping pressure in fixtures to avoid distorting the workpiece. It also means tools must be extremely sharp to shear the material cleanly rather than pushing it.

Specialized Tooling and Finishing

Using the right tools is non-negotiable. Carbide tools with highly polished surfaces and sharp cutting edges are necessary to achieve a clean cut and good surface finish.

Due to its softness, PTFE can produce burrs instead of clean chips, often requiring specific finishing techniques like shot peening to achieve the final desired surface quality.

Virgin vs. Filled PTFE: Key Trade-offs

Not all PTFE is the same. Additives can be blended into the material to enhance specific properties for more demanding roles.

Virgin PTFE: Purity and Compliance

This is pure, unfilled PTFE. Its primary advantages are its extreme chemical resistance and compliance with food-grade and medical standards. It is the top choice when purity is the main concern.

Filled PTFE: Enhanced Mechanical Properties

Materials like glass, carbon, or bronze can be added to PTFE to improve its characteristics. Filled grades offer significantly increased strength, wear resistance, and thermal conductivity, making them suitable for high-load bearings or parts used in aerospace.

Making the Right Choice for Your Application

Selecting the correct grade of PTFE and understanding its machining needs are critical for project success.

- If your primary focus is high purity or biocompatibility: Choose virgin PTFE for any medical, laboratory, or food-grade components.

- If your primary focus is wear resistance and structural strength: Opt for a filled grade of PTFE, such as glass-filled for wear or carbon-filled for strength and conductivity.

- If your primary focus is electrical insulation: Virgin PTFE is the standard due to its excellent and reliable dielectric properties.

- If your primary focus is low-friction movement under load: Filled PTFE grades typically offer better performance for demanding bearings and sliding applications.

By aligning the unique properties of PTFE with the precision of CNC machining, you can engineer components that perform reliably in the most challenging environments.

Summary Table:

| Application Category | Key PTFE Properties | Common CNC Machined Parts |

|---|---|---|

| Low-Friction & Wear | Self-lubricating, low coefficient of friction | Bearings, bushings, sliding pads, wear strips |

| Chemical Resistance | Inert to most chemicals and solvents | Seals, gaskets, valves, stem packing |

| Electrical Insulation | High dielectric strength | Electrical housings, insulators, cable insulation |

| Medical & Food Grade | Biocompatible, FDA compliant, high purity | Medical device components, lab instruments, food machinery parts |

Need a custom PTFE component that meets your exact specifications?

At KINTEK, we specialize in the precision CNC machining of PTFE components—from seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your parts leverage PTFE's unique properties while overcoming its machining challenges, guaranteeing reliability in the most demanding environments.

Whether you require a prototype or a high-volume order, we deliver the precision and performance your application demands.

Contact KINTEK today to discuss your project and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support