In short, PTFE rotary seals are specified for demanding applications where traditional seals fail. They are commonly found in high-performance equipment such as compressors, motors, gearboxes, pumps, and rotary unions across a wide range of critical industries. Their use is prevalent in aerospace, oil and gas, food processing, and pharmaceutical manufacturing due to their unique material properties.

The core reason for choosing a PTFE rotary seal is its resilience. Its unique combination of chemical inertness, wide temperature tolerance, and low-friction performance makes it the default solution for environments that are too fast, too hot, too cold, or too corrosive for standard elastomeric seals.

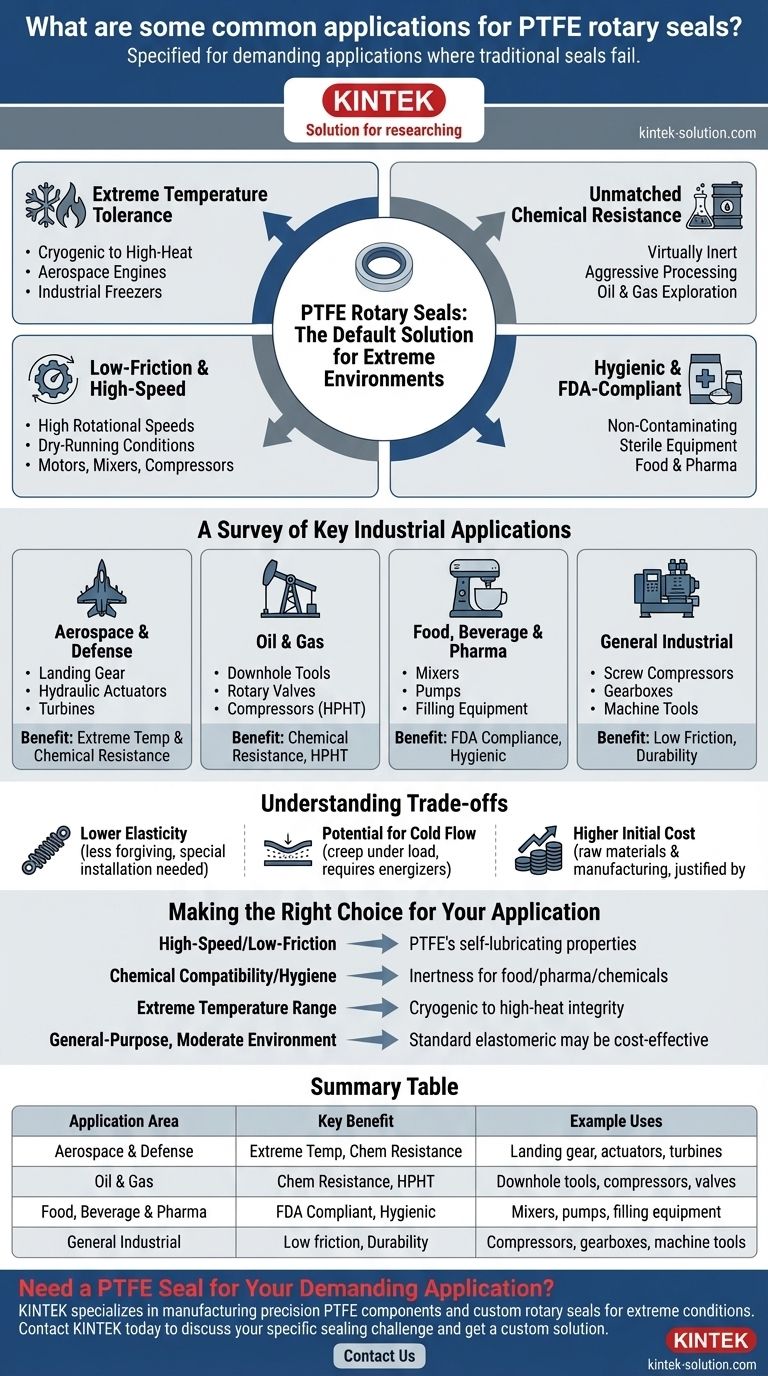

The Core Strengths Driving Adoption

Before listing specific applications, it's essential to understand why PTFE is so frequently chosen. The material's inherent properties solve specific engineering challenges that other materials cannot.

Extreme Temperature Tolerance

PTFE seals maintain their integrity and performance in both cryogenic conditions and high-heat environments. This makes them indispensable in applications ranging from aerospace engine systems to industrial freezers, where traditional rubber seals would become brittle or degrade.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals and solvents. This exceptional resistance allows these seals to be used in aggressive chemical processing, pharmaceutical manufacturing, and oil and gas exploration where they are exposed to corrosive media.

Low-Friction and High-Speed Capability

The material has an extremely low coefficient of friction, which minimizes heat generation and wear. This allows PTFE seals to operate at higher rotational speeds and in dry-running conditions that would destroy a conventional rubber lip seal. This is critical in high-speed motors, mixers, and compressors.

Hygienic and FDA-Compliant Properties

Special grades of PTFE are compliant with FDA regulations, making them safe for direct contact with food and pharmaceutical products. Their non-contaminating nature is essential for sterile equipment like mixers, pumps, and filling machines.

A Survey of Key Industrial Applications

The unique strengths of PTFE seals have led to their widespread adoption in industries where reliability and performance are non-negotiable.

Aerospace and Defense

In this sector, equipment must perform flawlessly under extreme conditions. PTFE seals are found in landing gear systems, hydraulic actuators, turbines, pumps, and engines where they must withstand wide temperature swings and aggressive hydraulic fluids.

Oil and Gas

The harsh environments of energy exploration demand robust sealing solutions. PTFE seals are critical in downhole tools, rotary valves, and compressors, especially in High-Pressure High-Temperature (HPHT) applications where they resist corrosive materials and extreme pressure.

Food, Beverage, and Pharmaceutical

Cleanliness and non-contamination are paramount in these industries. PTFE seals are used extensively in mixers, pumps, and filling equipment because they are easy to clean, do not impart taste or odor, and meet strict regulatory standards for sterile processes.

Heavy-Duty and General Industrial

The durability and wear resistance of PTFE make it ideal for demanding industrial machinery. Applications include screw compressors, gearboxes, machine tools, blowers, and construction equipment like excavators, where seals must endure long service lives under heavy loads.

Understanding the Trade-offs

While highly capable, PTFE seals are not a universal solution. Understanding their limitations is key to proper application.

Lower Elasticity

Compared to rubber, PTFE is a much more rigid material. This means it is less forgiving of imperfections in the shaft or housing and can be more challenging to install without special tools or techniques.

Potential for Cold Flow

PTFE has a tendency to "creep" or deform over time when subjected to a constant high load. In seal design, this is managed with specialized fillers and energizers (like springs), but it remains a consideration for high-pressure static applications.

Higher Initial Cost

The raw materials and manufacturing process for high-performance PTFE seals typically result in a higher upfront cost than for standard elastomeric seals. This cost is justified by their extended service life and reliability in demanding conditions.

Making the Right Choice for Your Application

Selecting the correct seal requires matching its capabilities to your primary operational challenge.

- If your primary focus is high-speed rotation or low friction: PTFE's self-lubricating properties make it ideal for motors and compressors where minimizing heat buildup is critical.

- If your primary focus is chemical compatibility or hygiene: The inertness of PTFE is non-negotiable for food, pharmaceutical, and aggressive chemical processing applications.

- If your primary focus is an extreme temperature range: From cryogenic systems to high-heat engines, PTFE maintains its sealing integrity where rubber-based seals would certainly fail.

- If your primary focus is general-purpose sealing in a moderate environment: A standard elastomeric (rubber) lip seal may be a more cost-effective and forgiving solution for your needs.

By understanding these core strengths and trade-offs, you can confidently specify PTFE seals for applications that demand the highest levels of performance and reliability.

Summary Table:

| Application Area | Key Benefit | Example Uses |

|---|---|---|

| Aerospace & Defense | Extreme temperature tolerance, chemical resistance | Landing gear, hydraulic actuators, turbines |

| Oil & Gas | Chemical resistance, HPHT capability | Downhole tools, compressors, rotary valves |

| Food, Beverage & Pharma | FDA compliance, hygienic, non-contaminating | Mixers, pumps, filling equipment |

| General Industrial | Low friction, high-speed capability, durability | Screw compressors, gearboxes, machine tools |

Need a PTFE Seal for Your Demanding Application?

PTFE seals are the go-to solution for extreme temperatures, aggressive chemicals, high speeds, and sterile environments. If your equipment in the semiconductor, medical, laboratory, or industrial sector is pushing the limits of standard seals, KINTEK can help.

We specialize in manufacturing precision PTFE components, including custom rotary seals. From prototyping to high-volume production, we deliver the reliability and performance your critical applications require.

Contact KINTEL today to discuss your specific sealing challenge and get a custom solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance