At its core, hard PTFE is specified for demanding mechanical applications. These specialized grades are most commonly used for components like high-load bearings, bushings, dynamic seals, valve seats, and gaskets where standard PTFE would deform or wear out too quickly. Their selection is driven by a need for exceptional wear resistance, high compressive strength, and reliable dimensional stability under stress.

The key takeaway is that "hard PTFE" refers to PTFE compounds enhanced with fillers. These fillers fundamentally improve the material's mechanical properties, making it suitable for structural and dynamic roles where virgin PTFE would fail due to its inherent softness and tendency to creep under load.

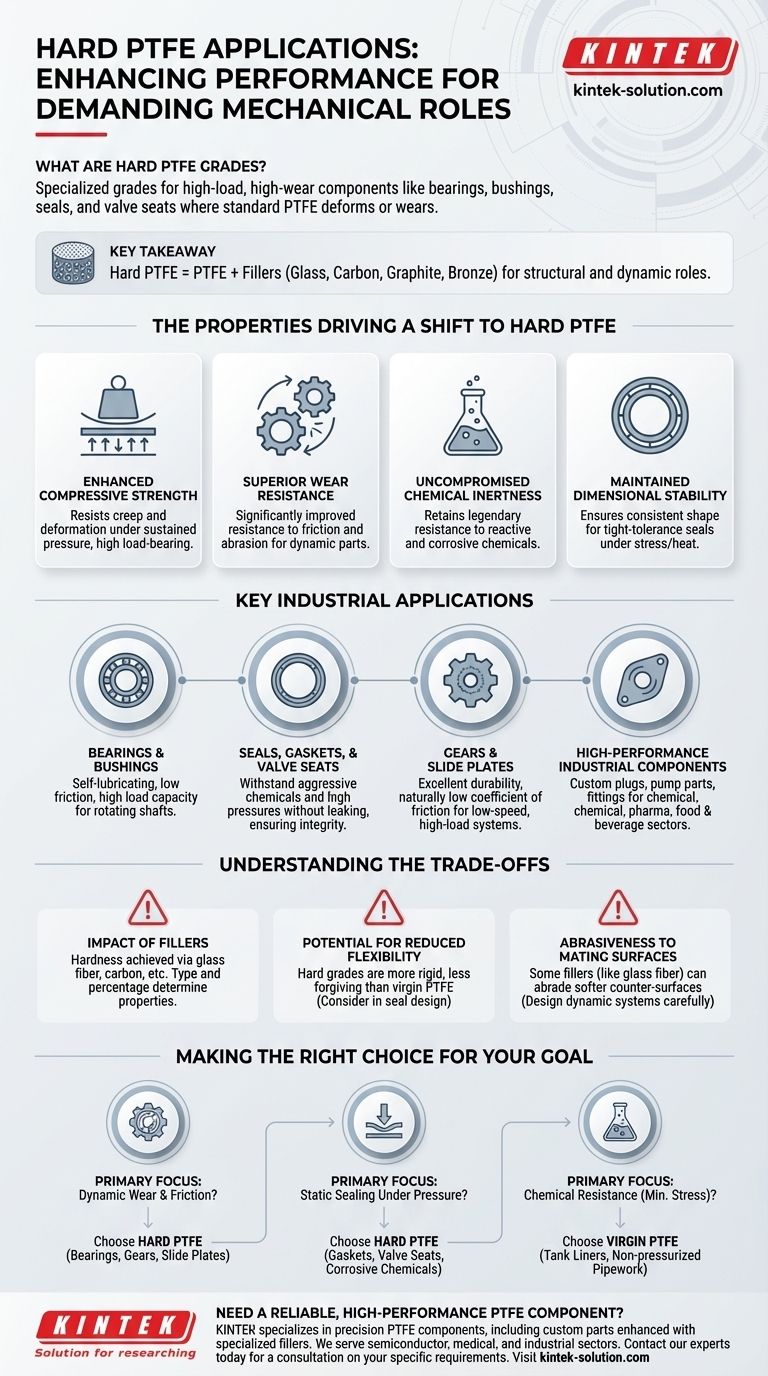

The Properties Driving a Shift to Hard PTFE

Standard, or virgin, PTFE is renowned for its chemical inertness and low friction. However, it is mechanically weak. Hard PTFE grades address these weaknesses directly, expanding the material's utility into engineering applications.

Enhanced Compressive Strength

Standard PTFE can deform under sustained pressure, a phenomenon known as "creep."

Adding fillers dramatically increases the material's ability to resist compression, making it a reliable choice for components that must bear significant loads without changing shape.

Superior Wear Resistance

In applications with moving parts, such as seals or gears, pure PTFE can abrade quickly.

Hard grades offer significantly improved resistance to friction and wear, leading to a much longer service life for dynamic components like slide plates and bearings.

Uncompromised Chemical Inertness

A primary advantage of hard PTFE is that it gains mechanical strength without sacrificing the material's legendary resistance to reactive and corrosive chemicals.

This makes it invaluable for parts like valve seats, seals, and pump components used in chemical processing plants.

Maintained Dimensional Stability

For tight-tolerance parts like gaskets and seals, maintaining a precise shape is critical.

Hard PTFE grades are less susceptible to thermal expansion and deformation under load, ensuring a consistent and reliable seal over a wide range of conditions.

Key Industrial Applications in Detail

The enhanced properties of hard PTFE grades make them the go-to solution in several critical industrial areas where performance and reliability are non-negotiable.

Bearings and Bushings

In mechanical systems, hard PTFE is used to create self-lubricating bearings and bushings. These components support rotating shafts and moving parts, providing low friction and high load-bearing capacity without requiring external lubrication.

Seals, Gaskets, and Valve Seats

This is one of the most common uses for hard PTFE. Its combination of chemical resistance and structural integrity makes it ideal for creating seals and valve seats that must withstand aggressive chemicals and high pressures without leaking or degrading.

This application dates back to the earliest uses of PTFE, where it was vital for handling highly corrosive materials in the Manhattan Project.

Gears and Slide Plates

For low-speed, high-load mechanical systems, gears and slide plates made from hard PTFE offer excellent durability and a naturally low coefficient of friction. This reduces energy consumption and eliminates the need for messy lubricants.

High-Performance Industrial Components

Hard PTFE is frequently machined into custom components for industrial equipment. This includes plugs, pump parts, and fittings used in the chemical, pharmaceutical, and food and beverage industries where both mechanical durability and purity are required.

Understanding the Trade-offs

While hard PTFE grades offer significant advantages, they are not a universal solution. The choice to use a filled grade introduces important design considerations.

The Impact of Fillers

"Hardness" in PTFE is achieved by adding filler materials like glass fiber, carbon, graphite, or bronze to the virgin polymer. The type and percentage of filler determine the final properties of the compound.

Potential for Reduced Flexibility

Increasing hardness and compressive strength often comes at the cost of flexibility. Hard PTFE grades are typically more rigid and less forgiving than their virgin counterparts, which can be a factor in seal design.

Abrasiveness to Mating Surfaces

Some fillers, particularly glass fiber, can be abrasive to softer counter-surfaces like aluminum or unhardened steel. This is a critical consideration in the design of dynamic systems to prevent premature wear on other components.

Making the Right Choice for Your Goal

Selecting the correct material requires a clear understanding of the primary challenge you are trying to solve.

- If your primary focus is dynamic wear and friction: Choose a hard PTFE grade for applications like bearings, gears, and slide plates where parts are in constant motion under load.

- If your primary focus is static sealing under pressure: Use a hard grade for gaskets and valve seats, especially when dealing with corrosive chemicals or high temperatures that demand dimensional stability.

- If your primary focus is chemical resistance with minimal mechanical stress: Virgin PTFE is often sufficient for applications like tank liners or pipework for non-pressurized, corrosive fluids.

Ultimately, hard PTFE grades extend the capabilities of a remarkable polymer into the realm of high-performance engineering challenges.

Summary Table:

| Key Property | Standard PTFE Limitation | Hard PTFE Advantage | Common Application |

|---|---|---|---|

| Compressive Strength | Prone to creep and deformation under load | High load-bearing capacity, resists deformation | Bushings, heavy-duty gaskets |

| Wear Resistance | Wears quickly in dynamic applications | Excellent resistance to friction and abrasion | Bearings, gears, slide plates |

| Dimensional Stability | Can deform under stress or temperature changes | Maintains precise shape under pressure and heat | Valve seats, high-precision seals |

| Chemical Inertness | Excellent chemical resistance | Maintains full chemical resistance with added strength | Seals and components for corrosive chemical processing |

Need a reliable, high-performance PTFE component for your demanding application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, labware, and custom parts—enhanced with specialized fillers for superior mechanical properties. We serve the semiconductor, medical, laboratory, and industrial sectors with custom fabrication from prototypes to high-volume orders.

Let us help you solve your high-load, high-wear engineering challenges with a material solution that offers exceptional durability and chemical resistance. Contact our experts today for a consultation on your specific requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech