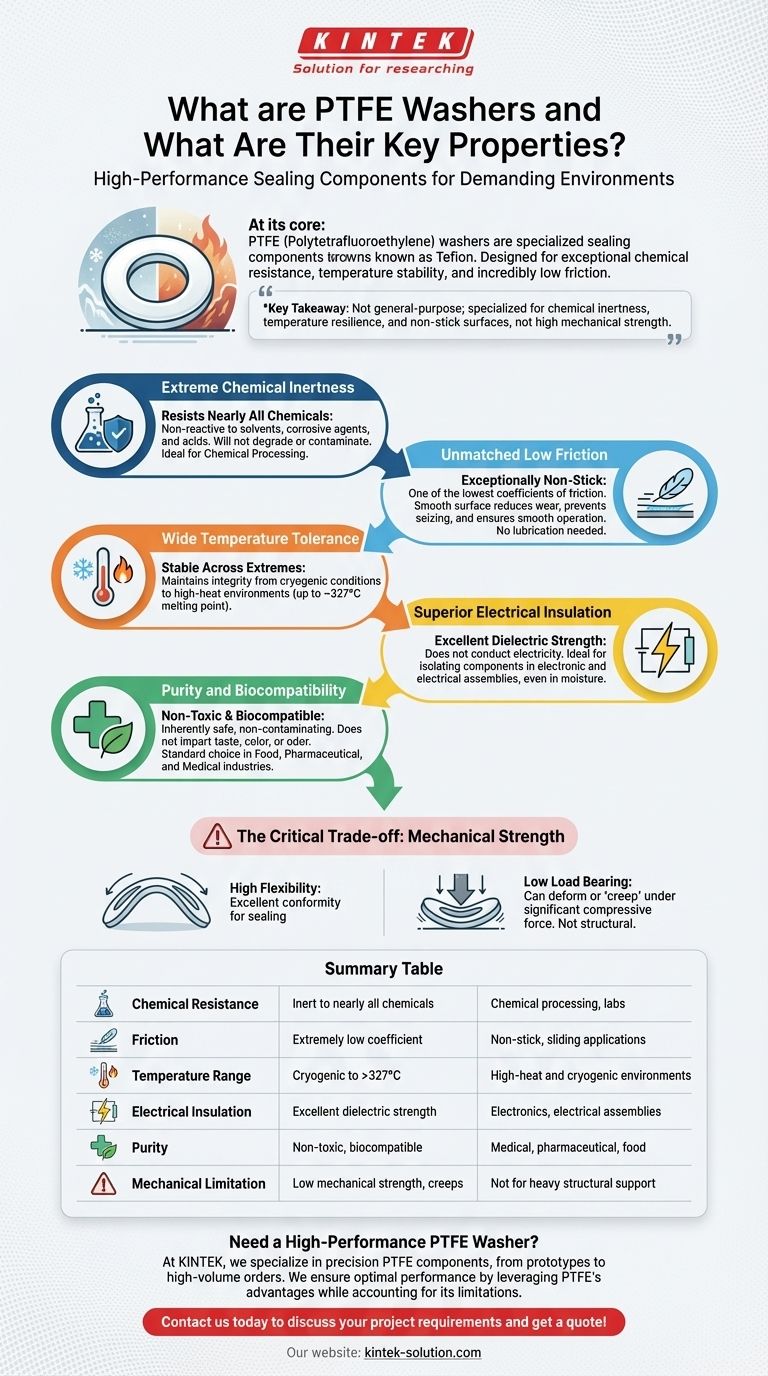

At its core, a PTFE washer is a high-performance sealing component made from Polytetrafluoroethylene, a synthetic fluoropolymer most people know by the brand name Teflon. These washers are engineered for demanding environments where their exceptional chemical resistance, stability across extreme temperatures, and incredibly low friction are required.

The essential takeaway is that PTFE washers are not general-purpose components; they are specialized solutions for environments where chemical inertness, temperature resilience, and non-stick surfaces are more critical than high mechanical strength.

The Defining Properties of PTFE

To understand if a PTFE washer is the right component for your project, you must first understand the unique characteristics of the material itself. These properties work in combination to make it suitable for highly specialized applications.

Extreme Chemical Inertness

PTFE is famous for its resistance to nearly all chemicals, solvents, and corrosive agents. This non-reactive nature means it will not degrade or contaminate the system it is placed in.

This makes it an indispensable material in chemical processing, where it provides reliable sealing in the presence of aggressive substances.

Unmatched Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. Its surface is exceptionally non-stick and smooth.

This property is critical in applications involving moving parts, as it reduces wear, prevents seizing, and ensures smooth operation without the need for lubrication.

Wide Temperature Tolerance

This material demonstrates remarkable stability across a vast range of temperatures. It maintains its integrity and properties in both cryogenic conditions and high-heat environments.

PTFE has a very high melting point, around 327°C, ensuring it performs reliably where other polymers would fail.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with high dielectric strength. It does not conduct electricity, making it ideal for isolating components in electronic and electrical assemblies.

Its performance as an insulator remains stable even when exposed to moisture and high temperatures.

Purity and Biocompatibility

The material is inherently non-toxic, non-contaminating, and biocompatible. It does not impart taste, color, or odor.

These characteristics make PTFE washers a standard choice in the food, pharmaceutical, and medical industries, where purity is a strict requirement.

The Critical Trade-off: Mechanical Strength

While its chemical and thermal properties are exceptional, PTFE's primary limitation lies in its mechanical performance. Understanding this trade-off is crucial for proper application.

High Flexibility vs. Load Bearing

PTFE is a relatively soft and highly flexible material. While this gives it excellent conformity for sealing applications, it also means it can be damaged by heavy loads.

It is not designed to be a structural, load-bearing component. Under significant and sustained compressive force, a PTFE washer can deform or "creep," compromising the integrity of the joint.

Making the Right Choice for Your Application

Use these guidelines to determine if a PTFE washer fits your specific goal.

- If your primary focus is chemical resistance: PTFE is an industry-standard choice for sealing against aggressive acids, bases, and solvents.

- If your primary focus is low-friction movement: Its non-stick surface is ideal for sliding applications or preventing bolts from seizing.

- If your primary focus is high-load structural support: You must consider a stronger material, as PTFE's softness makes it unsuitable for heavy compressive loads.

- If your primary focus is purity for food or medical use: PTFE's non-toxic and biocompatible nature makes it a safe and reliable choice.

By understanding these core properties and limitations, you can deploy PTFE washers with precision and confidence in the applications where they truly excel.

Summary Table:

| Property | Key Characteristic | Ideal For |

|---|---|---|

| Chemical Resistance | Inert to nearly all chemicals and solvents | Chemical processing, labs |

| Friction | Extremely low coefficient of friction | Non-stick, sliding applications |

| Temperature Range | Stable from cryogenic to over 327°C | High-heat and cryogenic environments |

| Electrical Insulation | Excellent dielectric strength | Electronics, electrical assemblies |

| Purity | Non-toxic, biocompatible | Medical, pharmaceutical, food industries |

| Mechanical Limitation | Low mechanical strength, can creep under load | Not for heavy structural support |

Need a high-performance PTFE washer for your specific application?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom washers, seals, and liners. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we can fabricate the exact part you need—from prototypes to high-volume orders.

Our expertise ensures you get a component that leverages PTFE's full advantages while accounting for its limitations, guaranteeing optimal performance in your most demanding environments.

Contact us today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers