At its core, a PTFE slide bearing is a specialized structural component designed to create a low-friction surface that allows large structural elements to move relative to one another. Their primary function in construction is to safely accommodate inevitable movements—such as thermal expansion, contraction, and seismic shifts—preventing the buildup of destructive stress within the structure.

The fundamental challenge in large-scale construction is that structures are not static; they must be designed to move. PTFE slide bearings solve this problem by providing a controlled plane of movement, absorbing forces that would otherwise damage foundations, supports, and primary structural members.

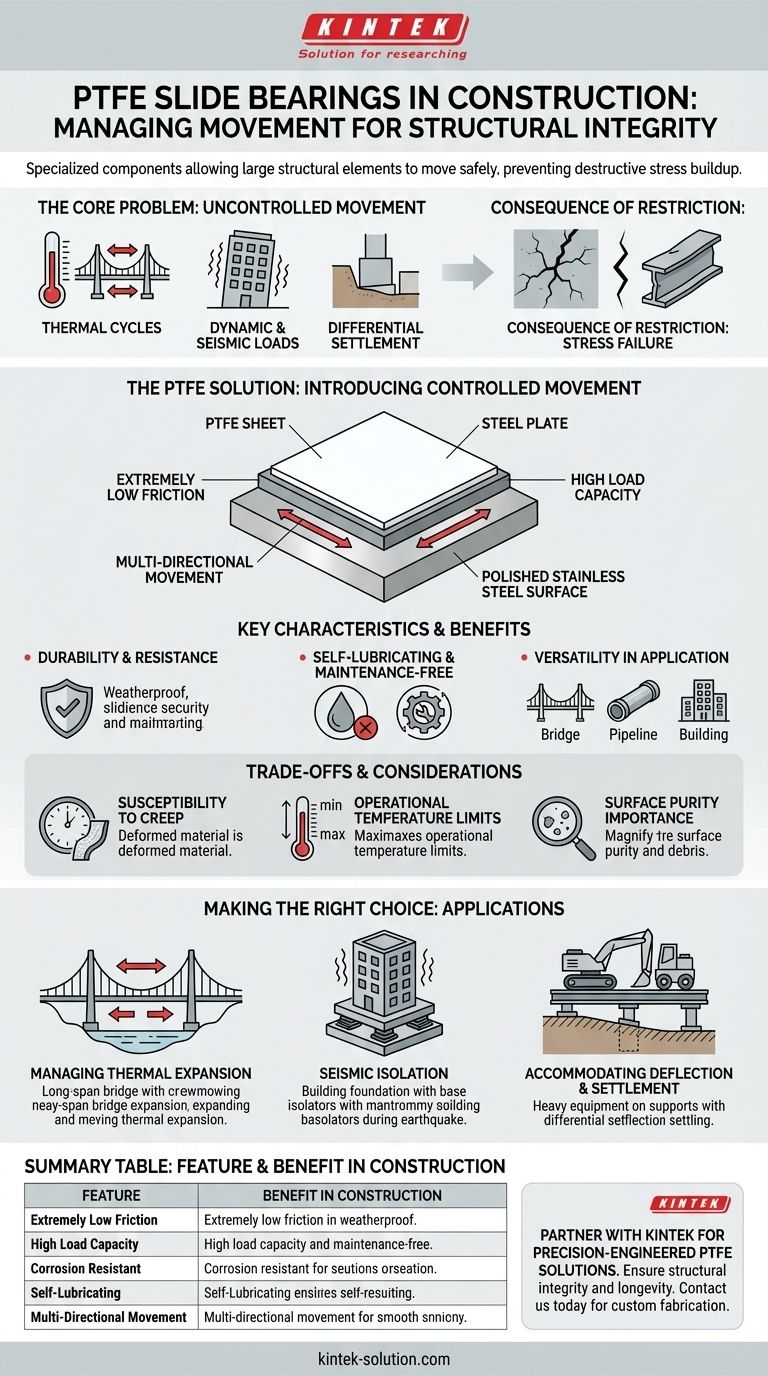

The Core Problem: Uncontrolled Structural Movement

Large structures are in a constant state of subtle motion. Without a mechanism to manage this movement, internal stresses can accumulate to the point of structural failure.

The Inevitability of Thermal Cycles

All construction materials expand when heated and contract when cooled. Over the daily and seasonal temperature cycles, a long bridge or large roof can change in length by several inches, creating immense internal forces.

Dynamic and Differential Loads

Beyond temperature, structures must respond to other forces. This includes seismic shifts, wind loads, and differential settlement, where different parts of a foundation settle into the ground at slightly different rates.

The Consequence of Restriction

If these movements are rigidly restricted, the resulting stress is transferred directly into beams, columns, and foundations. This can lead to concrete cracking, steel deformation, and a compromised service life for the asset.

How PTFE Slide Bearings Provide the Solution

PTFE (Polytetrafluoroethylene) slide bearings introduce a simple and highly effective mechanical release system at key points within a structure.

The Power of Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This property allows massive structural elements, weighing many tons, to slide past each other with minimal resistance.

Accommodating Multi-Directional Movement

A typical slide bearing consists of a PTFE sheet bonded to a steel plate, which slides against another surface (often polished stainless steel). This assembly allows for smooth, controlled movement in any horizontal direction.

High Load Capacity

Despite their low friction, these bearing systems are engineered to withstand enormous compressive loads. This allows them to support primary structural elements like bridge girders or roof trusses while still permitting movement.

Key Characteristics and Benefits

The unique properties of PTFE make it an ideal material for this critical structural role.

Durability and Resistance

PTFE is virtually immune to chemical corrosion and weathering. This ensures a long, reliable service life even when exposed to harsh environmental conditions.

Self-Lubricating and Maintenance-Free

The material's low-friction nature is inherent, requiring no external lubrication. Once installed correctly, slide bearings are a fit-and-forget component, which is critical for inaccessible locations like bridge piers.

Versatility in Application

This principle is applied across the construction industry. You will find PTFE slide bearings in bridges, large buildings, industrial pipelines, and heavy equipment supports where thermal expansion and other movements must be managed.

Understanding the Trade-offs and Considerations

While highly effective, PTFE slide bearings are not without limitations that engineers must account for in their designs.

Susceptibility to Creep

Under a sustained, heavy load, PTFE can slowly deform over time—a phenomenon known as "creep." This must be calculated and factored into the design to ensure long-term performance.

Operational Temperature Limits

Although resistant to a wide range of temperatures, PTFE does have upper and lower service limits. In extreme environments, these limitations must be respected to prevent material degradation.

Importance of Surface Purity

The effectiveness of a PTFE bearing is highly dependent on the condition of the mating surfaces. The introduction of dirt, grit, or debris can increase friction and score the sliding surface, impairing its function.

Making the Right Choice for Your Goal

Specifying a PTFE slide bearing is about identifying where controlled movement is necessary to ensure structural integrity.

- If your primary focus is managing thermal expansion: Use them at the connection points of long-span bridges, large roof structures, or extensive pipeline runs to prevent stress from temperature cycles.

- If your primary focus is seismic isolation: Incorporate them into a building's foundation system to allow the ground to move during an earthquake while the structure above remains more stable.

- If your primary focus is accommodating deflection and settlement: Place them between a heavy structural element and its support to prevent the transfer of stress as the components move or settle differently under load.

Ultimately, PTFE slide bearings are an elegant engineering solution that allows massive, rigid structures the freedom to move safely.

Summary Table:

| Feature | Benefit in Construction |

|---|---|

| Extremely Low Friction | Allows massive structures to move with minimal resistance |

| High Load Capacity | Supports heavy structural elements like bridge girders |

| Corrosion & Weather Resistant | Ensures long service life in harsh environments |

| Self-Lubricating | Maintenance-free operation, ideal for inaccessible locations |

| Multi-Directional Movement | Accommodates thermal expansion, contraction, and seismic shifts |

Ensure the structural integrity and longevity of your project with precision-engineered PTFE components from KINTEK.

Whether you are designing a long-span bridge, a large-scale building, or an industrial pipeline system, managing structural movement is critical. KINTEK specializes in manufacturing high-performance PTFE seals, liners, and custom components, including slide bearings, for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders to meet your exact specifications. Let our expertise in PTFE solutions help you accommodate thermal expansion and seismic forces safely.

Contact KINTEK today to discuss your project requirements and discover how our PTFE components can bring reliability and durability to your construction applications.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability