In demanding rotary applications, PTFE lip seals are a high-performance sealing solution designed to excel where conventional elastomer (rubber) seals fail. They are engineered from Polytetrafluoroethylene (PTFE), a material known for its extremely low friction, chemical inertness, and ability to withstand high speeds and extreme temperatures, providing enhanced reliability and a longer service life in challenging operating conditions.

PTFE lip seals are not a direct replacement for all standard seals; they are a specialized solution engineered for high-performance scenarios. Their key advantage lies in the inherent properties of PTFE—extremely low friction and chemical inertness—which enable reliable sealing in conditions that would cause conventional elastomer seals to degrade and fail.

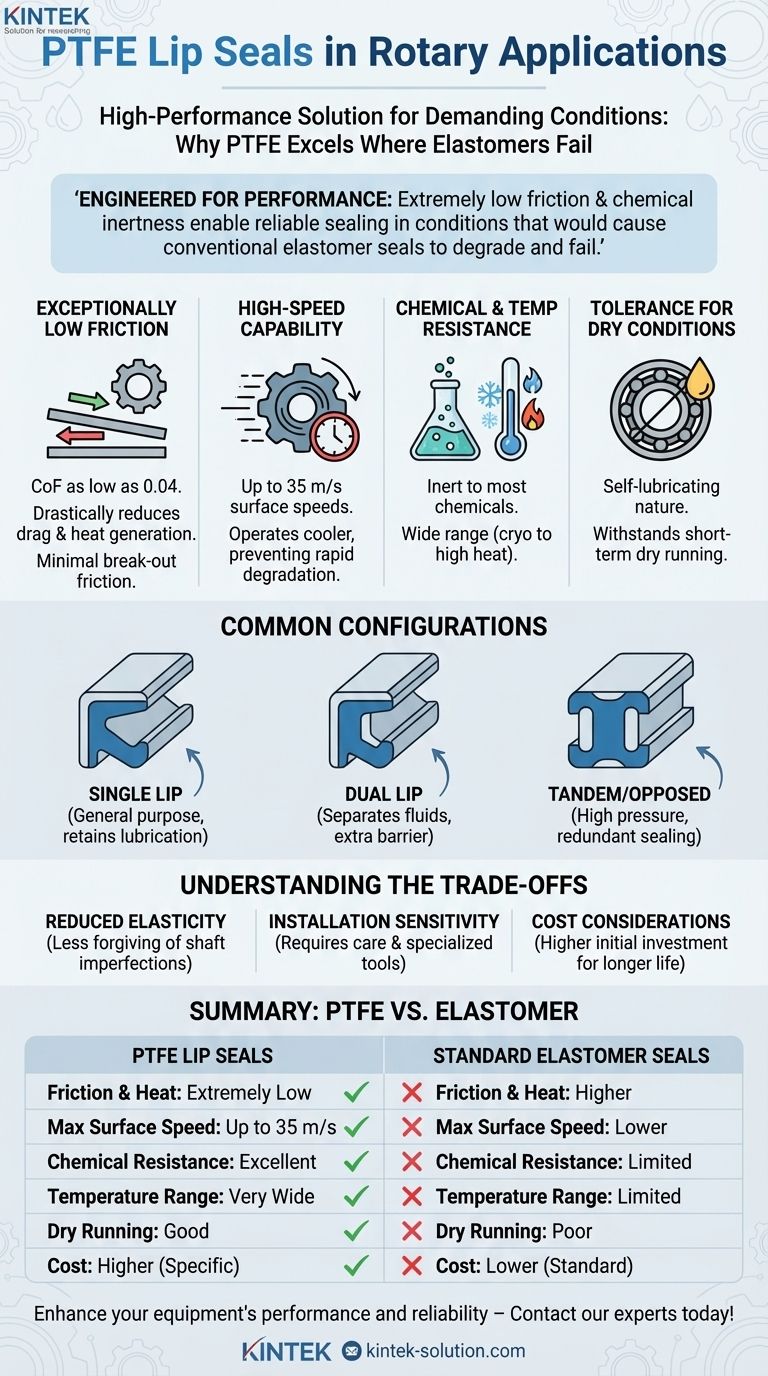

The Core Principle: Why PTFE Excels Where Elastomers Fail

The decision to use a PTFE seal is driven by application demands that exceed the physical limits of traditional rubber-based materials. The fundamental properties of the PTFE material are what give these seals their distinct advantages.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often as low as 0.04. This self-lubricating property drastically reduces drag on the rotating shaft.

This results in lower heat generation and less power consumption, which is critical for maintaining efficiency and preventing premature seal failure. It also ensures minimal break-out friction, meaning the force required to start movement after a long standstill is very low.

High-Speed Capability

Because PTFE seals generate significantly less heat, they can operate at much higher rotational speeds than elastomer seals. They can maintain performance and integrity at surface speeds of up to 35 m/s.

In contrast, the friction from a standard rubber seal at such speeds would generate enough heat to rapidly degrade the material, leading to leakage and failure.

Chemical and Temperature Resistance

PTFE is virtually inert to most industrial chemicals and solvents. This makes it the ideal choice for sealing in corrosive environments where aggressive media would attack and break down conventional seal materials.

These seals also operate across a wide temperature spectrum, maintaining their properties in both cryogenic conditions and high-heat applications where elastomers would become brittle or lose their integrity.

Tolerance for Dry and Low-Lubrication Conditions

The self-lubricating nature of PTFE allows these seals to withstand short-term dry running and long-term operation with minimal lubrication.

This is a critical advantage in applications where consistent lubrication cannot be guaranteed, a condition that would cause a standard rubber seal to quickly overheat and fail.

Common Configurations of PTFE Lip Seals

While all are based on the same core material, PTFE seals are available in several designs to meet specific application pressures and sealing requirements.

Single Lip Seals

This is the most common design, suitable for general-purpose sealing in lubricated environments and low-pressure applications. It effectively retains lubrication and prevents the ingress of external contaminants.

Dual Lip Seals

As the name implies, this design features two sealing lips. It can be used to separate two different fluids or to provide an extra barrier against harsh external contamination in dirty or dusty environments.

Tandem and Opposed Lip Designs

These more complex configurations are engineered for higher-pressure scenarios or particularly harsh operating conditions. They provide redundant sealing and are often customized for specific, demanding applications.

Understanding the Trade-offs

While powerful, PTFE seals are not a universal solution. Their unique properties come with practical considerations that must be understood to ensure successful implementation.

Reduced Elasticity

PTFE is a much more rigid material than elastomer. It is less forgiving of shaft imperfections, runout, or significant vibration. A flexible elastomer seal may provide a more reliable seal in applications with these conditions.

Installation Sensitivity

Due to its stiffness, a PTFE lip can be damaged during installation if not handled with care. Specialized installation tools and procedures are often required to ensure the seal is not creased or scratched, which would compromise its performance.

Cost Considerations

As a specialized, high-performance component, PTFE seals are typically more expensive than their standard elastomer counterparts. The higher initial cost is justified by their longer life and reliability in demanding applications.

How to Select the Right Sealing Strategy

Your choice should be based on a clear understanding of your application's specific operating demands.

- If your primary focus is high rotational speed: PTFE's low friction minimizes heat buildup, making it the superior choice for preventing seal failure.

- If your primary focus is chemical compatibility: PTFE's inertness provides unmatched reliability where aggressive fluids would destroy conventional seals.

- If your primary focus is dealing with poor lubrication: The self-lubricating nature of PTFE allows for safe operation in conditions that would cause elastomer seals to fail.

- If your primary focus is a standard, low-cost application: A traditional elastomer seal is often the more practical and cost-effective choice if the operating conditions are not extreme.

Choosing the right seal is about matching the material's core strengths to the specific challenges of your application.

Summary Table:

| Feature | PTFE Lip Seals | Standard Elastomer Seals |

|---|---|---|

| Friction & Heat Generation | Extremely Low | Higher |

| Max Surface Speed | Up to 35 m/s | Lower |

| Chemical Resistance | Excellent (Virtually Inert) | Limited |

| Temperature Range | Very Wide (Cryogenic to High Heat) | Limited |

| Dry Running Capability | Good (Self-Lubricating) | Poor |

| Cost | Higher (Specialized) | Lower (Standard) |

Struggling with seal failure in high-speed, corrosive, or high-temperature applications?

At KINTEK, we specialize in manufacturing precision PTFE components, including lip seals, for the semiconductor, medical, laboratory, and industrial sectors. Our seals are engineered to deliver unmatched reliability and a longer service life in the most demanding conditions.

We offer custom fabrication from prototypes to high-volume orders, ensuring the perfect seal for your specific application challenges.

Enhance your equipment's performance and reliability — Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance