The most common alternative name for a Teflon encapsulated silicone o-ring is a PTFE encapsulated o-ring. Because "Teflon" is a specific brand name for the chemical Polytetrafluoroethylene (PTFE), the terms are often used interchangeably in technical and industrial contexts.

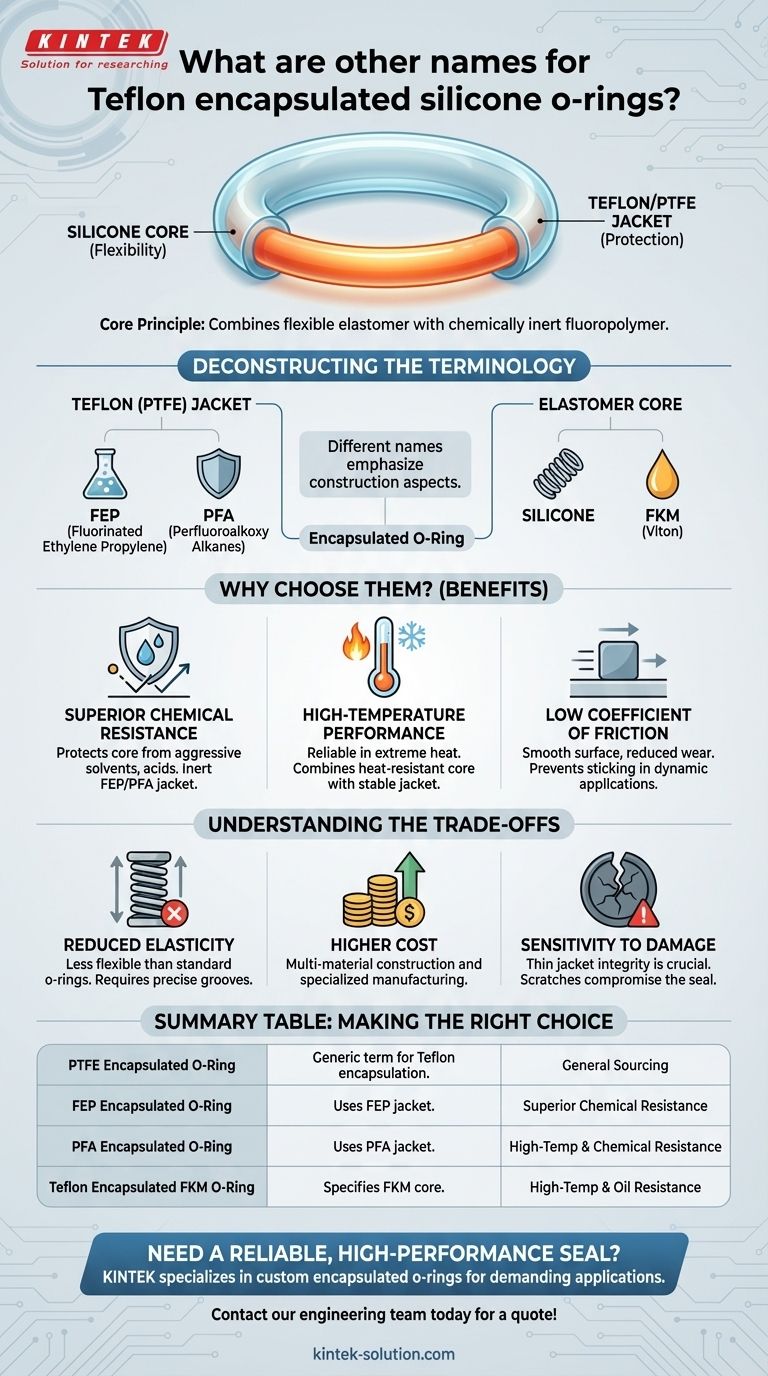

The core principle is combining two materials: a flexible elastomer core like silicone for compressibility and a chemically inert fluoropolymer jacket (like Teflon FEP or PFA) for protection against harsh environments.

Deconstructing the Terminology

Understanding the name of this component requires breaking it down into its constituent parts. The different names simply emphasize different aspects of its construction.

The "Teflon" vs. "PTFE" Jacket

Teflon is the registered trademark for a family of fluoropolymer resins, most famously PTFE. In engineering, it's more precise to refer to the specific material.

The seamless outer jacket is typically made of FEP (Fluorinated Ethylene Propylene) or PFA (Perfluoroalkoxy Alkanes), which are specific types of Teflon resins that can be melt-processed to create the seamless encapsulation.

Therefore, you will see names like FEP encapsulated or PFA encapsulated o-rings when a specific material grade is required.

The Elastomer Core

While your query specified a silicone core, this is not the only option available. The core provides the flexibility and "memory" for the seal.

The two most common core materials are silicone and FKM (often known by the brand name Viton). A part might be generically called an "encapsulated o-ring" without specifying the core material.

Why Choose an Encapsulated O-Ring?

These components are designed to solve a specific problem: sealing applications where a standard elastomeric o-ring would fail due to chemical attack or friction.

Superior Chemical Resistance

The outer FEP or PFA jacket is almost completely chemically inert. This protects the vulnerable inner silicone or FKM core from aggressive solvents, acids, and other chemicals.

High-Temperature Performance

By combining a temperature-resistant core like silicone with a stable Teflon jacket, these o-rings can function reliably in high-temperature industrial and automotive applications.

Low Coefficient of Friction

The Teflon surface is extremely smooth and has a very low friction coefficient. This reduces wear and tear during installation and in dynamic applications, preventing sticking and abrasion.

Understanding the Trade-offs

While highly effective, encapsulated o-rings are not a universal solution. Their unique construction introduces specific limitations.

Reduced Elasticity

The rigid outer jacket significantly reduces the o-ring's flexibility and compressibility compared to a standard, solid elastomer o-ring. This means they require more precise groove designs and may not seal as effectively in non-standard or imperfect hardware.

Higher Cost

The multi-material construction and specialized manufacturing process make encapsulated o-rings more expensive than their single-material counterparts.

Sensitivity to Damage

The protective benefit of the o-ring depends entirely on the integrity of the thin outer jacket. Any scratch or damage during installation can create a leak path, compromising the entire seal.

Making the Right Choice for Your Goal

When searching for or specifying these parts, using the right terminology is key to getting the component you need.

- If your primary focus is general sourcing: Use the terms "Teflon encapsulated o-ring" and "PTFE encapsulated o-ring" to get the widest range of results.

- If your primary focus is chemical compatibility: Specify "FEP encapsulated" or "PFA encapsulated" based on the specific chemicals in your application.

- If your primary focus is temperature range: Ensure you specify the core material, such as "Teflon encapsulated silicone o-ring," as silicone and FKM have different thermal properties.

Knowing these variations ensures you can find and specify the exact high-performance seal your project requires.

Summary Table:

| Term | Description | Common Use Case |

|---|---|---|

| PTFE Encapsulated O-Ring | Generic term for Teflon-type encapsulation. | General sourcing, interchangeable with "Teflon". |

| FEP Encapsulated O-Ring | Uses Fluorinated Ethylene Propylene jacket. | Superior chemical resistance. |

| PFA Encapsulated O-Ring | Uses Perfluoroalkoxy Alkanes jacket. | High-temperature and chemical resistance. |

| Teflon Encapsulated FKM O-Ring | Specifies a Viton® (FKM) core. | High-temperature and oil resistance applications. |

Need a Reliable, High-Performance Seal for a Demanding Application?

KINTEK specializes in manufacturing precision PTFE components, including custom encapsulated o-rings for the semiconductor, medical, laboratory, and industrial sectors. We combine expert material knowledge with precision production to deliver seals that offer superior chemical resistance, high-temperature performance, and low friction.

Whether you need a standard PTFE encapsulated silicone o-ring or a custom solution with a specific FEP or PFA jacket, we can fabricate from prototypes to high-volume orders to meet your exact specifications.

Contact our engineering team today to discuss your application requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials