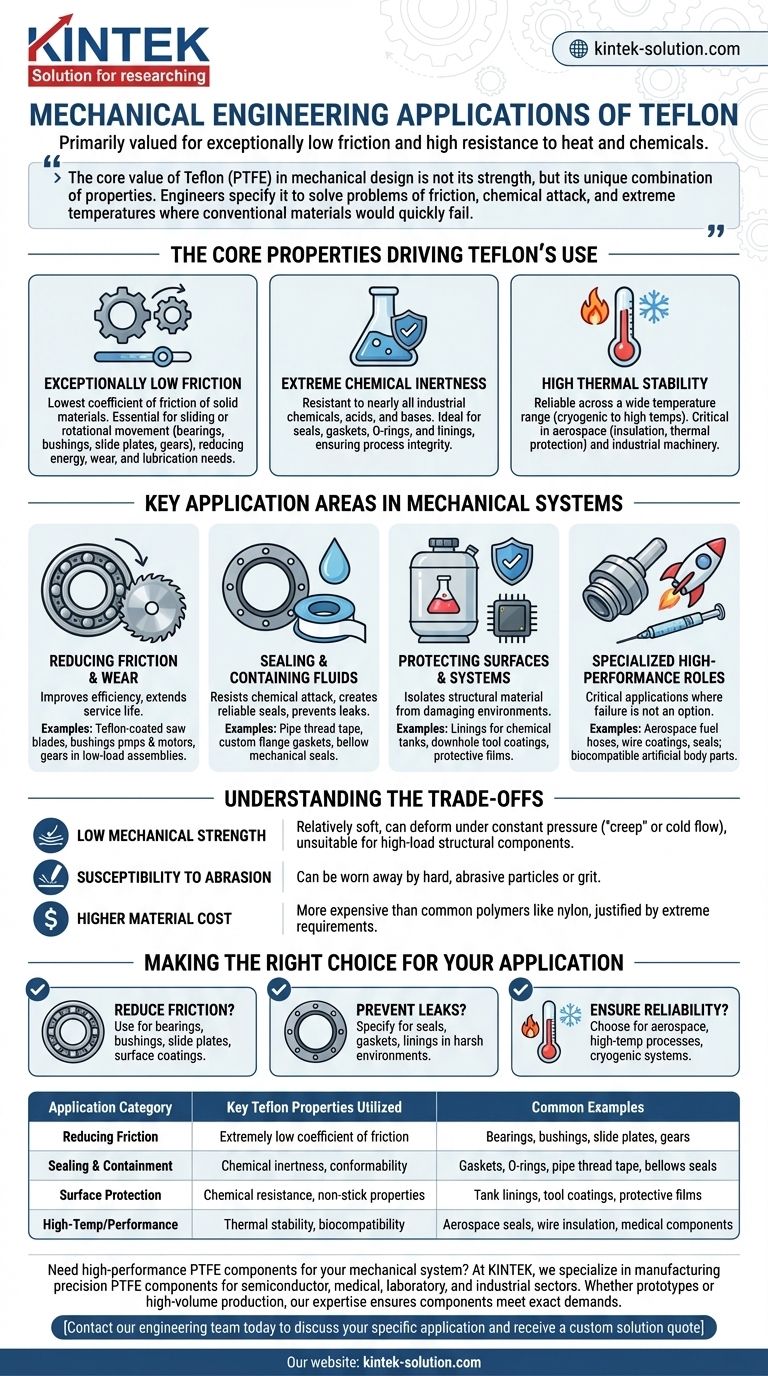

In mechanical engineering, Teflon is primarily valued for its exceptionally low friction and high resistance to heat and chemicals. This makes it a critical material for applications that demand smooth movement, leak-proof sealing, and durability in harsh conditions, including bearings, seals, gears, gaskets, and protective coatings for industrial equipment.

The core value of Teflon (PTFE) in mechanical design is not its strength, but its unique combination of properties. Engineers specify it to solve problems of friction, chemical attack, and extreme temperatures where conventional materials would quickly fail.

The Core Properties Driving Teflon's Use

Teflon, a brand name for Polytetrafluoroethylene (PTFE), is not a single-use material. Its widespread adoption stems from a powerful set of inherent characteristics that solve persistent engineering challenges.

Exceptionally Low Friction

Teflon has one of the lowest coefficients of friction of any known solid material. This "slipperiness" is its most famous attribute.

This property is fundamental for components designed for sliding or rotational movement, such as bearings, bushings, slide plates, and gears. Using Teflon reduces the energy required for movement, minimizes wear, and can often eliminate the need for liquid lubricants.

Extreme Chemical Inertness

Teflon is resistant to nearly all industrial chemicals, acids, and bases. It does not react with the substances it comes into contact with.

This makes it an ideal choice for seals, gaskets, O-rings, and linings for pipes and vessels in the chemical processing, oil and gas, and even biomedical industries. It ensures process integrity and prevents component degradation from corrosion.

High Thermal Stability

Teflon performs reliably across an impressively wide temperature range. It maintains its properties in both cryogenic conditions and at high temperatures where other polymers would melt or become brittle.

This thermal resistance is critical in aerospace applications for wire insulation and thermal protection systems, as well as in industrial machinery where components operate near engines or heated processes.

Key Application Areas in Mechanical Systems

These core properties translate directly into versatile, real-world mechanical applications across numerous industries.

Reducing Friction and Wear

The most common application is creating low-friction interfaces. This improves efficiency and dramatically extends the service life of machinery.

Examples include Teflon-coated saw blades, bushes in pumps and motors, and gears in low-load assemblies. These components operate more smoothly and require significantly less maintenance.

Sealing and Containing Fluids

Teflon’s ability to resist chemical attack while creating a reliable seal is indispensable. It prevents leaks of potentially hazardous or valuable fluids.

This is seen in pipe thread tape, custom-machined gaskets for flanges, and bellow mechanical seals used in pulp and paper manufacturing. These applications rely on Teflon's ability to conform to surfaces and withstand corrosive media.

Protecting Surfaces and Systems

Teflon is often applied as a protective layer or lining. It isolates a structural material, like steel, from a damaging external environment.

Applications include linings for chemical tanks, coatings on downhole tools in oil drilling to reduce wear, and protective films for sensitive electronic components to prevent corrosion.

Specialized High-Performance Roles

In the most demanding fields, Teflon is used for applications where failure is not an option.

In the aerospace sector, it is used for fuel hoses, wire coatings, and critical seals. Because it is biocompatible, its chemical inertness also makes it suitable for creating certain artificial body parts that won't be rejected by the body.

Understanding the Trade-offs

While incredibly useful, Teflon is not a universal solution. An effective engineer must understand its limitations to use it correctly.

Low Mechanical Strength

Teflon is a relatively soft material. It is not suitable for high-load structural components, as it can deform under constant pressure, a phenomenon known as "creep" or cold flow.

Susceptibility to Abrasion

While Teflon has extremely low friction, it can be worn away by hard, abrasive particles. In environments with significant grit or particulate, a harder material may be required.

Higher Material Cost

Compared to common polymers like nylon or polyethylene, PTFE is more expensive. Its use must be justified by the performance requirements of the application, such as extreme temperature or chemical exposure.

Making the Right Choice for Your Application

Selecting Teflon is about matching its unique strengths to a specific engineering problem.

- If your primary focus is reducing friction in moving parts: Use Teflon for bearings, bushings, slide plates, or as a surface coating to minimize energy loss and wear.

- If your primary focus is preventing leaks in harsh environments: Specify Teflon for seals, gaskets, and linings, especially when dealing with corrosive chemicals or high temperatures.

- If your primary focus is ensuring reliability under extreme temperatures: Choose Teflon for components in aerospace, high-temperature industrial processes, or cryogenic systems.

Ultimately, Teflon is the material of choice when you need a component to slide easily, resist aggressive chemicals, and endure extreme temperatures.

Summary Table:

| Application Category | Key Teflon Properties Utilized | Common Examples |

|---|---|---|

| Reducing Friction | Extremely low coefficient of friction | Bearings, bushings, slide plates, gears |

| Sealing & Containment | Chemical inertness, conformability | Gaskets, O-rings, pipe thread tape, bellows seals |

| Surface Protection | Chemical resistance, non-stick properties | Tank linings, tool coatings, protective films |

| High-Temp/Performance | Thermal stability, biocompatibility | Aerospace seals, wire insulation, medical components |

Need high-performance PTFE components for your mechanical system?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, bushings, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume production, our expertise in custom fabrication ensures your components meet the exact demands of friction reduction, chemical resistance, and thermal stability.

Contact our engineering team today to discuss your specific application and receive a custom solution quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs