At its core, a machined PTFE part is made from one thing: 100% Virgin Polytetrafluoroethylene. This material is a high-performance synthetic fluoropolymer, a type of plastic known for its exceptional durability and unique properties, which stem directly from its simple but incredibly robust chemical structure.

The critical takeaway is that PTFE's remarkable performance—its chemical inertness, temperature resistance, and non-stick surface—is not due to a complex mixture of additives. Instead, it originates from the powerful and stable bond between its only two components: carbon and fluorine atoms.

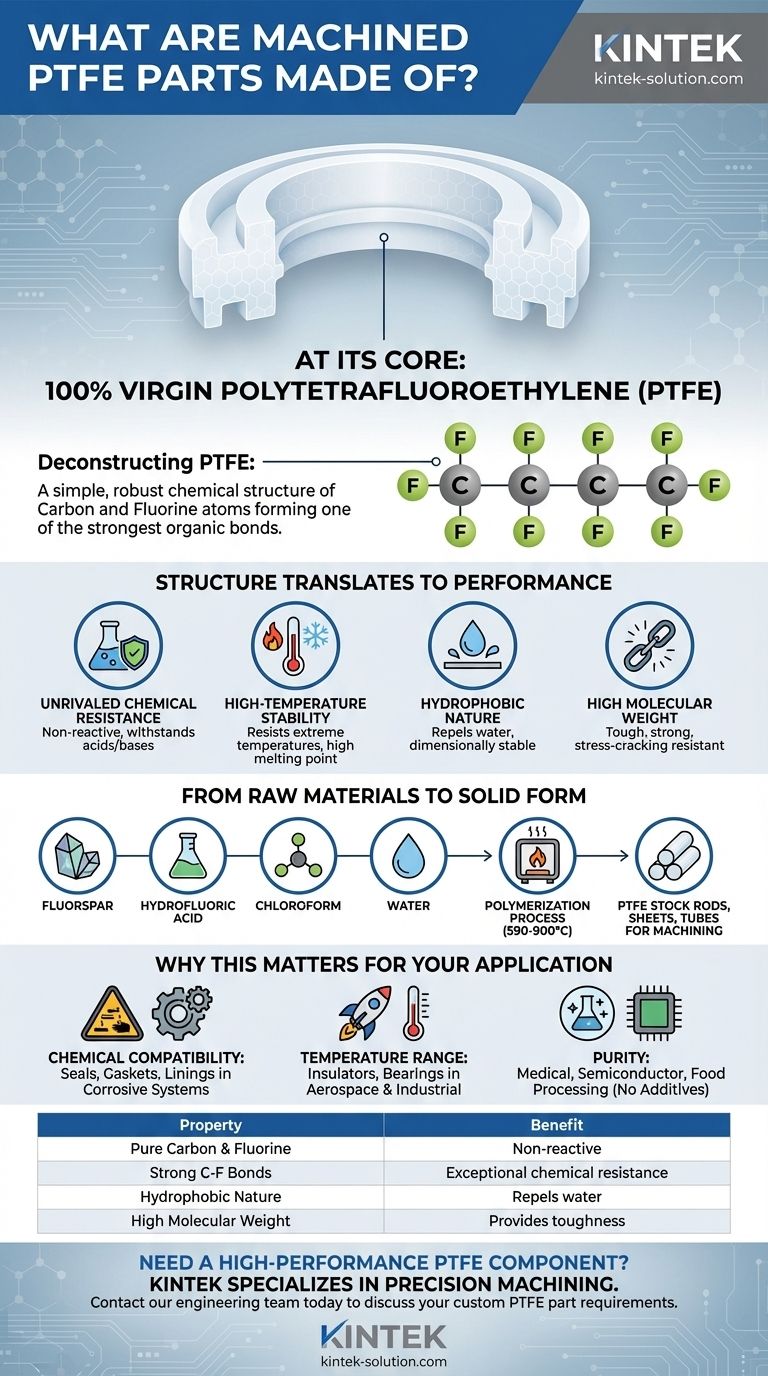

Deconstructing PTFE: The Chemical Foundation

To understand why PTFE is chosen for demanding applications, we must first look at its molecular structure. It's elegantly simple and incredibly effective.

The Core Elements: Carbon and Fluorine

PTFE is a fluorocarbon, a polymer composed exclusively of carbon and fluorine atoms. This purity is fundamental to its predictable and consistent behavior in various environments.

A Chain of Strength

The atoms are arranged in a long, linear chain. A central "spine" of carbon atoms is completely sheathed by a protective layer of fluorine atoms, with each carbon atom bonded to two fluorine atoms.

The Power of the Carbon-Fluorine Bond

This bond is one of the strongest single bonds in organic chemistry. The fluorine atoms create a tight, stable, and non-reactive shield around the carbon chain, effectively protecting it from outside chemical attack.

How Chemical Structure Translates to Performance

The unique molecular makeup of PTFE gives rise to the elite properties that make it so valuable for machined parts.

Unrivaled Chemical Resistance

Because the carbon-fluorine bonds are so strong and stable, PTFE is non-reactive. It can withstand highly corrosive chemicals, acids, and bases, making it ideal for parts used in harsh chemical processing.

High-Temperature Stability

The same powerful bonds that resist chemical attack also resist thermal energy. This gives PTFE a very high melting point and allows it to perform reliably across a wide range of extreme temperatures.

Hydrophobic Nature

As a fluorocarbon, PTFE is hydrophobic, meaning it repels water. It does not absorb moisture, which ensures dimensional stability and consistent electrical properties even in humid conditions.

High Molecular Weight

PTFE is a solid with a very high molecular weight. This contributes directly to its toughness, strength, and resistance to stress-cracking, ensuring the durability of machined components.

From Raw Materials to Solid Form

While the final material is pure carbon and fluorine, its creation involves a precise industrial process.

The Building Blocks

PTFE is synthesized using four primary ingredients: fluorspar, hydrofluoric acid, chloroform, and water.

The Polymerization Process

These raw materials are combined in a chemical reaction chamber and heated to extreme temperatures (between 590-900°C / 1094-1652°F). This process, called polymerization, links the molecules together to form the stable PTFE polymer from which stock rods, sheets, and tubes are made for machining.

Why This Matters for Your Application

Understanding the material's foundation helps you select it with confidence for the right job.

- If your primary focus is chemical compatibility: PTFE's inertness makes it the definitive choice for seals, gaskets, and linings in corrosive or high-purity systems.

- If your primary focus is temperature range: Its thermal stability makes it suitable for insulators, bearings, and components in aerospace or industrial manufacturing.

- If your primary focus is purity: The use of 100% virgin material with no additives is critical for applications in the medical, semiconductor, and food processing industries where contamination cannot be tolerated.

Ultimately, choosing a machined PTFE part means choosing a component defined by the fundamental strength of its chemical bonds.

Summary Table:

| Property | Benefit |

|---|---|

| Pure Carbon & Fluorine | Non-reactive, chemically inert, and predictable performance |

| Strong C-F Bonds | Exceptional chemical resistance and high-temperature stability |

| Hydrophobic Nature | Repels water, ensuring dimensional and electrical stability |

| High Molecular Weight | Provides toughness, strength, and resistance to stress-cracking |

Need a high-performance PTFE component you can trust?

The predictable, high-purity performance of PTFE is critical for success in demanding industries. At KINTEK, we specialize in precision machining of 100% Virgin PTFE into custom seals, liners, labware, and complex components.

We serve the semiconductor, medical, laboratory, and industrial sectors, ensuring every part meets stringent requirements for purity, chemical resistance, and thermal stability. From rapid prototypes to high-volume production, our expertise guarantees a perfect fit for your application.

Contact our engineering team today to discuss your custom PTFE part requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support