To successfully machine Polytetrafluoroethylene (PTFE), you must prioritize sharp tooling for clean cuts, effective cooling to manage thermal expansion, controlled speeds and feeds to prevent material tearing, and minimal clamping pressure to avoid part deformation. These techniques are not merely suggestions; they are essential for counteracting the material's unique softness and thermal sensitivity.

The core challenge of machining PTFE is not its hardness, but its inherent instability. Success depends entirely on managing the material's tendency to deform under pressure and expand with heat, which requires a focus on finesse over force.

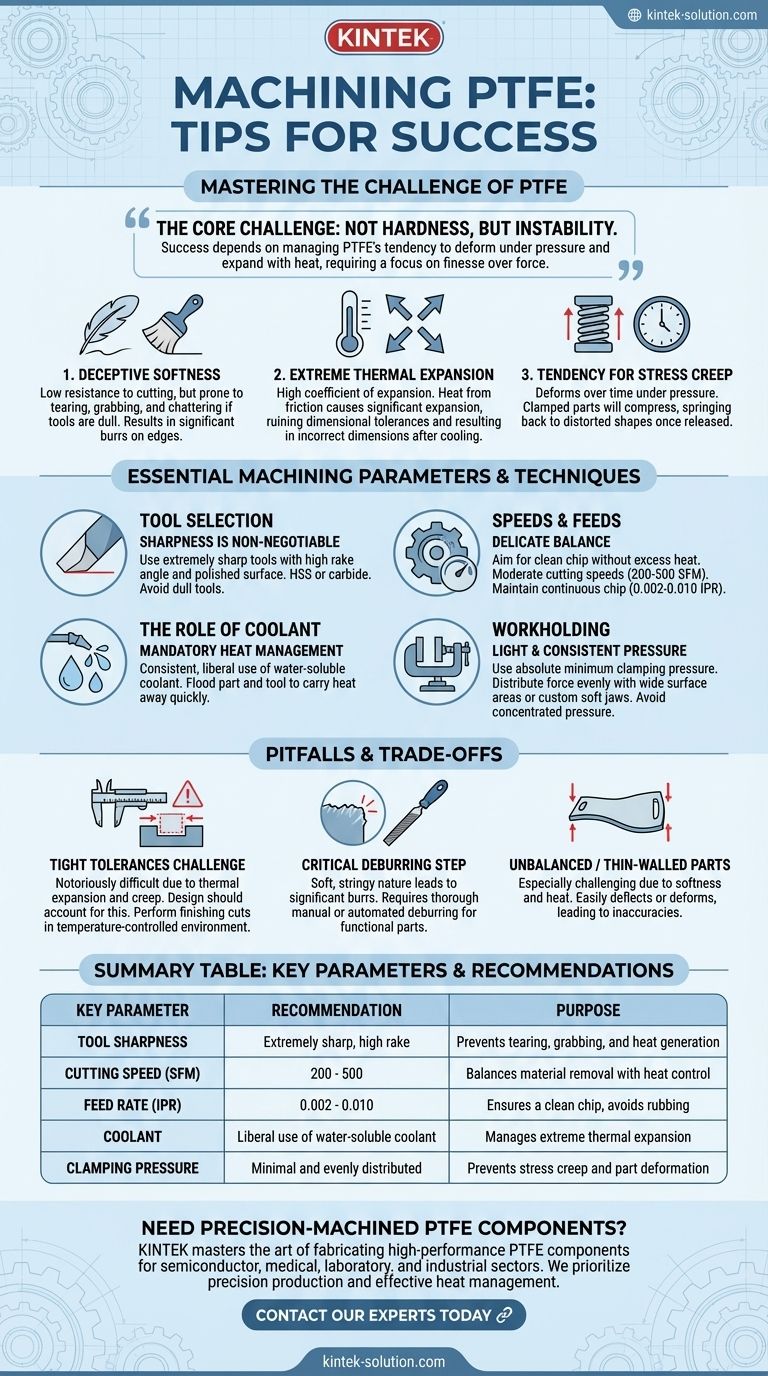

The Core Challenge: Understanding PTFE's Behavior

Machining PTFE is deceptively simple at first glance. It's soft and cuts easily. However, achieving dimensional accuracy requires a deep understanding of its three primary characteristics.

Its Deceptive Softness

PTFE's low density and softness mean it offers little resistance to a cutting tool. While this makes removal easy, it also makes the material prone to tearing, grabbing, and chattering if the tool is not perfectly sharp.

This softness also results in significant burrs forming on part edges, which must be carefully removed in a final deburring step to ensure proper function and assembly.

Extreme Thermal Expansion

PTFE has a very high coefficient of thermal expansion. Even a small amount of heat generated from friction during cutting will cause the material to expand significantly, ruining dimensional tolerances.

Once the part cools, it will contract, and dimensions that seemed correct during the cut will no longer be in spec. This makes heat management the primary battle in precision PTFE machining.

Tendency for Stress Creep

Under pressure, PTFE will deform over time. This property, known as stress creep, is a major challenge for workholding.

If a part is clamped too tightly in a vise or fixture, it will slowly compress. The part may be perfectly machined, but once the clamping pressure is released, it will spring back to a distorted, unusable shape.

Essential Machining Parameters and Techniques

Every machining decision must be made with the goal of mitigating the material's natural tendencies.

Tool Selection: Sharpness is Non-Negotiable

The single most important factor is the cutting tool's edge. Use extremely sharp tools with a high rake angle and a polished, smooth surface.

While High-Speed Steel (HSS) or carbide tools work well, the sharpness and geometry of the cutting edge are far more critical than the tool material itself. A dull tool will plow through the material, generating excessive heat and a poor finish.

Speeds and Feeds: A Delicate Balance

The goal is to produce a clean chip without generating excess heat. Rubbing, rather than cutting, is the primary source of heat and must be avoided.

Start with moderate cutting speeds, typically between 200 to 500 surface feet per minute (SFM).

Use feed rates that are high enough to maintain a continuous chip, generally 0.002 to 0.010 inches per revolution (IPR). A feed rate that is too slow will cause the tool to rub, generating heat and a poor surface finish.

The Role of Coolant

Consistent and liberal use of coolant is mandatory for managing thermal expansion. The goal is to flood the part and tool to carry heat away as quickly as it is generated.

Pressurized air can work for roughing cuts, but a water-soluble coolant is superior for finishing operations and holding tight tolerances.

Workholding: Light and Consistent Pressure

Avoid deformation by using the absolute minimum clamping pressure necessary to hold the part securely.

Use fixtures with wide surface areas or custom soft jaws to distribute the clamping force evenly. Never apply concentrated pressure to a single point, as this will guarantee distortion due to stress creep.

Understanding the Pitfalls and Trade-offs

Ignoring PTFE's unique properties will consistently lead to failed parts. Awareness of common failure modes is key to prevention.

The Challenge of Tight Tolerances

Due to its high thermal expansion and tendency to creep, holding tight tolerances on PTFE is notoriously difficult. Part designs should account for this.

If a design requires extremely tight tolerances, it's crucial to perform finishing cuts in a temperature-controlled environment and allow the material to stabilize before final measurements.

The Final, Critical Step: Deburring

The soft, stringy nature of PTFE means that nearly every machined feature will have a significant burr.

This is not a sign of poor machining but an inherent property of the material. A thorough, careful manual or automated deburring process is a required final step for almost any functional PTFE part.

Unbalanced or Thin-Walled Parts

The combination of softness and heat generation makes machining thin-walled or unbalanced parts especially challenging. The cutting forces and heat can easily cause these features to deflect or deform, leading to inaccuracies.

Making the Right Choice for Your Goal

Your approach should adapt based on the most critical outcome for your specific part.

- If your primary focus is achieving the tightest possible dimensional accuracy: Prioritize aggressive cooling and minimal, evenly distributed clamping pressure above all else.

- If your primary focus is attaining a superior surface finish: Concentrate on using exceptionally sharp, polished tooling and a feed rate optimized to produce a clean chip without rubbing.

- If your primary focus is preventing part deformation: Design fixtures that support the entire workpiece and apply the absolute minimum clamping force required.

Ultimately, machining PTFE successfully means respecting the material's properties rather than fighting against them.

Summary Table:

| Key Parameter | Recommendation | Purpose |

|---|---|---|

| Tool Sharpness | Extremely sharp, high rake angle | Prevents tearing, grabbing, and heat generation |

| Cutting Speed (SFM) | 200 - 500 | Balances material removal with heat control |

| Feed Rate (IPR) | 0.002 - 0.010 | Ensures a clean chip, avoids rubbing |

| Coolant | Liberal use of water-soluble coolant | Manages extreme thermal expansion |

| Clamping Pressure | Minimal and evenly distributed | Prevents stress creep and part deformation |

Need Precision-Machined PTFE Components?

Machining PTFE to exact specifications requires specialized expertise and a deep respect for the material's properties. At KINTEK, we have mastered the art of fabricating high-performance PTFE components—from seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and effective heat management to ensure your parts meet stringent dimensional and functional requirements, whether you need prototypes or high-volume orders.

Let us handle the challenges of PTFE machining for you. Contact our experts today to discuss your custom fabrication needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials