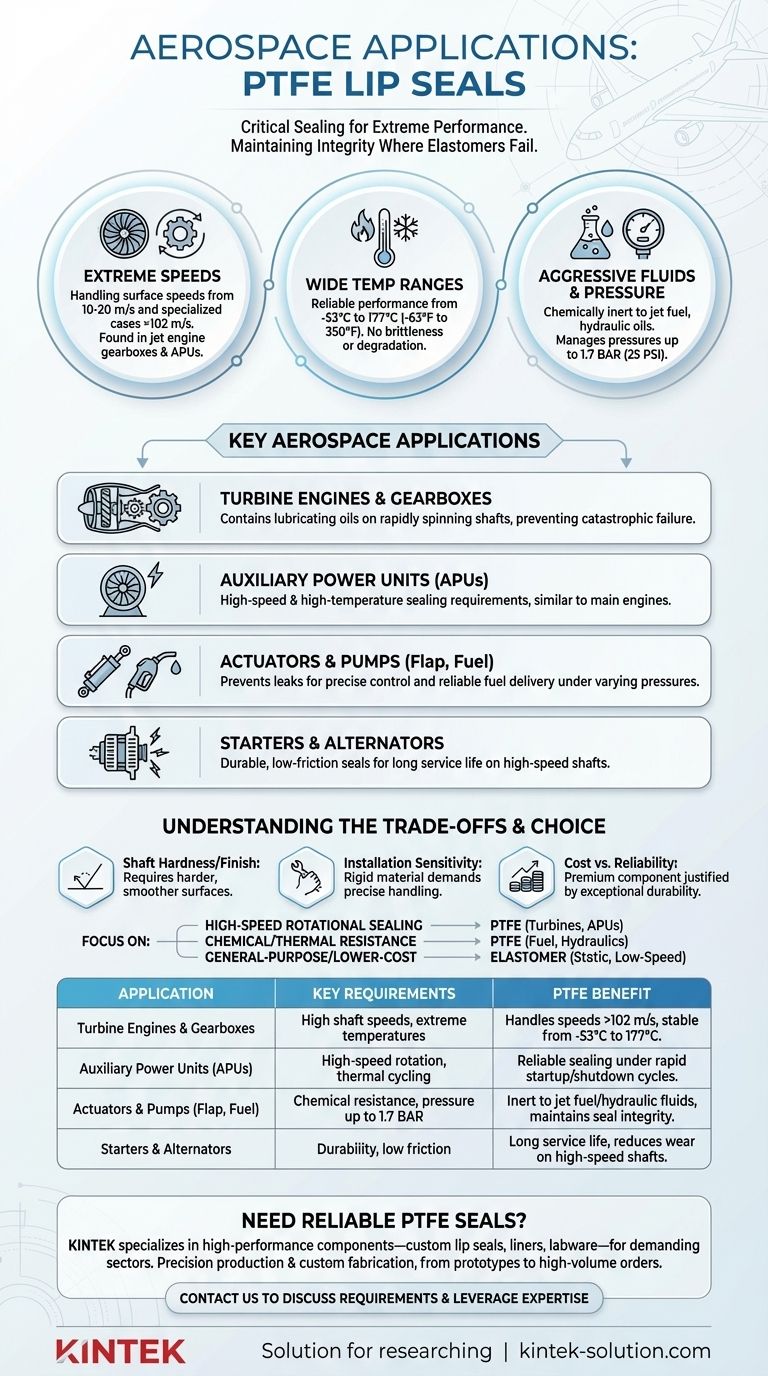

In short, PTFE lip seals are used in critical aerospace systems where extreme performance is required. Key applications include auxiliary power units (APUs), turbine engines, starters, alternators, fuel pumps, Ram Air Turbines, and flap actuators on both commercial and military aircraft.

The core reason PTFE is chosen for aerospace is its unique ability to maintain sealing integrity under conditions that cause conventional elastomer seals to fail: exceptionally high shaft speeds, wide temperature ranges, and exposure to aggressive fluids.

The Demanding Environment of Aerospace Systems

Aerospace components operate under some of the most challenging conditions imaginable. A seal isn't just a component; it's a critical failure point. Understanding these demands clarifies why a specialized material like PTFE is necessary.

Extreme Operating Speeds

Many aerospace systems involve high-speed rotating shafts. PTFE seals are engineered to handle surface speeds from 10-20 m/s and, in some specialized cases, over 102 m/s.

These speeds, found in jet engine gearboxes and APUs, would generate destructive heat and wear with standard elastomer seals.

Wide Temperature Ranges

Aircraft components must perform reliably from a cold start on the ground to extreme heat at high altitudes. PTFE seals are specified for a typical range of -53°C to 177°C (-63°F to 350°F).

This thermal stability ensures the seal remains effective and does not become brittle or degrade across the entire operational envelope.

Aggressive Fluids and Pressure

Aerospace systems rely on fluids like jet fuel and hydraulic oils, which can be corrosive to many materials. Seals must also manage internal pressures, often up to 1.7 BAR (25 PSI) in these dynamic applications.

PTFE is chemically inert, meaning it will not swell, soften, or break down when in constant contact with these aggressive compounds.

Key Aerospace Applications for PTFE Seals

Given the harsh operating environment, PTFE lip seals have become the standard in several specific, high-performance aerospace systems.

Turbine Engines and Gearboxes

This is a primary application. Seals in jet engine gearboxes must contain lubricating oils on rapidly spinning shafts, preventing leaks that could lead to catastrophic engine failure.

Auxiliary Power Units (APUs)

An APU is a small turbine engine that provides power to the aircraft on the ground. It has sealing requirements nearly identical to the main engines, demanding high-speed and high-temperature performance.

Actuators and Pumps

Flap actuators and fuel pumps are critical hydraulic and fluid systems. PTFE seals prevent leaks, ensuring precise control and reliable fuel delivery under varying pressures.

Starters and Alternators

These components are essential for engine start and electrical power generation. They feature high-speed rotating shafts that require durable, low-friction seals to ensure long service life and reliability.

Understanding the Trade-offs

While PTFE offers superior performance in extreme conditions, it's essential to recognize that it is a specialized solution with specific design considerations. It is not a universal replacement for all seal types.

Shaft Hardness and Surface Finish

To achieve a proper seal and long life, PTFE lip seals typically require a harder and smoother shaft surface finish compared to traditional elastomer seals. An improper surface can cause premature wear on the seal lip.

Installation Sensitivity

PTFE is a more rigid material than rubber-like elastomers. This characteristic demands greater care and precision during installation to avoid damaging the seal lip, which could compromise its performance.

Cost vs. Reliability

PTFE seals are a premium component, often involving a higher initial cost than standard seals. However, this cost is justified by their exceptional durability and the high price of failure in a critical aerospace system.

Making the Right Choice for Your Application

Selecting the correct seal material is a crucial engineering decision that directly impacts system reliability and safety.

- If your primary focus is high-speed rotational sealing: PTFE is the definitive choice for applications like turbine gearboxes and APUs where shaft speeds exceed the limits of elastomers.

- If your primary focus is chemical and thermal resistance: For systems handling jet fuel or hydraulic fluids across extreme temperatures, PTFE's inertness and stability are non-negotiable.

- If your primary focus is a general-purpose, lower-cost system: In static or low-speed applications with moderate temperatures, a standard elastomer seal may be a more cost-effective and suitable choice.

Ultimately, choosing a PTFE seal is a commitment to ensuring operational integrity in the most demanding environments.

Summary Table:

| Application | Key Requirements | PTFE Seal Benefits |

|---|---|---|

| Turbine Engines & Gearboxes | High shaft speeds, extreme temperatures | Handles speeds >102 m/s, stable from -53°C to 177°C |

| Auxiliary Power Units (APUs) | High-speed rotation, thermal cycling | Reliable sealing under rapid startup/shutdown cycles |

| Actuators & Pumps (Flap, Fuel) | Chemical resistance, pressure up to 1.7 BAR | Inert to jet fuel/hydraulic fluids, maintains seal integrity |

| Starters & Alternators | Durability, low friction | Long service life, reduces wear on high-speed shafts |

Need reliable PTFE seals for your aerospace systems? KINTEK specializes in manufacturing high-performance PTFE components—including custom lip seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services, from prototypes to high-volume orders, ensure your critical applications meet extreme demands. Contact us today to discuss your sealing requirements and leverage our expertise for your next project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance