In conveyor systems and for wear strips, Polytetrafluoroethylene (PTFE) offers significant advantages primarily due to its extremely low coefficient of friction, high wear resistance, and non-stick surface. These core properties result in quieter, more efficient operation, a dramatic reduction in maintenance requirements, and a longer service life for both the PTFE components and the machinery they interact with.

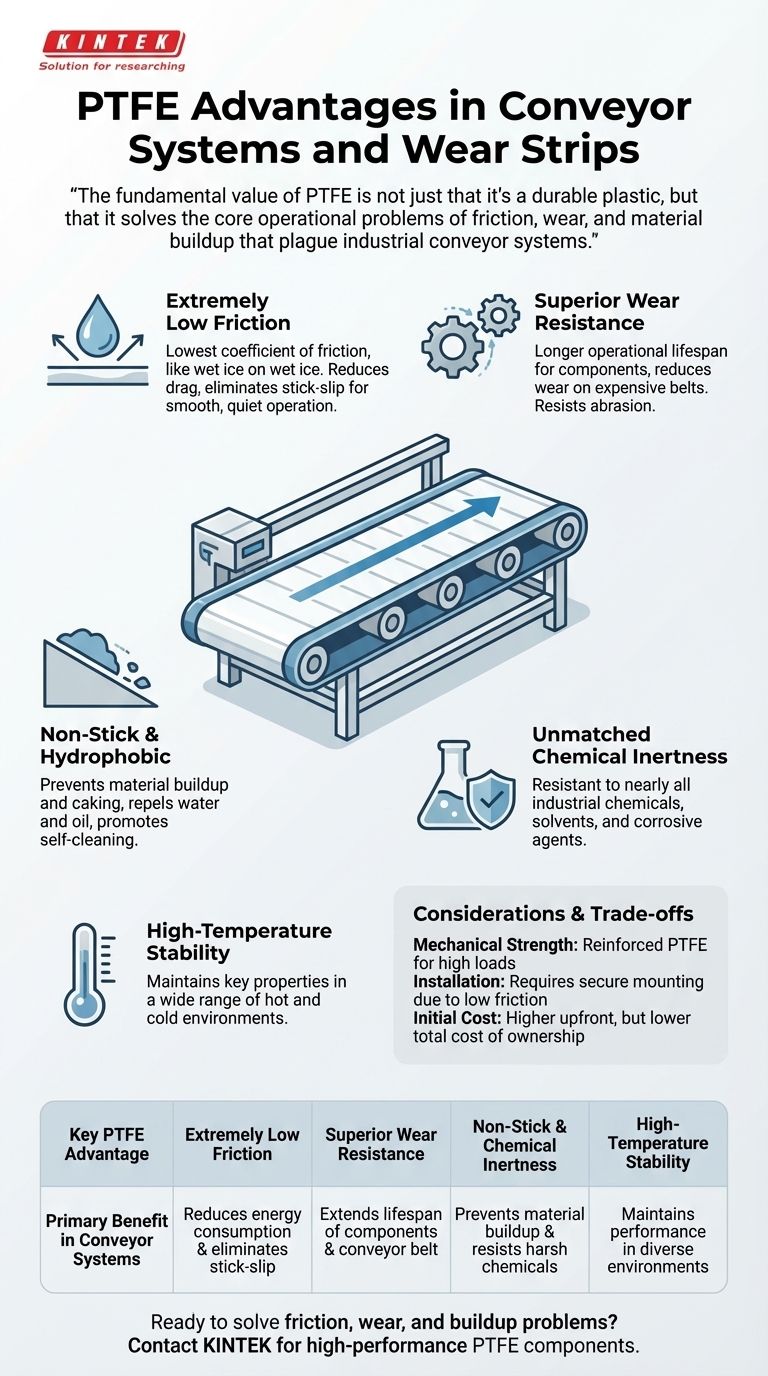

The fundamental value of PTFE is not just that it's a durable plastic, but that it solves the core operational problems of friction, wear, and material buildup that plague industrial conveyor systems. Its unique molecular properties translate directly into lower energy costs, less downtime, and greater overall productivity.

The Core Properties Driving PTFE's Performance

To understand why PTFE is so effective in these applications, we must look at its fundamental material characteristics. Each property addresses a common failure point in mechanical systems.

Exceptionally Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "slipperiness" is its most defining feature.

This property directly reduces the drag on conveyor belts as they slide over guide rails and wear strips. It also completely eliminates the "stick-slip" effect, ensuring motion is smooth and free of juddering, which is critical for precision and reducing mechanical stress.

Superior Wear Resistance

While seemingly soft, PTFE is highly resistant to wear, especially in sliding applications. The low friction means less abrasive force is generated between moving surfaces.

This results in a longer operational lifespan for PTFE wear strips and guides. Critically, it also reduces wear on the more expensive components it protects, such as the conveyor belt itself.

Non-Stick and Hydrophobic Nature

PTFE is both hydrophobic (repels water) and oleophobic (repels oil), and its surface energy is extremely low, making it non-stick. This is the same property leveraged in non-stick cookware.

In applications like chutes and hopper linings, this prevents materials from caking or building up, which can cause blockages. This non-wetting characteristic promotes a self-cleaning effect, ensuring consistent material flow.

Unmatched Chemical Inertness

PTFE is a fluoropolymer, making it chemically inert and resistant to nearly all industrial chemicals, solvents, and corrosive agents.

This allows it to be used in harsh environments, such as food processing facilities that use aggressive cleaning chemicals or in plants that handle corrosive materials, without degrading.

High-Temperature Stability

With a high melting point and a wide operating temperature range, PTFE maintains its key properties in conditions that would cause many other plastics to fail. This stability ensures reliable performance in both hot and cold environments.

Understanding the Trade-offs and Considerations

While highly effective, PTFE is not a universal solution. An objective evaluation requires understanding its limitations.

Mechanical Strength and Reinforcement

Standard PTFE is relatively soft and can be susceptible to deformation under very high loads, a phenomenon known as "creep" or cold flow.

For applications involving high compression or significant structural load, reinforced or "filled" PTFE is required. Fillers like glass fiber, carbon, graphite, or bronze are added to enhance compressive strength, durability, and wear resistance, tailoring the material to the specific demand.

Installation and Tolerances

The low friction of PTFE means it provides little resistance to motion. This must be accounted for in the design and mounting of components to ensure they remain secure. Proper installation is key to leveraging the material's benefits.

Initial Material Cost

The upfront cost of PTFE components can be higher than that of traditional materials like steel or some other plastics like UHMW (Ultra-High-Molecular-Weight polyethylene).

However, this is often offset by a lower total cost of ownership. The dramatic reduction in maintenance, downtime, and replacement of associated parts (like the belt) typically provides a clear return on the initial investment.

Making the Right Choice for Your System

Selecting the right material depends on your primary operational goal. PTFE should be viewed as a strategic component for solving specific, recurring problems.

- If your primary focus is maximizing uptime and reducing maintenance: PTFE is an excellent choice due to its long service life, wear resistance, and self-cleaning properties that prevent blockages.

- If your primary focus is improving energy efficiency and smooth operation: PTFE's ultra-low friction directly reduces the energy needed to drive the system and eliminates stick-slip for smoother, quieter performance.

- If your primary focus is operating in chemically aggressive or high-temperature environments: PTFE's chemical inertness and thermal stability make it one of the most reliable materials available.

Ultimately, integrating PTFE into your conveyor and guide systems is an investment in long-term operational reliability and efficiency.

Summary Table:

| Key PTFE Advantage | Primary Benefit in Conveyor Systems |

|---|---|

| Extremely Low Friction | Reduces energy consumption & eliminates stick-slip for smooth operation |

| Superior Wear Resistance | Extends lifespan of PTFE components and the conveyor belt itself |

| Non-Stick & Chemical Inertness | Prevents material buildup & resists harsh chemicals, reducing blockages |

| High-Temperature Stability | Maintains performance in a wide range of operating environments |

Ready to solve your friction, wear, and material buildup problems for good?

KINTEK specializes in manufacturing high-performance, custom PTFE components like seals, liners, labware, and specifically wear strips and conveyor system parts for the semiconductor, medical, laboratory, and industrial sectors.

Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get the exact PTFE solution to maximize your system's uptime, efficiency, and longevity.

Contact KINTEK today to discuss your application and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance