Fundamentally, the advantages of PTFE gaskets' low friction and non-stick properties directly translate to enhanced operational reliability and purity. The low coefficient of friction simplifies installation and removal without damaging equipment, while significantly reducing wear in moving applications. The non-stick surface prevents material buildup, which is critical for maintaining hygiene and ensuring consistent system performance.

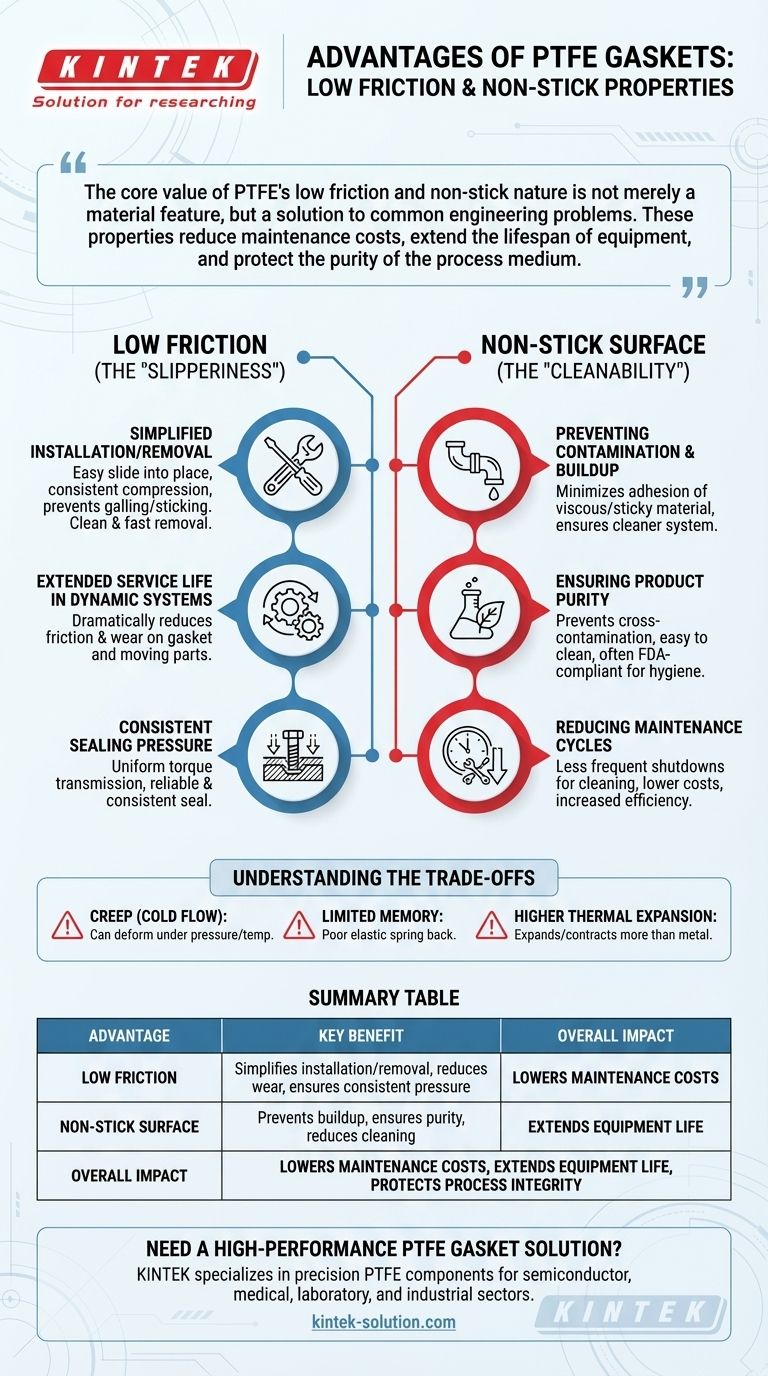

The core value of PTFE's low friction and non-stick nature is not merely a material feature, but a solution to common engineering problems. These properties reduce maintenance costs, extend the lifespan of equipment, and protect the purity of the process medium.

The Impact of Low Friction (The "Slipperiness")

The extremely low coefficient of friction of PTFE is one of its most defining characteristics. This "slipperiness" provides tangible mechanical advantages that go far beyond basic sealing.

Simplified Installation and Removal

During assembly, the low friction allows a PTFE gasket to slide easily into place. This ensures consistent compression with less torque and reduces the risk of the gasket bunching or tearing.

Critically, it also prevents galling or sticking to flange surfaces, making removal clean and fast without the need for scraping, which can damage expensive mating surfaces.

Extended Service Life in Dynamic Systems

In dynamic applications, such as in valves or rotating equipment, friction is the primary driver of wear and tear.

PTFE's slick surface dramatically reduces this friction, minimizing abrasive wear on both the gasket and the moving parts it seals against. This directly leads to a longer service life for the entire assembly.

Consistent Sealing Pressure

The ability to achieve a reliable seal depends on applying uniform pressure across the gasket surface.

Because PTFE does not stick or bind during compression, the applied torque from bolts translates more evenly into sealing force. This helps create a more reliable and consistent seal from the outset.

The Power of a Non-Stick Surface (The "Cleanability")

PTFE's non-stick, or anti-adhesion, property is chemically inherent. This characteristic is essential in applications where purity and flow are paramount.

Preventing Contamination and Buildup

In processes involving viscous, sticky, or particulate-laden media, material can adhere to and build up on gasket surfaces. This buildup can impede flow or break off, contaminating the system.

PTFE's non-stick surface minimizes this material adhesion, ensuring a cleaner system and more consistent operation over time.

Ensuring Product Purity

In hygiene-critical industries like food processing, biotechnology, and pharmaceuticals, preventing cross-contamination is non-negotiable.

The non-stick surface is easy to clean and prevents previous batches from clinging to the gasket, ensuring product purity. Many PTFE grades are FDA-compliant for this specific reason.

Reducing Maintenance Cycles

When gaskets resist material buildup, the need for frequent system shutdowns for cleaning is significantly reduced.

This directly lowers maintenance costs, minimizes downtime, and increases overall operational efficiency.

Understanding the Trade-offs of PTFE

While its properties are highly advantageous, PTFE is not a universal solution. An objective assessment requires understanding its limitations.

Tendency to Creep (Cold Flow)

PTFE has a tendency to "creep" or cold flow under sustained pressure and temperature. This means the material can slowly deform over time, potentially leading to a loss of bolt torque and sealing pressure.

Limited Memory and Elasticity

Unlike rubber or elastomeric gaskets, PTFE has very poor "memory." It does not spring back to its original shape effectively after being compressed. This makes it less suitable for applications with significant thermal cycling or pressure fluctuations where the gasket must adapt.

Higher Thermal Expansion

PTFE expands and contracts with temperature changes more than the metal flanges it typically seals. This differential expansion must be accounted for in the system design to maintain a reliable seal across a wide temperature range.

Making the Right Choice for Your Application

Selecting the right gasket requires matching the material's strengths to your primary operational goal.

- If your primary focus is operational efficiency and maintenance: The low friction is key, as it drastically cuts downtime and labor associated with gasket installation and replacement.

- If your primary focus is product purity and hygiene: The non-stick, FDA-compliant surface is the critical advantage, ensuring clean operation and preventing cross-contamination.

- If your primary focus is long-term reliability in dynamic systems: The low coefficient of friction is paramount for minimizing wear on moving components and extending the life of the seal.

Ultimately, leveraging these two core properties of PTFE moves a gasket from a simple component to a strategic asset for system integrity and performance.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Low Friction | Simplifies installation/removal, reduces wear in dynamic systems, ensures consistent sealing pressure. |

| Non-Stick Surface | Prevents material buildup, ensures product purity, and reduces cleaning downtime. |

| Overall Impact | Lowers maintenance costs, extends equipment life, and protects process integrity. |

Need a high-performance PTFE gasket solution for your application?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom gaskets, seals, and liners. Our expertise ensures you get a part that leverages these critical properties to maximize your system's reliability and purity.

We serve the semiconductor, medical, laboratory, and industrial sectors, providing solutions from prototypes to high-volume orders.

Contact KINTEK today to discuss your specific requirements and let our experts help you enhance your operational efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments