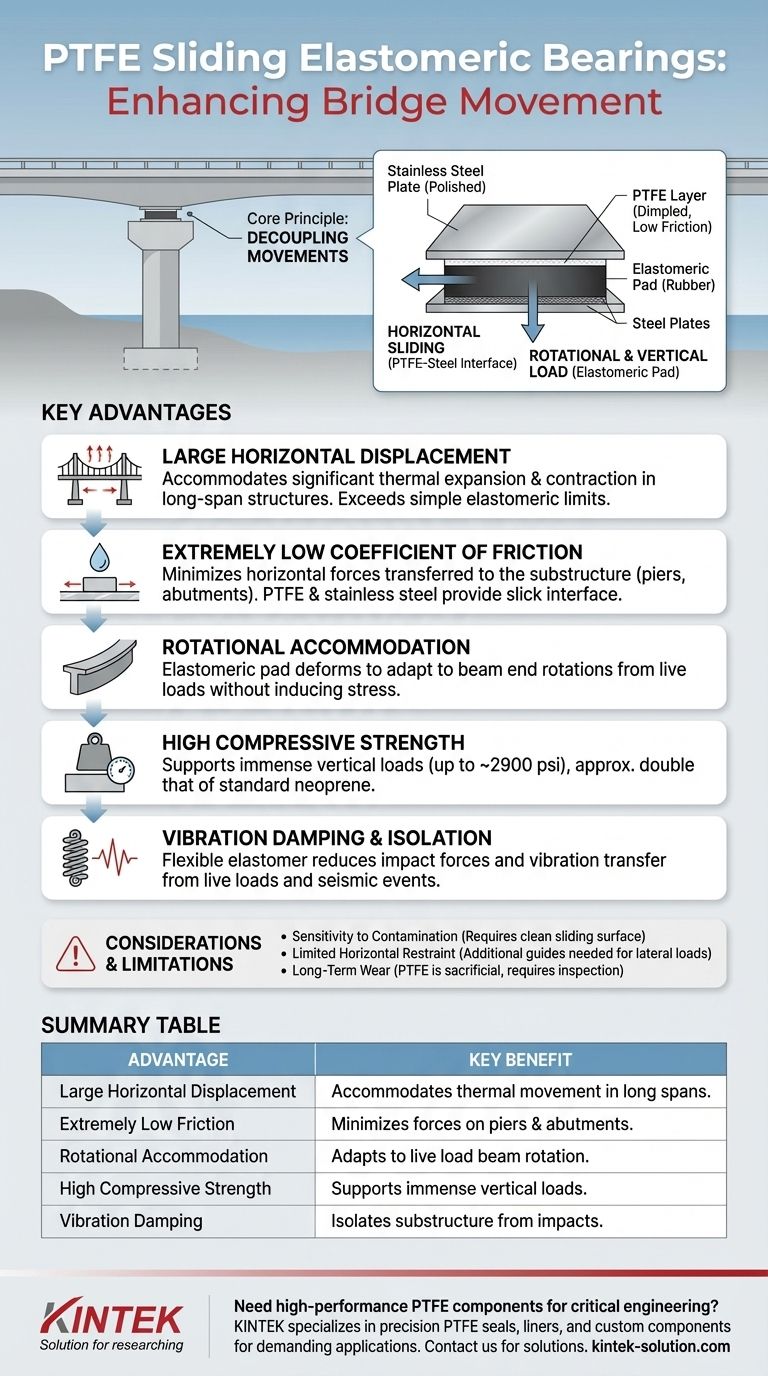

At its core, a PTFE sliding elastomeric bearing enhances bridge movement by adding a low-friction sliding surface to a traditional elastomeric pad. This design allows the bridge superstructure to move freely horizontally over large distances with minimal resistance, while the underlying elastomer still accommodates vertical loads and rotational deflections. This combination solves a critical engineering challenge for long-span and continuous-beam bridges.

The fundamental advantage is decoupling movements. The elastomeric pad handles compression and rotation, while the separate PTFE-stainless steel interface handles large horizontal sliding. This specialization allows for far greater displacement than a simple elastomeric bearing could ever accommodate through shear deformation alone.

The Core Principle: How PTFE Transforms the Bearing

A standard elastomeric bearing works by deforming—stretching and compressing—to absorb movement. This has inherent limits. Adding a PTFE layer fundamentally changes the mechanics of how the bearing accommodates horizontal forces.

The Key Components

A PTFE sliding bearing consists of an elastomeric pad bonded to a steel plate. A thin, dimpled layer of PTFE (polytetrafluoroethylene) is then bonded to the top. This PTFE surface slides against a highly polished stainless steel plate that is attached to the bridge's sole plate.

Separating Load from Movement

The elastomeric pad's primary job becomes supporting the immense vertical load of the bridge and accommodating beam end rotation through its flexibility.

Simultaneously, the PTFE layer's sole purpose is to provide an incredibly slick surface. This allows the bridge deck to glide horizontally, accommodating movements from thermal expansion, contraction, and other forces without stressing the underlying pier or abutment.

Key Advantages Explained

This unique design delivers several distinct advantages critical for modern bridge engineering.

Accommodating Large Horizontal Displacement

Because movement occurs via sliding rather than shearing rubber, the potential for horizontal displacement is significantly increased. This makes these bearings ideal for bridges with large spans or multi-span continuous beams that experience substantial thermal expansion and contraction.

Extremely Low Coefficient of Friction

PTFE has one of the lowest friction coefficients of any known solid, especially when sliding against polished stainless steel. The dimples on the PTFE surface act as reservoirs for lubricant, further reducing this friction. This minimizes the horizontal forces transferred to the bridge's substructure, improving overall stability.

Adapting to Rotational Deflection

The underlying elastomeric pad retains its flexibility. As the bridge beam deflects under live loads (like traffic), it rotates slightly at the ends. The elastomer deforms easily to accommodate this rotational movement without inducing significant stress.

High Compressive Strength

PTFE can withstand immense pressure—up to 2900 psi (200 Kgf/cm2), approximately double that of standard neoprene. This high compressive strength is essential for reliably supporting the concentrated vertical loads from the bridge girders.

Reducing Impact and Vibration

The combination of the flexible elastomer and the sliding surface provides an excellent isolation effect. It helps dampen and reduce the impact forces transferred to the substructure from live loads and seismic events, enhancing the bridge's durability and longevity.

Understanding the Trade-offs and Limitations

While highly effective, these bearings are not a universal solution. Understanding their operational limitations is key to successful implementation.

Sensitivity to Contamination

The performance of the low-friction sliding surface is highly dependent on its cleanliness. Debris, grit, or corrosion on the stainless steel plate can score the PTFE layer, dramatically increasing friction and impairing the bearing's function.

Limited Horizontal Restraint

By design, a standard sliding bearing provides minimal resistance to horizontal movement. If a design requires restraining the bridge against certain lateral forces (like wind or seismic loads), separate guide systems or restraints must be incorporated.

Long-Term Wear

Although PTFE is highly durable, it is a sacrificial component. Over decades of thermal cycles and traffic-induced movements, the PTFE layer will eventually wear. These bearings require periodic inspection to ensure the sliding surface remains effective throughout the bridge's service life.

Making the Right Choice for Your Bridge Design

The decision to use a PTFE sliding elastomeric bearing should be driven by the specific movement demands of the structure.

- If your primary focus is accommodating large thermal expansion and contraction: The nearly unrestricted horizontal sliding capability makes these bearings the ideal choice for long-span structures.

- If your primary focus is reducing horizontal forces on piers: The extremely low friction coefficient ensures minimal stress is transferred from the superstructure to the substructure, which can lead to more economical pier and foundation designs.

- If your primary focus is supporting a beam that experiences both rotation and significant translation: The dual-function design, separating rotation and sliding, provides a robust and efficient solution that a single-material bearing cannot.

Ultimately, these bearings provide engineers with a critical tool to manage the inevitable movements of large bridge structures safely and efficiently.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Large Horizontal Displacement | Accommodates significant thermal expansion/contraction in long-span bridges. |

| Extremely Low Friction | Minimizes horizontal forces transferred to piers and abutments. |

| Rotational Accommodation | Underlying elastomer adapts to beam end rotations from live loads. |

| High Compressive Strength | Supports immense vertical loads (up to ~2900 psi). |

| Vibration Damping | Isolates substructure from impact forces and seismic events. |

Need high-performance PTFE components for your critical engineering applications?

KINTEK specializes in the precision manufacturing of PTFE seals, liners, and custom components for demanding industries like infrastructure, semiconductor, medical, and laboratory. Our expertise ensures the material integrity and performance required for applications like bridge bearings.

We offer custom fabrication from prototypes to high-volume orders, ensuring your specifications are met with exacting standards.

Contact KINTEK today to discuss how our PTFE solutions can enhance your project's durability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support