For the most demanding applications, PTFE O-rings offer a unique combination of extreme chemical resistance, a vast operational temperature range, and an exceptionally low coefficient of friction. Their distinct properties make them a critical sealing solution where conventional rubber O-rings would quickly degrade and fail.

PTFE is not a simple drop-in replacement for a standard rubber O-ring. It is a specialized engineering material chosen for its elite performance in harsh chemical and thermal environments, but this performance comes with a critical trade-off in mechanical elasticity.

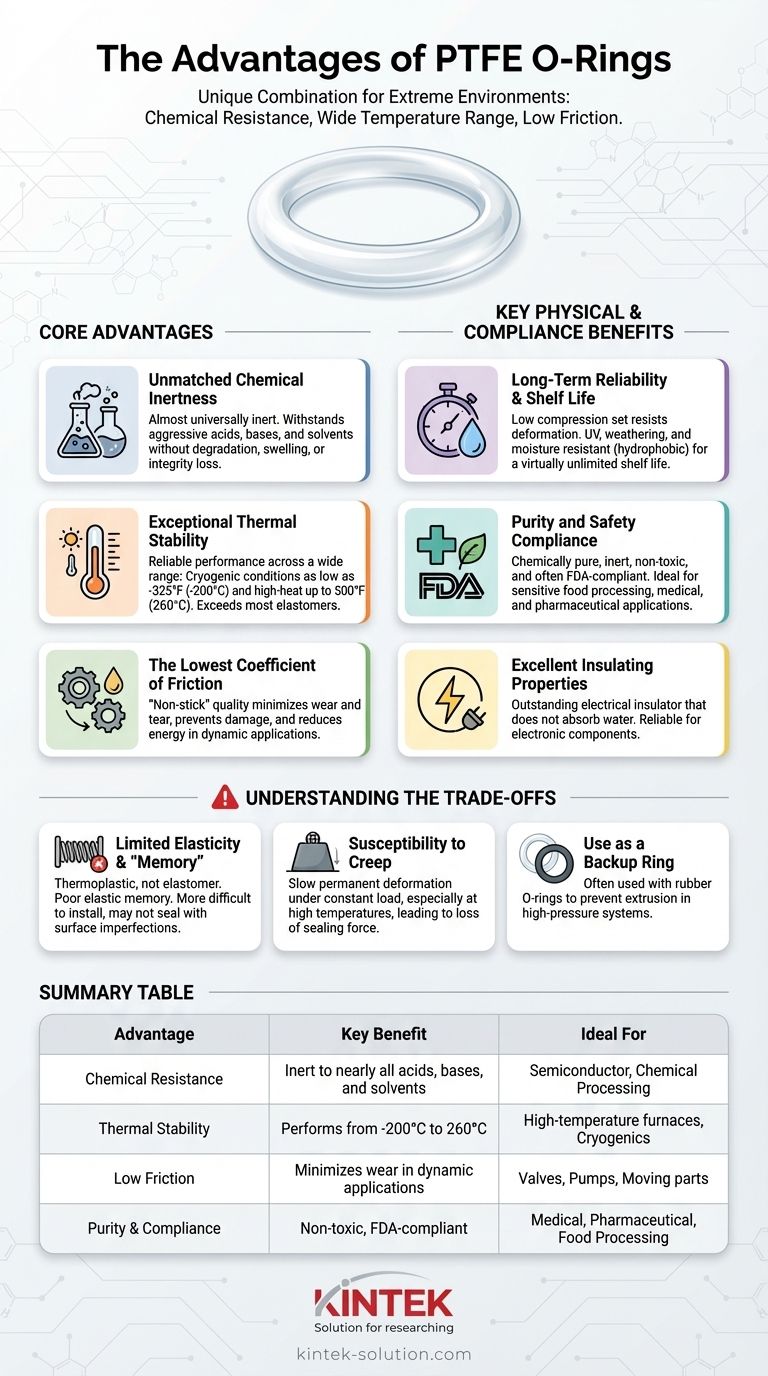

The Core Advantages of PTFE O-Rings

Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer, and its molecular structure is the source of its most significant benefits as a sealing material.

Unmatched Chemical Inertness

The carbon-fluorine bonds in PTFE are exceptionally strong, making the material almost universally inert.

This means PTFE O-rings can withstand exposure to nearly all industrial chemicals, including aggressive acids, bases, and solvents, without degrading, swelling, or losing their integrity.

Exceptional Thermal Stability

PTFE O-rings maintain their properties across an incredibly wide temperature range.

They can reliably perform in cryogenic conditions as low as -325°F (-200°C) and in high-heat applications up to 500°F (260°C), far exceeding the limits of most elastomers.

The Lowest Coefficient of Friction

Of any known solid material, PTFE has one of the lowest coefficients of friction.

This "non-stick" quality is invaluable in dynamic applications, as it minimizes wear and tear on moving parts, prevents damage to sensitive surfaces, and reduces the energy required for operation.

Key Physical and Compliance Benefits

Beyond its core resistances, PTFE offers several other practical advantages that contribute to its reliability and suitability for specialized industries.

Long-Term Reliability and Shelf Life

PTFE has a very low compression set, meaning it resists permanent deformation after being compressed. This ensures a long-lasting and reliable seal over time.

Furthermore, it is resistant to UV radiation, weathering, and moisture (hydrophobic), giving it a virtually unlimited shelf life without degradation.

Purity and Safety Compliance

Because it is a chemically pure and inert material, PTFE is non-toxic and often FDA-compliant.

This makes PTFE O-rings an ideal choice for sensitive applications in the food processing, medical, and pharmaceutical industries where contamination is not an option.

Excellent Insulating Properties

PTFE is an outstanding electrical insulator and does not absorb water. This makes it a reliable sealing choice for electronic components or in applications where electrical conductivity would be a problem.

Understanding the Trade-offs: When PTFE May Not Be the Right Choice

While its advantages are significant, PTFE is not a universal solution. Its unique mechanical properties introduce critical limitations that must be understood to prevent seal failure.

Limited Elasticity and "Memory"

The most important distinction is that PTFE is a thermoplastic, not a true elastomer like rubber. It has poor elastic memory, meaning it does not "spring back" to its original shape effectively after being compressed.

This lack of elasticity means it can be more difficult to install without special care and may not provide a reliable seal in applications with surface imperfections or frequent pressure cycles.

Susceptibility to Creep

Under constant load or pressure (especially at elevated temperatures), PTFE is susceptible to creep, which is a slow, permanent deformation over time.

This can lead to a loss of sealing force in certain static applications if not accounted for during the design phase.

Use as a Backup Ring

Because of its rigidity and resistance to deformation under pressure, PTFE is often used as a backup ring in conjunction with a traditional rubber O-ring.

In high-pressure systems, the PTFE backup ring sits behind the elastomer O-ring and prevents it from extruding into the clearance gap, thereby extending the life and pressure rating of the primary seal.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the specific demands of your system.

- If your primary focus is sealing against aggressive chemicals: PTFE is one of the most reliable and inert materials available.

- If your primary focus is performance in extreme temperatures (hot or cold): PTFE's wide operational range makes it a superior choice over most elastomers.

- If your primary focus is a dynamic application requiring low friction: PTFE's non-stick surface will minimize wear and ensure smooth operation.

- If your primary focus is high-pressure static sealing: Consider using a PTFE backup ring to support a more traditional elastomer O-ring for the best combination of elasticity and extrusion resistance.

Ultimately, choosing a PTFE O-ring is a deliberate engineering decision for environments where nothing else will survive.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Chemical Resistance | Inert to nearly all acids, bases, and solvents | Semiconductor, chemical processing |

| Thermal Stability | Performs from -200°C to 260°C | High-temperature furnaces, cryogenics |

| Low Friction | Minimizes wear in dynamic applications | Valves, pumps, moving parts |

| Purity & Compliance | Non-toxic, FDA-compliant | Medical, pharmaceutical, food processing |

Need a PTFE sealing solution that can handle your most demanding environment?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom O-rings, seals, and labware for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype or a high-volume order, our expertise ensures a reliable seal that meets your exact specifications for chemical resistance, temperature extremes, and purity.

Contact our engineering team today to discuss your application and get a custom solution quote.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance

- How do PTFE seals perform under pressurized conditions? Achieving Reliable Sealing in Demanding Environments

- What are the benefits of using PTFE seals in demanding industries? Solve Extreme Sealing Challenges

- What are PTFE seals and why are they considered a reliable solution for extreme environments? Engineered for Harsh Conditions

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions