Beyond simply preventing seal extrusion, PTFE and PEEK backup rings provide a significant upgrade in performance through their low friction, high chemical resistance, and ability to operate reliably at high continuous temperatures. These properties make them essential components in chemically aggressive and high-performance industrial applications.

The core decision between PTFE and PEEK is not about which is better, but which is right for the specific challenge. PTFE offers the ultimate in chemical and thermal resistance, while PEEK delivers unparalleled mechanical strength and wear resistance for extreme pressure environments.

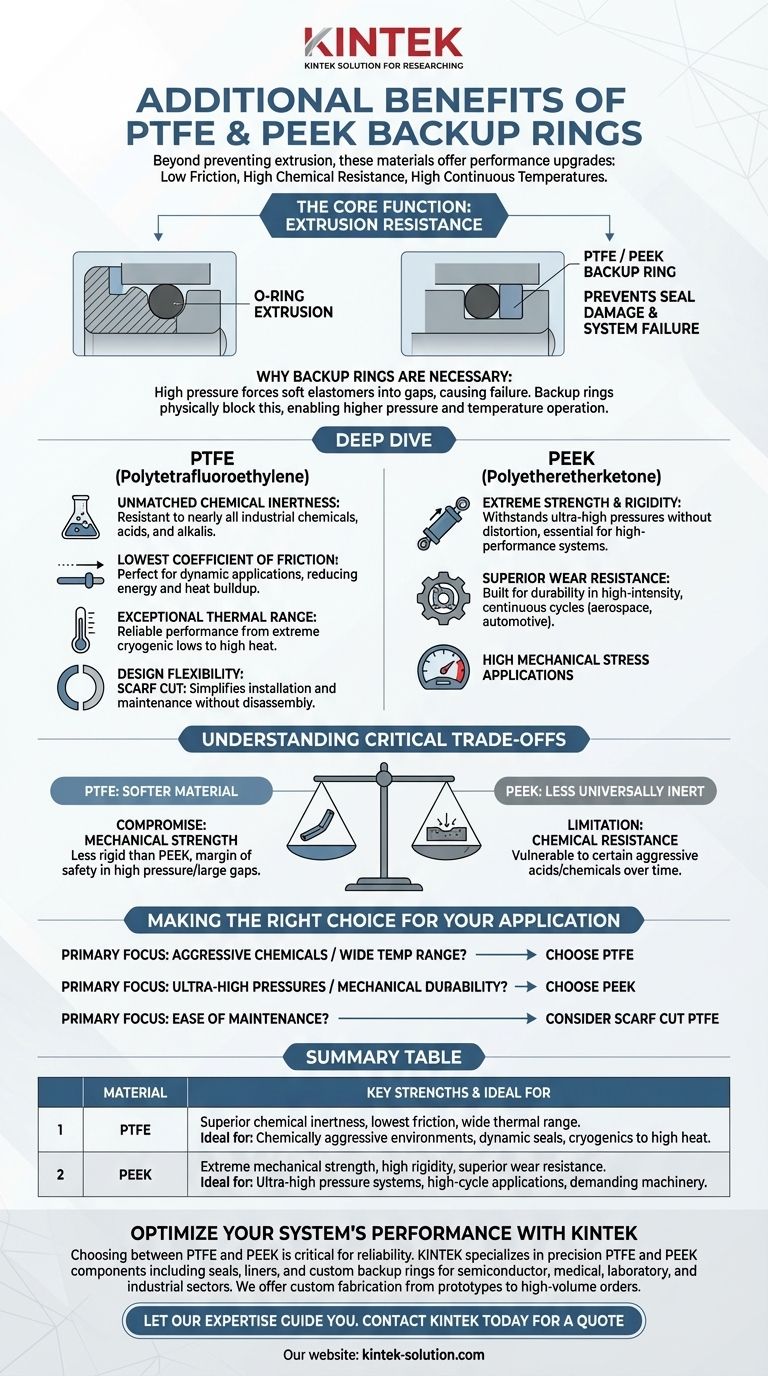

The Core Function: A Foundation of Extrusion Resistance

Why Backup Rings are Necessary

In any high-pressure hydraulic or pneumatic system, soft elastomer seals like O-rings are at risk of being forced into the small clearance gap between moving parts. This process, known as extrusion, quickly leads to seal damage and system failure.

Backup rings are rigid, precisely-machined rings installed next to the O-ring to physically block this extrusion gap. This allows the system to operate at much higher pressures and temperatures than it could with an O-ring alone.

The Material Advantage

Materials like PTFE (Polytetrafluoroethylene) and PEEK (Polyetheretherketone) are ideal for this role because they are dimensionally stable and have excellent compressive strength. They will not deform or flow under the immense forces that cause an elastomer to fail.

Deep Dive: When to Choose PTFE

PTFE is often the material of choice when environmental conditions are the primary challenge. Its unique properties make it exceptionally versatile.

Unmatched Chemical Inertness

PTFE is famously resistant to nearly all industrial chemicals, acids, and alkalis. This makes it the default choice for equipment in chemical processing, pipelines, and valves where seals are exposed to highly corrosive media.

The Lowest Coefficient of Friction

With one of the lowest friction coefficients of any solid material, PTFE is perfect for dynamic applications requiring smooth movement and minimal wear. This reduces operational energy and heat buildup in components like piston rings and dynamic seals.

Exceptional Thermal Range

PTFE maintains its integrity and properties across an incredibly wide temperature spectrum, performing reliably in environments from extreme cryogenic lows to high heat.

Design Flexibility: The Scarf Cut

PTFE backup rings are often manufactured in a "split" or "scarf cut" design. This allows the ring to be slightly expanded and snapped into a groove without requiring a complete disassembly of the equipment, simplifying installation and maintenance.

Deep Dive: When to Choose PEEK

PEEK excels where mechanical stress is the dominant factor. It is specified for applications where strength and durability are non-negotiable.

Extreme Strength and Rigidity

PEEK possesses exceptionally high tensile strength and rigidity. This allows it to withstand ultra-high pressures without distortion, making it essential for high-performance hydraulic systems and high-pressure valves.

Superior Wear Resistance

In applications with high-intensity, continuous cycles, PEEK's mechanical toughness and wear resistance ensure long-term performance. It is built for durability in demanding aerospace, automotive, and industrial machinery.

Understanding the Critical Trade-offs

Neither material is a universal solution. Understanding their limitations is key to proper selection and avoiding premature failure.

The PTFE Compromise: Mechanical Strength

While chemically and thermally robust, PTFE is a softer material than PEEK. In applications with extremely high pressures combined with large extrusion gaps, PEEK's superior rigidity provides a greater margin of safety against mechanical failure.

The PEEK Limitation: Chemical Resistance

PEEK has excellent chemical resistance to many fluids, but it is not as universally inert as PTFE. Certain aggressive acids and chemicals can degrade PEEK over time, making PTFE the safer choice in the most corrosive environments.

Making the Right Choice for Your Application

Your final decision should be guided by the single greatest demand your system will place on the component.

- If your primary focus is exposure to aggressive chemicals or a very wide temperature range: Choose PTFE for its unparalleled chemical inertness and thermal stability.

- If your primary focus is withstanding ultra-high pressures and ensuring long-term mechanical durability: Select PEEK for its superior strength, rigidity, and wear resistance.

- If your primary focus is ease of maintenance on existing equipment: Consider a split (scarf cut) PTFE backup ring to simplify installation and reduce downtime.

Choosing the right advanced material transforms a simple backup ring from a supporting part into a critical component for maximizing system reliability.

Summary Table:

| Material | Key Strengths | Ideal For |

|---|---|---|

| PTFE | Superior chemical inertness, lowest friction, wide thermal range | Chemically aggressive environments, dynamic seals, cryogenics to high heat |

| PEEK | Extreme mechanical strength, high rigidity, superior wear resistance | Ultra-high pressure systems, high-cycle applications, demanding machinery |

Optimize Your System's Performance with the Right Backup Ring

Choosing between PTFE and PEEK is critical for the reliability and longevity of your equipment in demanding environments. The right material selection can prevent costly downtime and seal failure.

KINTEK specializes in manufacturing precision PTFE and PEEK components—including seals, liners, and custom backup rings—for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit and superior performance for your specific application.

Let our expertise guide you to the optimal solution. Contact KINTEB today to discuss your requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications