Beyond its famous non-stick surface, Polytetrafluoroethylene (PTFE) offers a powerful combination of physical and thermal properties that make it uniquely advantageous for laboratory use. Its benefits extend far beyond chemical inertness, including an exceptionally wide temperature range, superior sealing performance due to low compression set, and a hydrophobic nature that prevents swelling and absorption of critical samples.

The true value of PTFE in a laboratory is not just its resistance to chemicals, but its ability to ensure experimental integrity and operational reliability. It provides a stable, non-contaminating, and physically resilient material that protects the purity of samples and the longevity of equipment across a vast range of conditions.

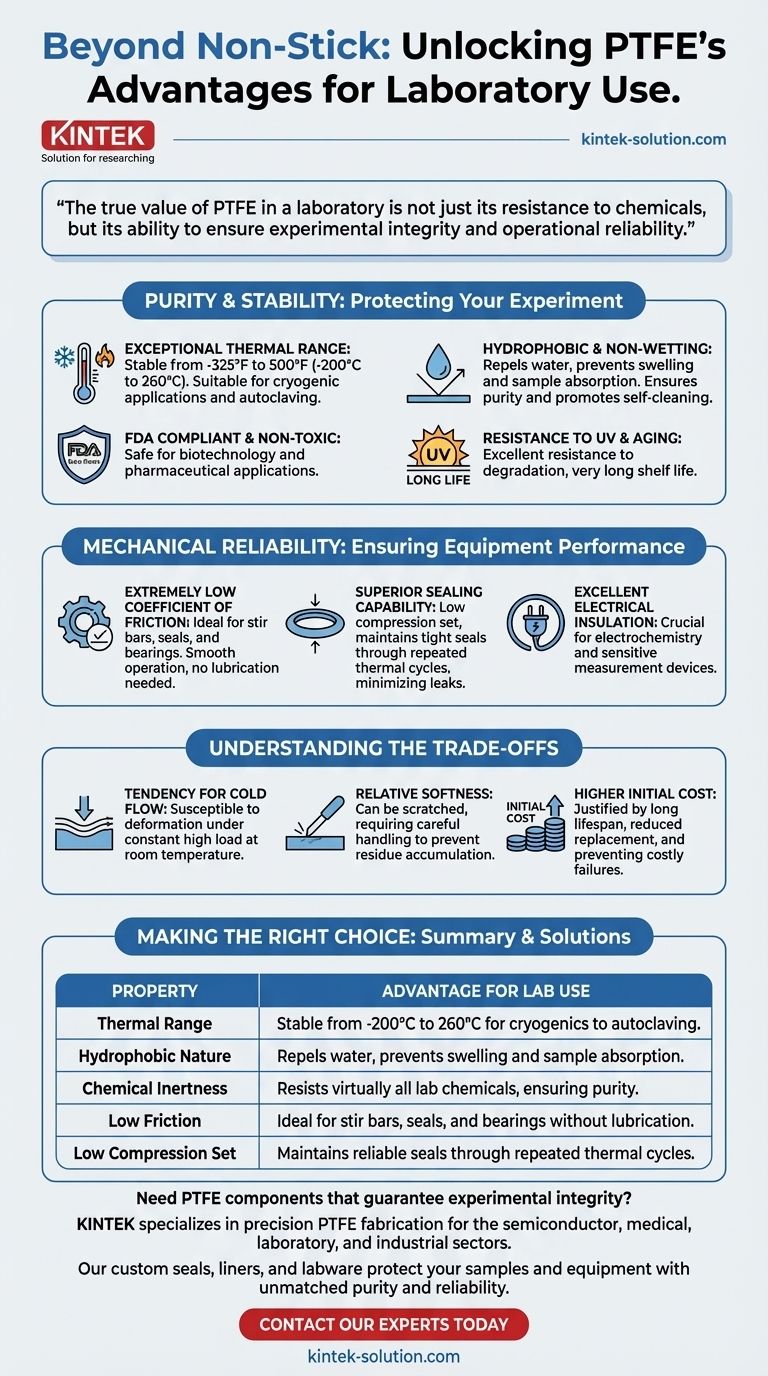

Purity and Stability: Protecting Your Experiment

For any laboratory, preventing contamination and ensuring the stability of materials is paramount. PTFE offers several properties that directly contribute to the accuracy and repeatability of your work.

### Exceptional Thermal Range

PTFE maintains its properties across an incredibly wide temperature spectrum, typically from -325°F to 500°F (-200°C to 260°C). This makes it suitable for both cryogenic applications and high-temperature processes, including autoclaving for sterilization.

### Hydrophobic and Non-Wetting Nature

Unlike many other plastics, PTFE is hydrophobic, meaning it repels water and does not swell when exposed to aqueous solutions or solvents. This non-wetting property is critical because it prevents the material from absorbing analytes or reagents, which eliminates a common source of cross-contamination and ensures sample purity. In some applications, this promotes a "self-cleaning" effect as liquids bead up and roll off easily.

### FDA Compliance and Non-Toxicity

PTFE is non-toxic and often FDA compliant, making it a safe and reliable choice for applications in biotechnology, pharmaceutical research, and food science where leaching from materials is a major concern.

### Resistance to UV and Aging

The material shows excellent resistance to degradation from UV radiation and has a very long shelf life. This stability ensures that components do not become brittle or change their properties over time, even with prolonged storage or use in UV-based experiments.

Mechanical Reliability: Ensuring Equipment Performance

Lab equipment must be durable and perform predictably. PTFE’s mechanical characteristics provide long-lasting, low-maintenance performance for seals, bearings, and other critical components.

### Extremely Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material. This is why it is the standard for magnetic stir bars and is ideal for bearings, seals, and other moving parts in lab equipment, as it ensures smooth operation with minimal wear and no need for lubrication.

### Superior Sealing Capability

PTFE O-rings and gaskets exhibit a low compression set and excellent recovery properties. This means they do not easily deform permanently under pressure, allowing them to maintain a tight, reliable seal through many thermal cycles and repeated use, minimizing leaks and equipment downtime.

### Excellent Electrical Insulation

PTFE is an exceptional electrical insulator. This property is crucial for apparatus used in electrochemistry or when working with sensitive electronic measurement devices where stray electrical currents could interfere with results.

Understanding the Trade-offs

No material is perfect. To make an informed decision, it's important to understand PTFE's limitations in a lab context.

### Tendency for Cold Flow

Under a constant, high load at room temperature, pure PTFE can be susceptible to "cold flow" or creep, where the material slowly deforms over time. This makes it unsuitable for high-load structural applications where precise dimensions must be maintained under constant pressure.

### Relative Softness

Compared to metals or hard engineering plastics, PTFE is a relatively soft material. It can be easily scratched or scored, which could potentially create sites for residue to accumulate if not handled with care.

### Higher Initial Cost

PTFE components are generally more expensive upfront than those made from glass or more common plastics like polypropylene. However, its long lifespan, reduced need for replacement, and ability to prevent costly experimental failures often justify the investment.

Making the Right Choice for Your Lab

Selecting the right material is a strategic decision that impacts your results, budget, and efficiency.

- If your primary focus is sample purity and preventing cross-contamination: PTFE's hydrophobic and non-wetting properties are its greatest advantage, ensuring nothing is added to or taken from your samples.

- If your primary focus is equipment reliability and longevity: Its thermal stability, low-friction nature, and excellent sealing capabilities reduce maintenance and replacement costs over the long term.

- If your primary focus is work involving extreme temperatures or harsh chemicals: Its exceptionally wide operating temperature range and near-universal chemical inertness make it the default choice for safety and performance.

Ultimately, choosing PTFE is an investment in the confidence and integrity of your experimental outcomes.

Summary Table:

| Property | Advantage for Lab Use |

|---|---|

| Thermal Range | Stable from -200°C to 260°C for cryogenics to autoclaving |

| Hydrophobic Nature | Repels water, prevents swelling and sample absorption |

| Chemical Inertness | Resists virtually all lab chemicals, ensuring purity |

| Low Friction | Ideal for stir bars, seals, and bearings without lubrication |

| Low Compression Set | Maintains reliable seals through repeated thermal cycles |

Need PTFE components that guarantee experimental integrity?

KINTEK specializes in precision PTFE fabrication for the semiconductor, medical, laboratory, and industrial sectors. Our custom seals, liners, and labware protect your samples and equipment with unmatched purity and reliability.

Contact our experts today to discuss your specific application, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions