No, Teflon is not biodegradable. As a synthetic fluoropolymer, its chemical bonds are exceptionally strong, preventing it from being broken down by microorganisms. When discarded, products coated with Teflon (PTFE) will persist in landfills for hundreds, if not thousands, of years.

The central issue with Teflon's environmental impact is its extreme persistence. While modern manufacturing has phased out the most problematic chemicals like PFOA, the final product itself is a "forever material" that does not break down in nature.

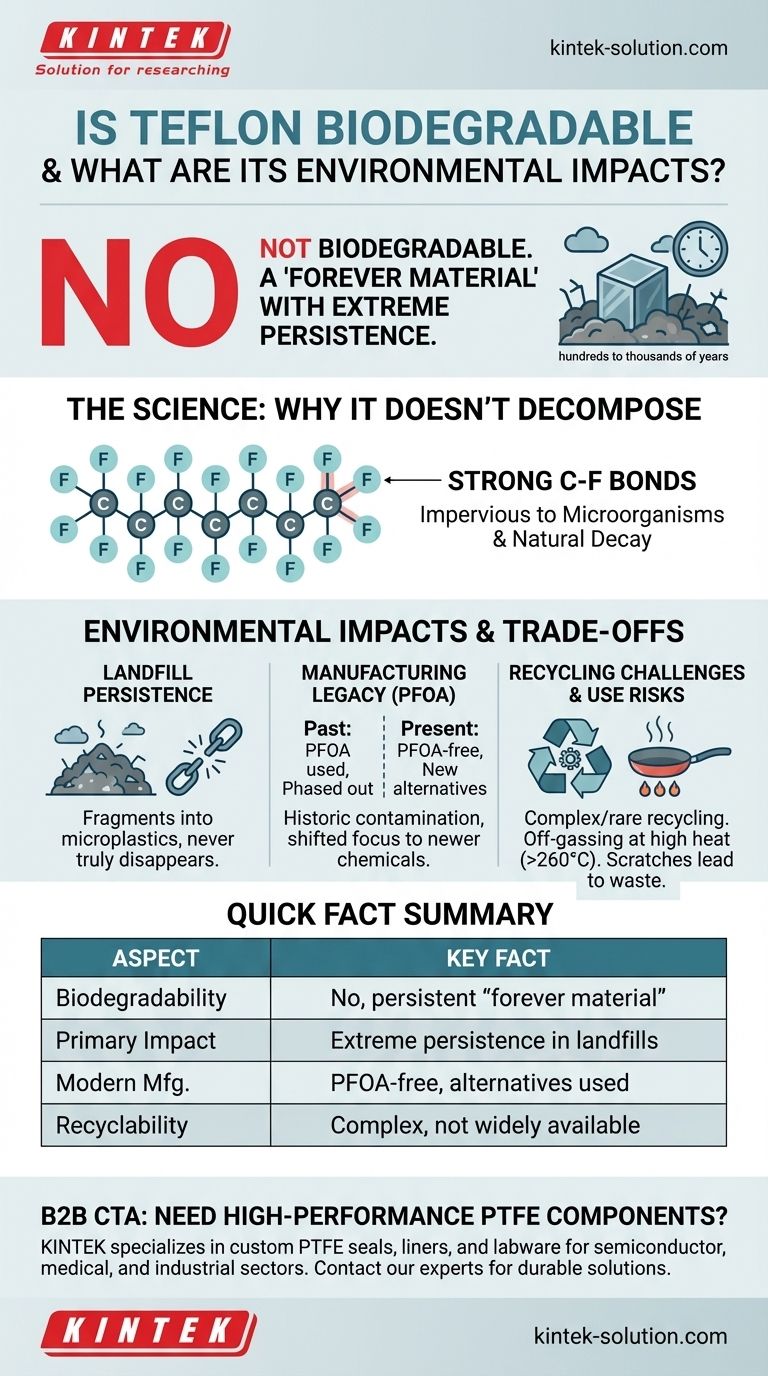

The Core Issue: Extreme Persistence

Teflon, the brand name for Polytetrafluoroethylene (PTFE), is engineered for stability. The very properties that make it an excellent non-stick coating—chemical inertness and thermal resistance—also make it impervious to natural decay.

Why Teflon Doesn't Decompose

The molecular structure of Teflon consists of a chain of carbon atoms completely surrounded by fluorine atoms. The carbon-fluorine bond is one of the strongest single bonds in organic chemistry.

This powerful bond is what gives Teflon its resistance to heat, chemicals, and water. It is also what prevents bacteria and fungi from breaking the material down.

The Landfill Problem

When a Teflon-coated product is thrown away, it does not decompose. It simply sits in a landfill, potentially fragmenting into smaller plastic particles over long periods but never truly disappearing or returning to the ecosystem.

Manufacturing's Environmental Legacy

The environmental impact of Teflon extends beyond its disposal. The historical manufacturing process has left a significant and controversial legacy.

The PFOA Connection

For decades, a chemical called PFOA (perfluorooctanoic acid) was used as a processing aid in the manufacturing of Teflon. PFOA is a type of PFAS, often called a "forever chemical," known for its persistence in the environment and its association with health risks.

A Critical Distinction: Past vs. Present

It is crucial to understand that major global manufacturers, under regulatory pressure, began phasing out the use of PFOA in the early 2000s. Today, Teflon-branded products are no longer made using PFOA.

However, the historical use of these chemicals has led to widespread environmental contamination, and the focus has now shifted to the impact of the newer, alternative chemicals used in the process.

Understanding the Trade-offs and Risks

While valuable for its properties, Teflon comes with a clear set of limitations and potential downsides that contribute to its overall environmental footprint.

The Recycling Challenge

Although PTFE is technically recyclable, the process is complex and not widely available. The infrastructure for collecting, separating, and reprocessing Teflon-coated materials is extremely limited, meaning the vast majority of products end up in landfills.

Risk of Off-Gassing at High Heat

When heated to extreme temperatures (generally above 500°F or 260°C), well beyond normal cooking ranges, Teflon coatings can begin to break down and release polymer fumes. While not a risk under normal use, overheating cookware should always be avoided.

Susceptibility to Damage

Teflon coatings are relatively soft and can be easily scratched by metal utensils. A damaged coating can flake off, and while small flakes are considered non-toxic if ingested, a significantly damaged pan loses its effectiveness and is often discarded, contributing to more waste.

Making an Informed Decision

Understanding the complete lifecycle of Teflon allows you to use products containing it more responsibly and consider when alternatives might be more appropriate.

- If your primary focus is minimizing landfill waste: Choose durable products and care for them properly to maximize their lifespan. When a product must be discarded, check for local specialized recycling programs, though they are rare.

- If your primary focus is avoiding "forever chemicals": Be assured that modern Teflon is made without PFOA, but recognize that the material itself (PTFE) is a persistent fluoropolymer that will not biodegrade.

- If your primary focus is safe daily use: Use Teflon-coated cookware on low to medium heat, avoid using metal utensils, and discard any pans with significant scratches or peeling.

Ultimately, recognizing that a material's impact extends from its creation to its disposal is the key to making more sustainable choices.

Summary Table:

| Aspect | Key Fact |

|---|---|

| Biodegradability | No, it is a persistent "forever material" |

| Primary Environmental Impact | Extreme persistence in landfills |

| Modern Manufacturing | PFOA is no longer used, but alternatives are in use |

| Recyclability | Technically possible but complex and not widely available |

Need high-performance, precision-engineered PTFE components? KINTEK specializes in the custom fabrication of PTFE seals, liners, and labware for the semiconductor, medical, and industrial sectors. We prioritize material integrity and precision production, from prototypes to high-volume orders. Contact our experts today to discuss how our durable PTFE solutions can meet your specific requirements while understanding the material's properties.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications

- What are the primary applications of PTFE? Unlocking High-Performance Solutions

- What industrial applications does PTFE have? Unlock Performance in Extreme Environments

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE