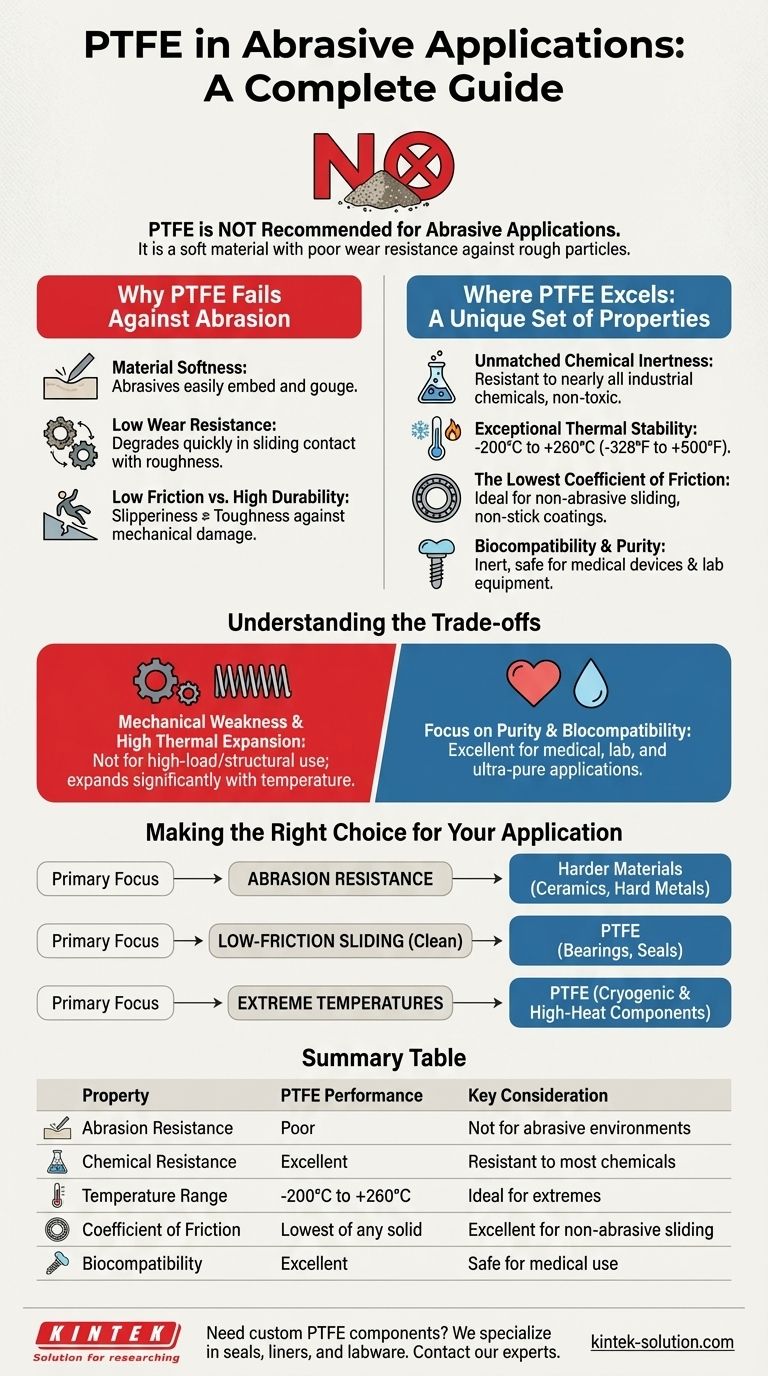

No, PTFE is not recommended for abrasive applications. As a fundamentally soft material, Polytetrafluoroethylene (PTFE) has very poor wear resistance when exposed to hard or rough particles. It will degrade quickly in any environment where it is subjected to scraping, grinding, or friction from abrasive media.

While PTFE's softness makes it entirely unsuitable for abrasive conditions, its true value lies in a unique and powerful combination of extreme temperature resistance, chemical inertness, and the lowest coefficient of friction of any solid material.

Why PTFE Fails Against Abrasion

The very properties that make PTFE useful in some applications are liabilities in others. Its mechanical characteristics are the primary reason for its failure in abrasive environments.

The Problem of Material Softness

PTFE is one of the softer engineering plastics. This low surface hardness means that abrasive particles can easily embed themselves into the material or gouge the surface, leading to rapid material loss and component failure.

Low Wear Resistance

Softness directly correlates to low wear resistance. In applications involving sliding contact with rough surfaces or slurries containing hard particles, PTFE will simply wear away far more quickly than harder polymers or ceramics.

Low Friction vs. High Durability

A common point of confusion is PTFE's famous low-friction, or "non-stick," quality. This property describes its inherent slipperiness, not its ability to withstand mechanical damage. While it reduces friction in clean environments, this does not translate to durability against abrasive forces.

Where PTFE Excels: A Unique Set of Properties

Understanding where PTFE fails is only half the story. Its value comes from a combination of properties that make it an elite material for very specific, non-abrasive challenges.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals and solvents. This makes it a premier choice for seals, gaskets, and linings in chemical processing. Because it is non-toxic and does not leach contaminants, it is also ideal for ultra-pure applications.

Exceptional Thermal Stability

PTFE performs reliably across an incredibly wide temperature range, typically from -200°C to +260°C (-328°F to +500°F). This allows it to be used in everything from cryogenic equipment to high-temperature industrial seals without degrading.

The Lowest Coefficient of Friction

PTFE's extremely low friction makes it perfect for non-abrasive sliding applications. It is widely used for bearings, slide plates, and non-stick coatings where smooth, low-effort movement is critical.

Biocompatibility and Purity

Due to its inert nature, PTFE is highly biocompatible and widely used in the medical field. It is found in life-saving devices like catheters, surgical sutures, and components for laboratory equipment where safety and reliability are paramount.

Understanding the Trade-offs

No material is perfect. The key to successful engineering is choosing a material whose strengths align with your application's demands and whose weaknesses are not critical liabilities.

Mechanical Weakness is the Core Limitation

Beyond poor abrasion resistance, PTFE's softness means it is not suitable for high-load or structural applications. It can deform under sustained pressure, a phenomenon known as "creep."

High Coefficient of Thermal Expansion

PTFE expands and contracts with temperature changes more than most other engineering materials. This must be accounted for in designs requiring tight tolerances across a range of operating temperatures to avoid component seizure or failure.

Making the Right Choice for Your Application

Selecting the correct material requires a clear understanding of your primary operational challenge.

- If your primary focus is abrasion resistance: PTFE is the wrong choice. You should investigate harder materials like ceramics, hard-faced metals, or specialized wear-resistant polymers.

- If your primary focus is low-friction sliding in a clean environment: PTFE is an excellent candidate for bearings, seals, and non-stick surfaces where abrasive particles are not present.

- If your primary focus is chemical purity or biocompatibility: PTFE is a world-class material for medical devices, laboratory equipment, and handling ultra-pure fluids.

- If your primary focus is extreme temperature performance: PTFE's vast operating range makes it a reliable choice for seals and components in both cryogenic and high-heat settings.

Understanding PTFE's specific strengths and critical weaknesses is the key to leveraging its unique capabilities without risking material failure.

Summary Table:

| Property | PTFE Performance | Key Consideration |

|---|---|---|

| Abrasion Resistance | Poor | Not recommended for abrasive environments |

| Chemical Resistance | Excellent | Resistant to nearly all industrial chemicals |

| Temperature Range | -200°C to +260°C | Ideal for extreme temperature applications |

| Coefficient of Friction | Lowest of any solid | Excellent for non-abrasive sliding applications |

| Biocompatibility | Excellent | Safe for medical and laboratory use |

Need a custom PTFE component that leverages its true strengths?

At KINTEK, we specialize in precision manufacturing of PTFE seals, liners, and labware for industries where chemical inertness, extreme temperature stability, and low friction are critical—such as semiconductor, medical, and laboratory applications.

We provide custom fabrication from prototypes to high-volume orders, ensuring your components are perfectly suited to your specific operational needs.

Contact our experts today to discuss how our PTFE solutions can solve your unique challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments