PTFE O-rings are utilized across nearly every major industrial sector where performance under extreme conditions is non-negotiable. Their unique properties make them essential components in demanding fields such as chemical processing, food and beverage manufacturing, pharmaceuticals, automotive, and aerospace. They are the go-to solution for sealing applications involving corrosive chemicals, wide temperature ranges, and high-purity requirements.

The widespread adoption of PTFE is not accidental. It stems from a unique combination of extreme chemical inertness, broad temperature tolerance, and low-friction properties, making it the default choice for the most demanding static sealing applications.

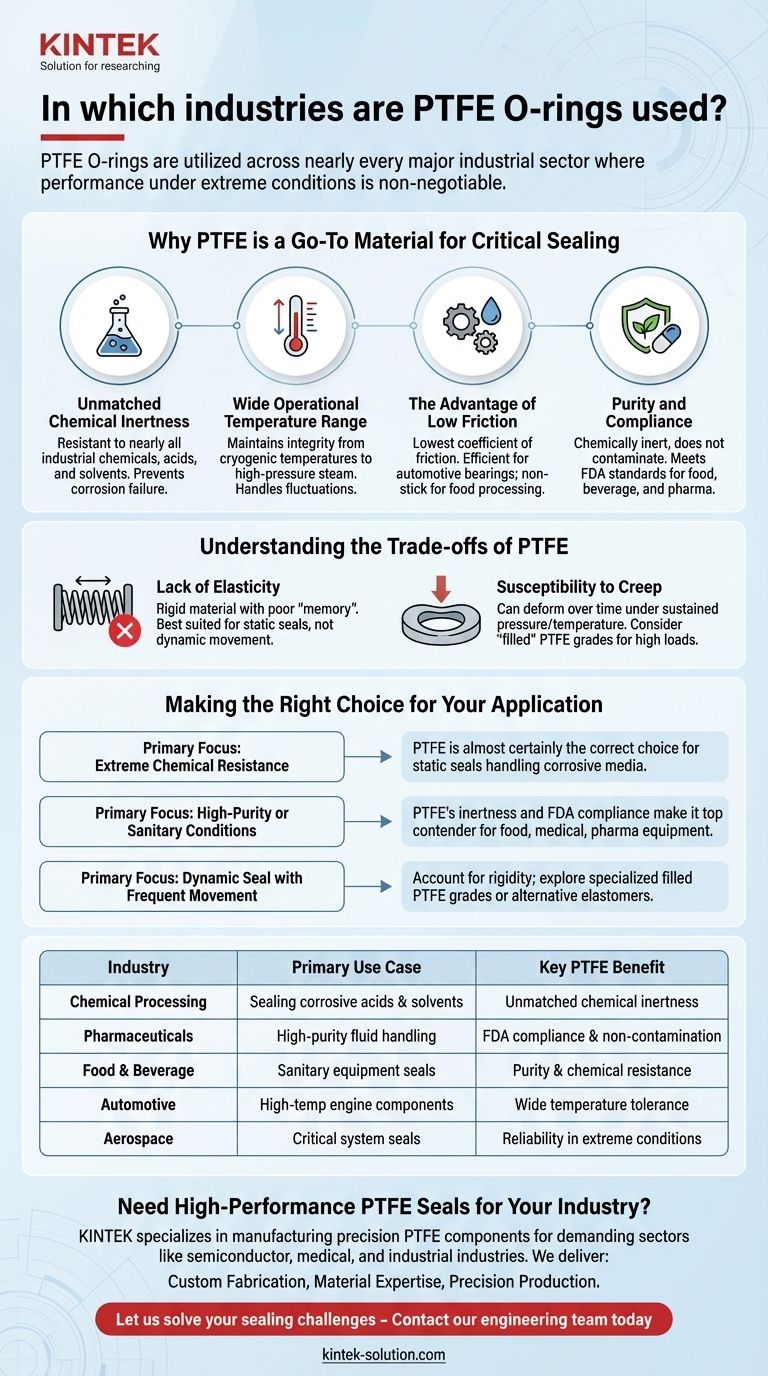

Why PTFE is a Go-To Material for Critical Sealing

The value of Polytetrafluoroethylene (PTFE) comes from a set of core properties that solve common industrial challenges better than most other materials. Understanding these traits explains its presence in so many critical systems.

Unmatched Chemical Inertness

PTFE is famously resistant to nearly all industrial chemicals, acids, and solvents. This makes it an essential material in environments where corrosion could lead to catastrophic failure.

This property is the primary reason for its heavy use in chemical manufacturing plants, acid processing facilities, and oil and gas pipelines.

Wide Operational Temperature Range

PTFE seals maintain their integrity across an exceptionally broad range of temperatures. They can withstand the high-pressure steam found in power plants and the cryogenic temperatures required in other specialized processes.

This stability prevents seal failure caused by temperature fluctuations, which is a common issue in many manufacturing and processing operations.

The Advantage of Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This inherent slipperiness is invaluable.

In automotive applications, this translates to more efficient piston rings and bearings. In food processing, it ensures that materials do not stick to machinery, maintaining purity and flow.

Purity and Compliance

Because PTFE is chemically inert, it does not contaminate the media it comes into contact with. This is a critical requirement for highly regulated industries.

Its ability to meet FDA standards makes it a staple in the food, beverage, and pharmaceutical industries, where preventing contamination is a primary safety and operational concern.

Understanding the Trade-offs of PTFE

While its properties are exceptional, PTFE is not a universal solution. An expert understands its limitations as well as its strengths.

Lack of Elasticity

Unlike rubber or other elastomers, PTFE is a relatively rigid material. It has poor "memory" and does not spring back to its original shape effectively after being compressed.

This makes pure PTFE O-rings best suited for static seals, such as those in flanges and container lids, rather than dynamic seals that experience constant movement.

Susceptibility to Creep

Under sustained pressure and temperature, PTFE can slowly deform over time, a phenomenon known as "creep." This can eventually compromise the integrity of a seal.

Engineers must account for this behavior during the design phase, especially in high-load applications, sometimes opting for "filled" PTFE grades that include additives to improve creep resistance.

Installation Challenges

The rigidity of PTFE can make installation more difficult than with a flexible rubber O-ring. Care must be taken to avoid scratching or deforming the ring during assembly, as this can create a leak path.

Making the Right Choice for Your Application

Selecting the correct sealing material requires matching its properties to your primary operational goal.

- If your primary focus is extreme chemical resistance: PTFE is almost certainly the correct choice, especially for static seals handling corrosive or aggressive media.

- If your primary focus is high-purity or sanitary conditions: PTFE's inertness and compliance with FDA standards make it a top contender for food, medical, and pharmaceutical equipment.

- If your primary focus is a dynamic seal with frequent movement: You must account for PTFE's rigidity and might need to explore specialized filled PTFE grades or alternative elastomers.

Ultimately, understanding PTFE's unique strengths and limitations is the key to leveraging it effectively in demanding industrial environments.

Summary Table:

| Industry | Primary Use Case | Key PTFE Benefit |

|---|---|---|

| Chemical Processing | Sealing corrosive acids & solvents | Unmatched chemical inertness |

| Pharmaceuticals | High-purity fluid handling | FDA compliance & non-contamination |

| Food & Beverage | Sanitary equipment seals | Purity & chemical resistance |

| Automotive | High-temp engine components | Wide temperature tolerance |

| Aerospace | Critical system seals | Reliability in extreme conditions |

Need High-Performance PTFE Seals for Your Industry?

KINTEK specializes in manufacturing precision PTFE components, including O-rings, seals, liners, and custom labware. We serve demanding sectors like semiconductor, medical, laboratory, and industrial industries where material performance is critical.

We deliver:

- Custom Fabrication: From prototypes to high-volume production runs.

- Material Expertise: Optimal PTFE grade selection for chemical resistance, temperature stability, and purity.

- Precision Production: Tight tolerances for reliable sealing in extreme conditions.

Let us solve your sealing challenges – Contact our engineering team today for a consultation on your specific application requirements.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- How do PTFE seals perform under pressurized conditions? Achieving Reliable Sealing in Demanding Environments

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance

- What are the benefits of using PTFE seals in demanding industries? Solve Extreme Sealing Challenges

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions