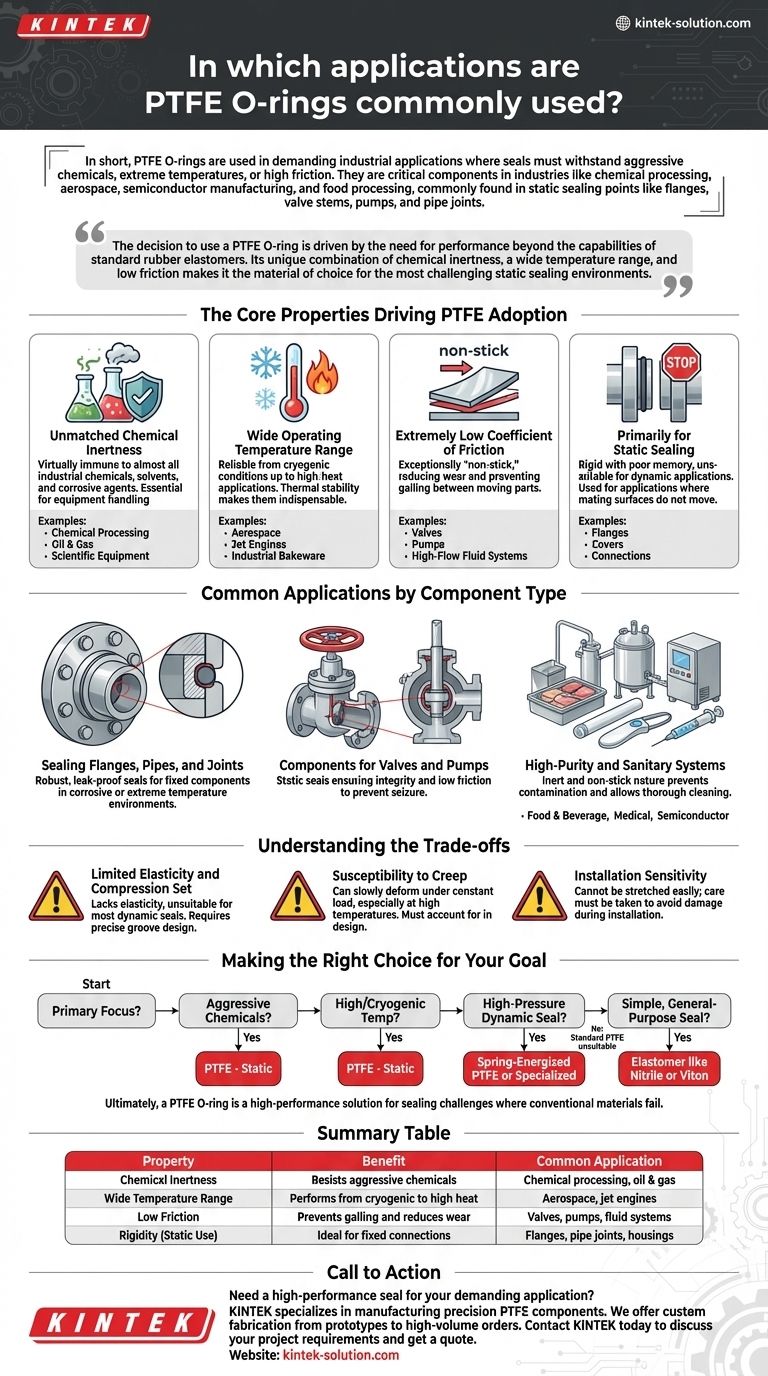

In short, PTFE O-rings are used in demanding industrial applications where seals must withstand aggressive chemicals, extreme temperatures, or high friction. They are critical components in industries like chemical processing, aerospace, semiconductor manufacturing, and food processing, commonly found in static sealing points like flanges, valve stems, pumps, and pipe joints.

The decision to use a PTFE O-ring is driven by the need for performance beyond the capabilities of standard rubber elastomers. Its unique combination of chemical inertness, a wide temperature range, and low friction makes it the material of choice for the most challenging static sealing environments.

The Core Properties Driving PTFE Adoption

To understand where PTFE O-rings are used, you must first understand why they are chosen over more common and flexible materials. Their selection is a deliberate engineering choice based on a few elite properties.

Unmatched Chemical Inertness

PTFE is virtually immune to almost all industrial chemicals, solvents, and corrosive agents. This makes it an essential material for equipment that handles aggressive substances.

You will find it in chemical processing plants, oil and gas pipelines, and scientific equipment where exposure would degrade standard seals almost instantly.

Wide Operating Temperature Range

PTFE O-rings perform reliably across an exceptionally broad temperature spectrum, from cryogenic conditions up to high-heat applications.

This thermal stability makes them indispensable in aerospace components, jet engines, and industrial bakeware where other materials would become brittle or melt.

Extremely Low Coefficient of Friction

Often recognized by its brand name Teflon®, PTFE has one of the lowest friction coefficients of any solid material. It is exceptionally "non-stick."

This property is highly valued in valves, pumps, and high-flow fluid systems, as it reduces wear and prevents galling between moving or connected parts.

Primarily for Static Sealing

A key characteristic of PTFE is its rigidity. Unlike rubber, it is not elastic and has poor "memory," meaning it does not spring back to its original shape well after being compressed.

Because of this, solid PTFE O-rings are almost exclusively used for static seals—applications where the two mating surfaces do not move relative to each other, such as in flanges, covers, and connections.

Common Applications by Component Type

PTFE's properties make it the ideal solution for sealing specific types of hardware across multiple industries.

Sealing Flanges, Pipes, and Joints

The most common use for PTFE O-rings is creating a robust, leak-proof seal between fixed components.

This includes pipe flanges, cylinder connections, and equipment housings that contain corrosive fluids or are subject to extreme temperatures.

Components for Valves and Pumps

Within complex fluid-handling equipment, PTFE O-rings serve as static seals in valve stems, pump housings, and manifolds.

Their chemical resistance ensures the integrity of the seal, while their low friction prevents seizure during assembly and maintenance.

High-Purity and Sanitary Systems

In food, beverage, and medical manufacturing, preventing contamination is paramount.

PTFE's inert and non-stick nature ensures that nothing leaches into the product and that the system can be easily and thoroughly cleaned. It is commonly used in food processing equipment, medical devices, and semiconductor manufacturing tools.

Understanding the Trade-offs

While powerful, PTFE is not a universal solution. Its limitations are as important to understand as its strengths.

Limited Elasticity and Compression Set

The primary drawback of solid PTFE is its lack of elasticity. It will not compress and rebound like a rubber O-ring.

This makes it unsuitable for most dynamic sealing applications (where parts move) and requires more precise groove design to ensure a proper seal is made upon installation.

Susceptibility to Creep

Under a constant compressive load, especially at elevated temperatures, PTFE can slowly deform over time in a process known as "creep."

Engineers must account for this behavior in high-pressure joint design to prevent a loss of sealing force over the component's lifetime.

Installation Sensitivity

Due to its rigidity, a PTFE O-ring cannot be stretched into place as easily as a standard elastomer O-ring.

Care must be taken during installation to avoid scratching or deforming the ring, which could compromise the seal.

Making the Right Choice for Your Goal

Selecting the right seal material requires matching its properties to the demands of the application.

- If your primary focus is sealing aggressive chemicals: PTFE is almost always the correct choice for static applications.

- If your primary focus is resistance to high or cryogenic temperatures: PTFE is a top-tier candidate for any static seal.

- If your primary focus is a high-pressure dynamic seal: A standard PTFE O-ring is unsuitable; investigate spring-energized PTFE seals or other specialized materials.

- If your primary focus is a simple, general-purpose seal: A more cost-effective elastomer like Nitrile (Buna-N) or Viton (FKM) is likely the better option.

Ultimately, a PTFE O-ring is a high-performance solution for sealing challenges where conventional materials are guaranteed to fail.

Summary Table:

| Property | Benefit | Common Application |

|---|---|---|

| Chemical Inertness | Resists aggressive chemicals | Chemical processing, oil & gas |

| Wide Temperature Range | Performs from cryogenic to high heat | Aerospace, jet engines |

| Low Friction | Prevents galling and reduces wear | Valves, pumps, fluid systems |

| Rigidity (Static Use) | Ideal for fixed connections | Flanges, pipe joints, housings |

Need a high-performance seal for your demanding application?

KINTEK specializes in manufacturing precision PTFE components, including O-rings, seals, liners, and custom labware. Our expertise is critical for industries like semiconductor, medical, and chemical processing where material performance is non-negotiable.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact seal solution for your extreme environment.

Contact KINTEK today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers