In the demanding world of aerospace engineering, PTFE spring-energized seals are critical components used where standard seals would fail. You will find them in high-performance applications such as fuel systems, cryogenic propulsion lines, flight control actuators, and jet engine gearboxes. Their selection is driven by an unparalleled ability to function reliably across extreme temperature variations, from cryogenic cold to engine heat, and in the vacuum of high altitude.

The core reason PTFE spring-energized seals are ubiquitous in aerospace is not a single feature, but their unique combination of material resilience and mechanical design. They provide a constant, reliable sealing force in environments where temperature, pressure, and aggressive fluids would cause conventional elastomer seals to degrade and fail.

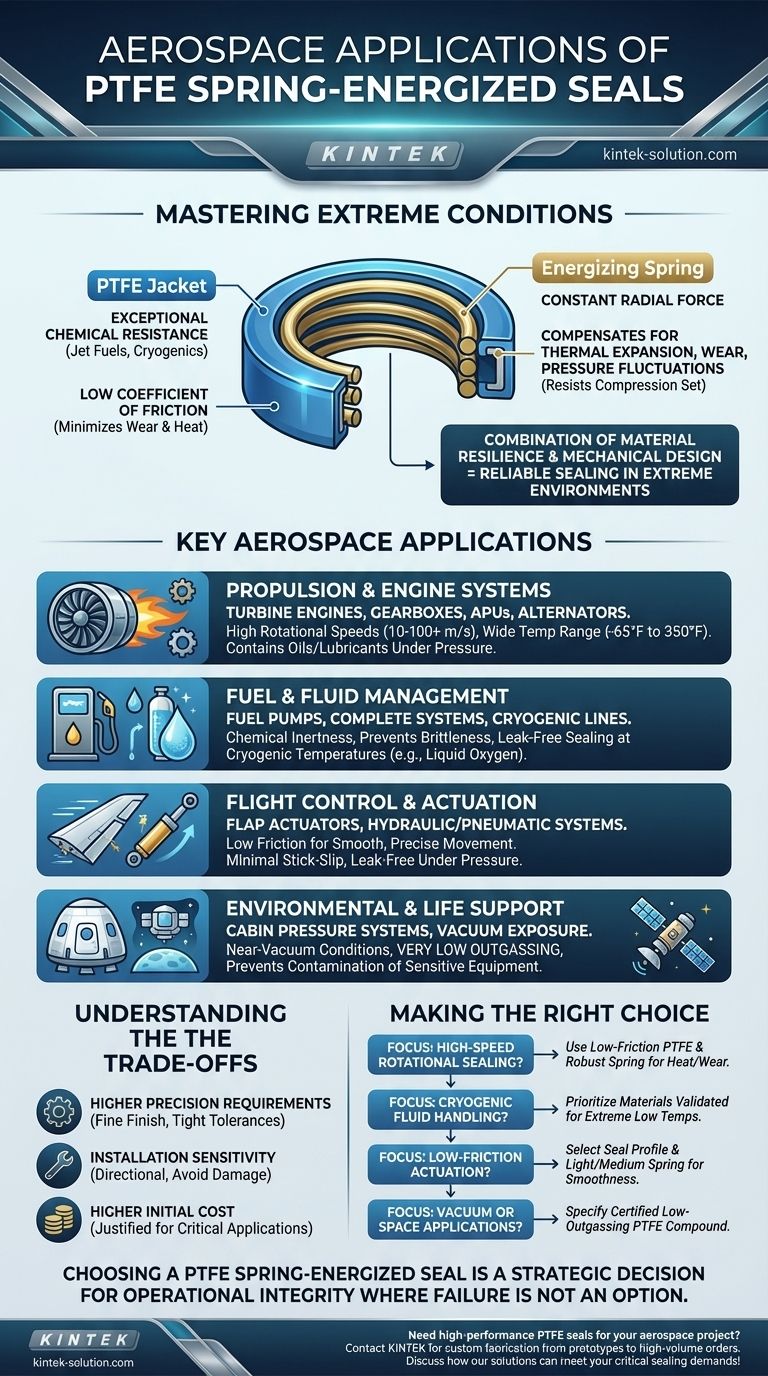

How PTFE Spring-Energized Seals Master Extreme Conditions

To understand their application, you must first understand their design. These are not simple O-rings; they are sophisticated components engineered for reliability.

The Role of the PTFE Jacket

The outer seal jacket is made from Polytetrafluoroethylene (PTFE), a fluoropolymer known for its remarkable properties.

It provides exceptional chemical resistance against aggressive jet fuels, hydraulic fluids, and cryogenic liquids like liquid oxygen or hydrogen.

PTFE also has a very low coefficient of friction, which minimizes wear and heat generation in dynamic applications without requiring lubrication.

The Function of the Energizing Spring

A high-performance metal spring sits inside the PTFE jacket. This spring is the engine of the seal.

It applies a constant, consistent radial force to the sealing lips, pressing them firmly against the hardware surfaces.

This is critical because it compensates for material changes caused by thermal expansion and contraction, seal lip wear over time, and wide pressure fluctuations. Unlike rubber seals, it resists taking a "compression set," ensuring a tight seal for its entire service life.

Key Aerospace Applications and Their Demands

The combination of the PTFE jacket and the energizing spring makes these seals the definitive choice for the most critical systems on an aircraft or spacecraft.

Propulsion and Engine Systems

Applications here include turbine engines, gearbox seals, auxiliary power units (APUs), starters, and alternators.

These systems involve high rotational speeds, with surface velocities from 10-20 m/s to over 100 m/s. The seals must withstand a wide temperature range, often from -53°C to 177°C (-65°F to 350°F), while containing oils and lubricants under pressure.

Fuel and Fluid Management

These seals are essential in fuel pumps, complete fuel systems, and cryogenic propulsion lines.

Their chemical inertness prevents degradation from contact with jet fuel. In cryogenic applications, they remain flexible and effective at temperatures that would make traditional elastomers brittle and useless.

Flight Control and Actuation

You will find them in flap actuators and other hydraulic or pneumatic systems that move the aircraft's control surfaces.

The low-friction nature of PTFE ensures smooth, responsive actuator movement with minimal stick-slip, which is critical for precise flight control. The spring ensures a leak-free seal whether the system is pressurized or at rest.

Environmental and Life Support

In applications like cabin pressure systems and equipment exposed to high altitudes, two properties are paramount.

The seals must perform in near-vacuum conditions without leaking. Furthermore, the PTFE material exhibits very low outgassing, meaning it does not release volatile compounds in a vacuum that could contaminate sensitive optical or electronic equipment.

Understanding the Trade-offs

While incredibly capable, these seals are a specialized solution. Their selection comes with considerations that are important for any design engineer to understand.

Higher Precision Requirements

The relative stiffness of PTFE compared to rubber means it is less forgiving of hardware imperfections.

Mating surfaces must have a fine finish and tight dimensional tolerances to ensure a proper seal, which can increase manufacturing costs.

Installation Sensitivity

Unlike a simple O-ring, spring-energized seals are directional and can be damaged if installed improperly.

Care must be taken during assembly to protect the sealing lips from sharp edges or burrs to prevent nicks that could create a leak path.

Higher Initial Cost

These are advanced, multi-component seals. Their cost is significantly higher than that of simple elastomeric seals.

Their use is justified in applications where the cost of failure—whether in terms of safety, mission success, or equipment damage—is unacceptably high.

Making the Right Choice for Your Goal

Selecting the correct seal requires matching its properties to the specific demands of the application.

- If your primary focus is high-speed rotational sealing: You need a design optimized for engine gearboxes and APUs, focusing on low-friction PTFE compounds and robust spring designs to manage heat and wear.

- If your primary focus is cryogenic fluid handling: Prioritize seals with materials specifically validated for performance at extreme low temperatures, ensuring both the PTFE and spring alloy resist embrittlement.

- If your primary focus is low-friction actuation: Select a seal profile and a light-to-medium force spring to ensure smooth, responsive performance and prevent wear on actuator rods.

- If your primary focus is vacuum or space applications: Specify a PTFE compound with certified low-outgassing data to prevent contamination of nearby sensitive systems.

Ultimately, choosing a PTFE spring-energized seal is a strategic decision to ensure operational integrity under conditions where failure is not an option.

Summary Table:

| Application | Key Demands | Seal Function |

|---|---|---|

| Propulsion & Engine Systems | High speeds, wide temperature range (-65°F to 350°F), pressure fluctuations | Contains oils/lubricants; withstands thermal cycling |

| Fuel & Cryogenic Systems | Chemical resistance, cryogenic temperatures (e.g., liquid oxygen) | Prevents brittleness and degradation; ensures leak-free sealing |

| Flight Control Actuators | Low friction, precise movement, dynamic sealing | Reduces stick-slip; maintains seal under pressure variations |

| Environmental Systems | Vacuum conditions, low outgassing | Prevents contamination; performs in near-vacuum environments |

Need high-performance PTFE seals for your aerospace project? At KINTEK, we specialize in manufacturing precision PTFE components—including custom spring-energized seals—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication from prototypes to high-volume orders ensures reliability in extreme conditions. Contact us today to discuss how our solutions can meet your critical sealing demands!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance