Teflon bushes are most valuable in mechanical assemblies characterized by rotational or sliding movement, especially in applications where low friction, chemical resistance, and wear resistance are critical. They are a definitive solution for machinery like pumps, motors, and conveyor systems, particularly within the automotive, chemical processing, and food manufacturing industries.

The core value of a Teflon bush is not just its application in a specific machine, but its ability to solve the fundamental engineering challenges of friction and corrosion in moving parts, thereby enhancing durability and drastically reducing maintenance requirements.

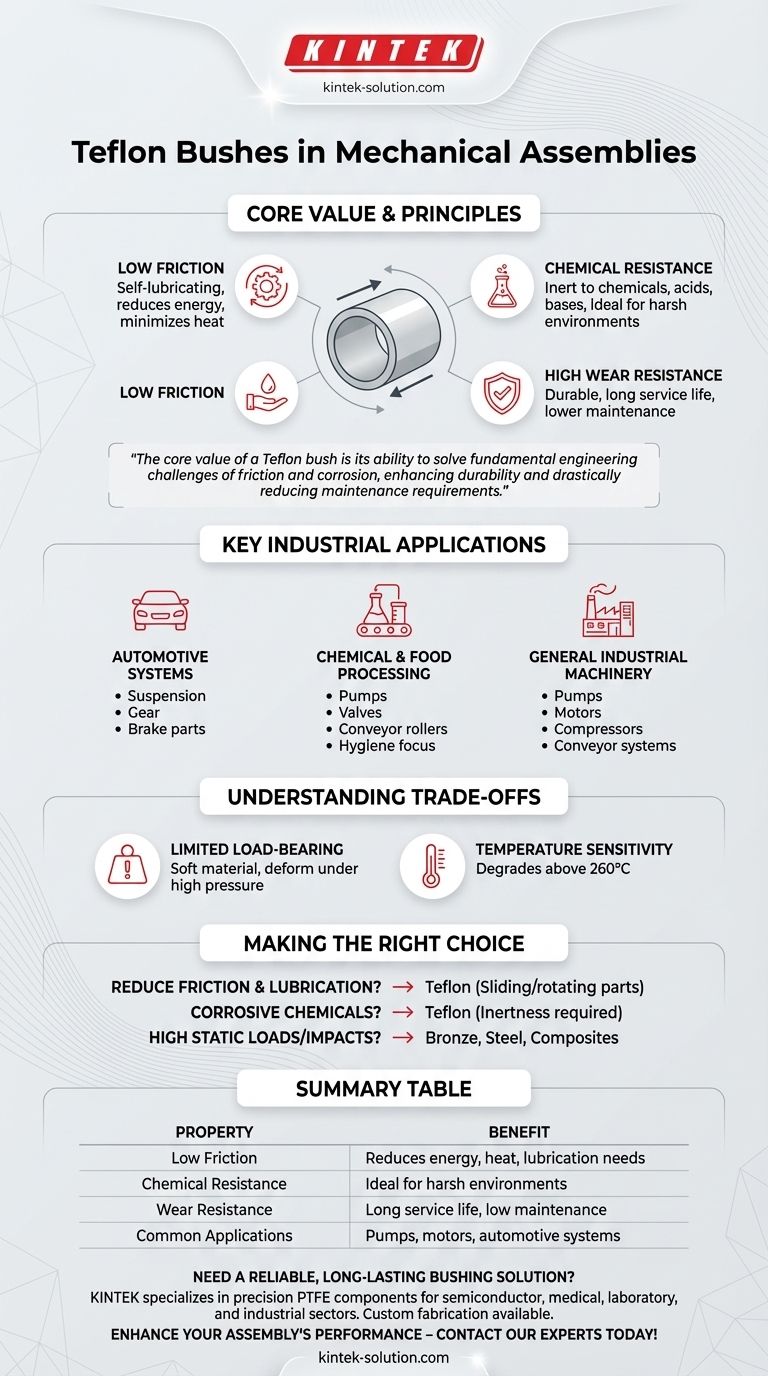

The Core Principles: Why Teflon Excels in Moving Assemblies

To understand where Teflon bushes are most effective, it's essential to focus on their unique material properties. Their value stems from solving specific problems that metal or other polymer bushings cannot handle as effectively.

Exceptionally Low Friction

Teflon (PTFE) has one of the lowest coefficients of friction of any solid material. This property is paramount in assemblies with sliding or rotating components.

This self-lubricating nature reduces the energy needed to operate the machinery, minimizes heat generation, and ensures smooth, consistent motion without the need for external lubricants.

Superior Chemical Resistance

Teflon is almost completely inert and does not react with the vast majority of industrial chemicals, acids, and bases.

This makes Teflon bushes the ideal choice for equipment in chemical processing plants, pharmaceutical manufacturing, or food production, where components are constantly exposed to corrosive or sensitive substances.

High Wear Resistance and Durability

While soft, Teflon is remarkably durable and resistant to wear over millions of cycles. This is crucial for parts that are in constant motion.

In applications like automotive suspension systems or industrial gear assemblies, this durability translates directly to a longer service life for the entire component and significantly lower maintenance costs.

Key Industrial Applications

The combination of these properties makes Teflon bushes a go-to component in several demanding sectors.

Automotive Systems

In the automotive industry, reliability and longevity are non-negotiable. Teflon bushes are used extensively in these areas.

- Suspension Parts: They provide smooth, quiet movement and resist degradation from road salt and moisture.

- Gear Systems: Their low-friction surface reduces wear on moving parts.

- Brake Systems: They offer consistent performance and resistance to brake fluid and high temperatures.

Chemical and Food Processing

Hygiene and resistance to corrosion are the primary concerns in these industries.

Teflon's inertness ensures it won't contaminate products or degrade when exposed to cleaning agents and caustic materials, making it perfect for pumps, valves, and conveyor rollers.

General Industrial Machinery

The foundational use for Teflon bushes is in a wide range of industrial equipment where reliability is key.

This includes pumps, motors, compressors, and conveyor systems, where the common challenge is maintaining smooth rotational or sliding movement with minimal upkeep over a long operational life.

Understanding the Trade-offs

No material is perfect for every situation. Being an effective advisor means acknowledging the limitations of Teflon to ensure it is used in the right context.

Limited Load-Bearing Capacity

Compared to metal bearings like bronze or steel, pure Teflon is a relatively soft material. It can deform or "creep" under very high, constant pressure.

For extremely high-load applications, a composite or metal bearing may be a more suitable choice.

Temperature Sensitivity

While Teflon performs well across a wide range of temperatures, it is not intended for high-temperature applications where ceramics or specific metal alloys would be required. Its properties can begin to degrade at temperatures above 260°C (500°F).

Making the Right Choice for Your Assembly

Your decision should be driven entirely by the specific operational environment and performance demands of your mechanical assembly.

- If your primary focus is reducing friction and eliminating the need for lubrication: Teflon is one of the best solutions available for sliding and rotating parts.

- If your assembly is exposed to corrosive chemicals, moisture, or sensitive materials: Teflon's chemical inertness makes it the superior and often necessary choice.

- If your assembly must withstand extremely high static loads, impacts, or high temperatures: You should evaluate harder materials like bronze, steel, or specialized composite bearings.

Ultimately, choosing the right bushing material is about matching the unique strengths of the material to the specific challenges of your application.

Summary Table:

| Key Property | Benefit for Mechanical Assemblies |

|---|---|

| Low Friction | Reduces energy use, heat, and need for lubrication in rotating/sliding parts. |

| Chemical Resistance | Ideal for harsh environments like chemical processing and food manufacturing. |

| Wear Resistance | Provides long service life and lower maintenance in high-cycle applications. |

| Common Applications | Pumps, motors, conveyor systems, automotive suspension, and brake systems. |

Need a reliable, long-lasting bushing solution for your mechanical assembly?

At KINTEK, we specialize in manufacturing precision PTFE components like seals, liners, and custom labware. Our expertise is invaluable for industries where low friction, chemical resistance, and durability are critical—including semiconductor, medical, laboratory, and industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your specific application challenges.

Enhance your assembly's performance and reduce maintenance—contact our experts today to discuss your project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs