In short, medical-grade PTFE liners are most commonly used in devices that navigate the human body or require extreme chemical resistance and biocompatibility. Key applications include catheters, endoscopes, guidewires, and vascular grafts, where the material's unique properties enhance performance and patient safety.

The core reason for PTFE's widespread medical use is not just one feature, but its unique combination of extreme lubricity (low friction), chemical inertness, and biocompatibility. This trifecta makes it the default choice for devices that must move smoothly within the body without causing adverse reactions or degrading over time.

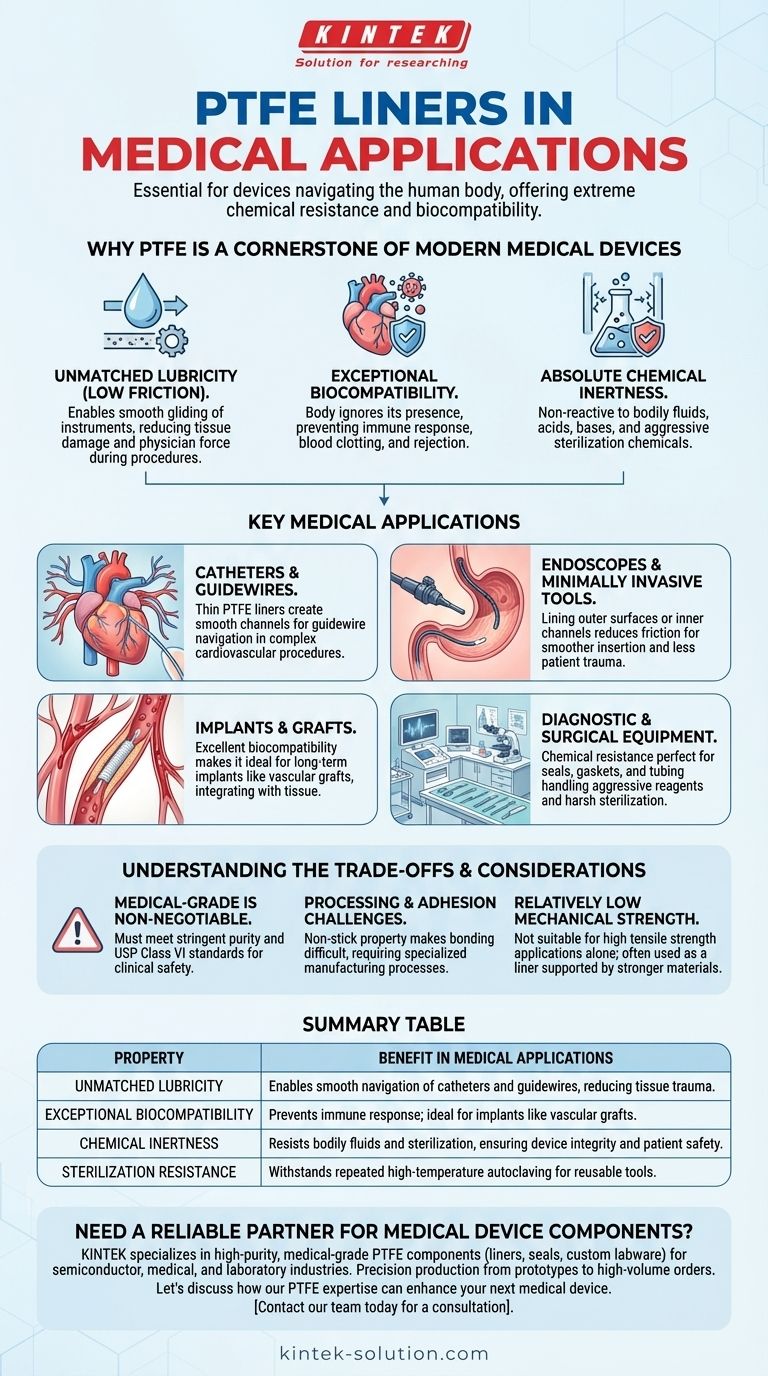

Why PTFE is a Cornerstone of Modern Medical Devices

To understand PTFE's role, you must first understand its fundamental properties. The material's value in medicine is not arbitrary; it is a direct result of its molecular structure, which gives it a set of highly desirable characteristics for interacting with the human body.

Unmatched Lubricity (Low Coefficient of Friction)

The most famous property of PTFE is its slipperiness. In medical devices, this is not a convenience—it is a critical safety and performance feature.

A PTFE liner allows instruments to glide through blood vessels, urinary tracts, or other internal pathways with minimal resistance. This reduces the force a physician needs to apply, lowers the risk of tissue damage, and provides better control and tactile feedback during delicate procedures.

Exceptional Biocompatibility

Biocompatibility means the material does not provoke an immune response or toxic reaction when introduced to the body. Medical-grade PTFE is highly biocompatible.

The human body largely ignores its presence, making it an ideal candidate for both short-term devices and long-term implants. This prevents complications like inflammation, blood clotting, and tissue rejection.

Absolute Chemical Inertness

PTFE is one of the most non-reactive substances known. It does not react with bodily fluids, acids, or bases.

This inertness ensures that the liner will not degrade or leach harmful substances into the patient's system. It also means the device can withstand aggressive cleaning and sterilization chemicals between uses without compromising its integrity.

Key Medical Applications in Detail

These core properties translate directly into specific, high-stakes medical applications where performance cannot be compromised.

Catheters and Guidewires

This is the most common application. A thin PTFE liner inside a catheter creates an incredibly smooth channel for a guidewire or other instruments to pass through. This is essential for navigating the complex and delicate network of blood vessels during cardiovascular procedures.

Endoscopes and Minimally Invasive Tools

The outer surfaces of endoscopes or the inner channels of surgical instruments are often lined with PTFE. This reduces friction as the device is inserted and maneuvered, making the procedure smoother for the surgeon and less traumatic for the patient.

Implants and Grafts

Because of its excellent biocompatibility, PTFE is used to create medical implants like vascular grafts. These artificial blood vessels are used to bypass blocked arteries. The body tolerates the material, allowing tissue to integrate with the graft over time.

Diagnostic and Surgical Equipment

Beyond patient-contacting devices, PTFE is used for critical components within medical equipment. Its chemical resistance makes it perfect for seals, gaskets, and tubing that handle aggressive reagents or require frequent, harsh sterilization.

Understanding the Trade-offs and Considerations

While highly effective, PTFE is not a universal solution. A clear-eyed technical assessment requires understanding its limitations.

Medical-Grade is Non-Negotiable

The PTFE used in cookware or industrial seals is not the same as that used in medical devices. Medical-grade PTFE must meet stringent purity and biocompatibility standards, such as USP Class VI, to be considered safe for clinical use.

Processing and Adhesion Challenges

The same non-stick property that makes PTFE so valuable also makes it extremely difficult to bond to other materials. Attaching a PTFE liner to a different polymer or metal substrate requires specialized manufacturing processes, which can add complexity and cost to device design.

Relatively Low Mechanical Strength

Compared to metals or other high-strength polymers, PTFE is a relatively soft material. It is not suitable for applications requiring high tensile strength or abrasion resistance on its own. Device designs must account for this, often using PTFE as a liner or coating supported by a stronger structural material.

Making the Right Choice for Your Application

Your choice of material should always be driven by the primary functional demand of the medical device.

- If your primary focus is maneuverability in tortuous pathways (e.g., catheters, endoscopes): PTFE's unparalleled lubricity is the most critical property to leverage.

- If your primary focus is long-term implantation (e.g., vascular grafts): PTFE's proven biocompatibility and chemical inertness are essential for ensuring patient safety and device stability.

- If your primary focus is device durability and reusability (e.g., surgical tools): PTFE's resistance to high-temperature sterilization and harsh chemicals makes it a reliable choice.

By understanding these core principles, you can confidently specify PTFE where its unique strengths will directly lead to a safer, more effective medical device.

Summary Table:

| Property | Benefit in Medical Applications |

|---|---|

| Unmatched Lubricity | Enables smooth navigation of catheters and guidewires, reducing tissue trauma. |

| Exceptional Biocompatibility | Prevents immune response; ideal for implants like vascular grafts. |

| Chemical Inertness | Resists bodily fluids and sterilization, ensuring device integrity and patient safety. |

| Sterilization Resistance | Withstands repeated high-temperature autoclaving for reusable tools. |

Need a reliable partner for your medical device components?

At KINTEK, we specialize in manufacturing high-purity, medical-grade PTFE components—including liners, seals, and custom labware—for the semiconductor, medical, and laboratory industries. Our precision production and custom fabrication services, from prototypes to high-volume orders, ensure your devices meet the highest standards for performance and patient safety.

Let's discuss how our PTFE expertise can enhance your next medical device. Contact our team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance