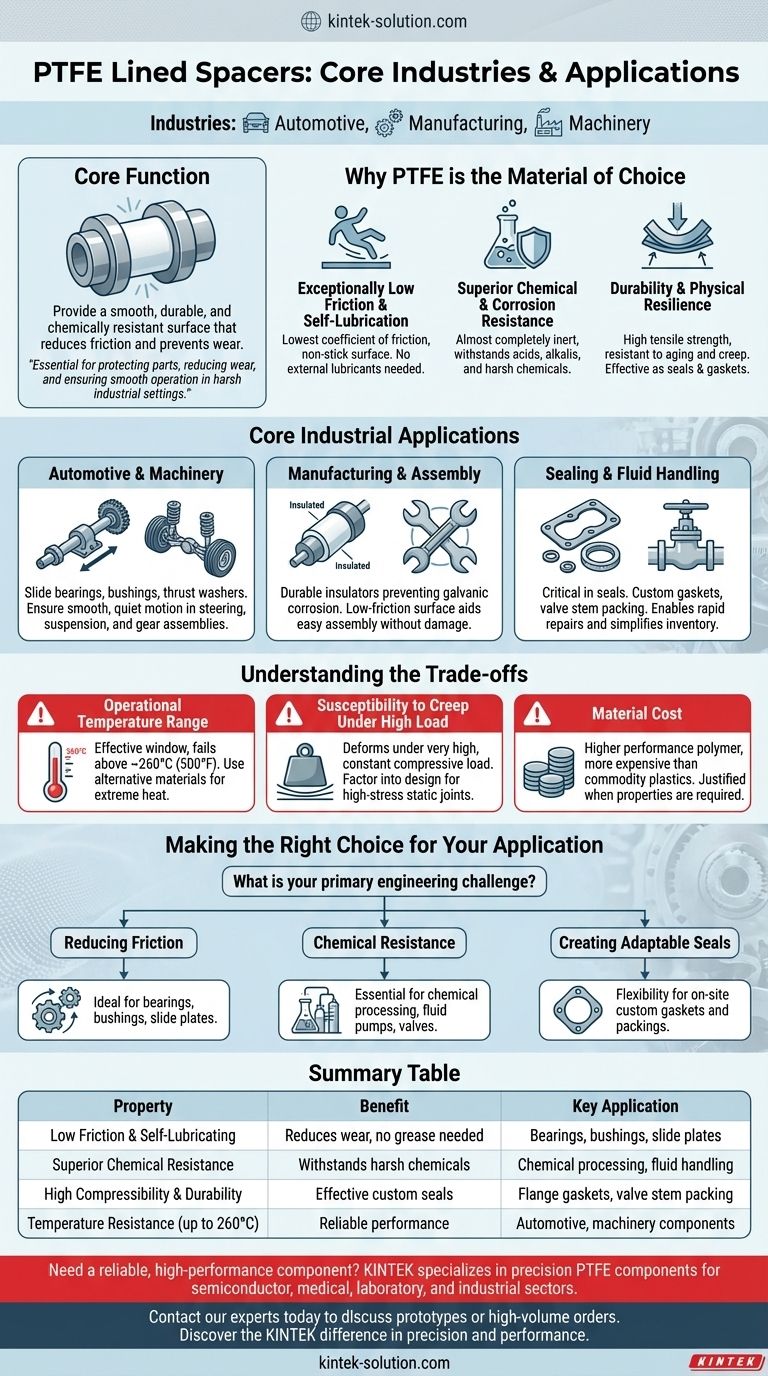

PTFE Lined Spacers are primarily used in the automotive, manufacturing, and machinery industries. Their core function is to provide a smooth, durable, and chemically resistant surface that reduces friction and prevents wear between critical components, ensuring longevity and reliable performance in demanding operational environments.

The value of a PTFE Lined Spacer extends beyond simple spacing. Its true utility comes from the exceptional properties of PTFE itself—namely, its extremely low friction, chemical inertness, and durability—making it an essential component for protecting parts, reducing wear, and ensuring smooth operation in harsh industrial settings.

Why PTFE is the Material of Choice

The versatility of these spacers comes directly from the unique characteristics of Polytetrafluoroethylene (PTFE), the material they are made from. Understanding these properties is key to knowing where and why to use them.

Exceptionally Low Friction and Self-Lubrication

PTFE has one of the lowest coefficients of friction of any known solid. This creates an incredibly smooth, non-stick surface.

This self-lubricating property means that components can slide or rotate against the spacer with minimal resistance and without the need for external lubricants like grease, which can attract contaminants.

Superior Chemical and Corrosion Resistance

PTFE is almost completely inert, meaning it does not react with most chemicals.

It demonstrates excellent resistance to both acids and alkalis, making it an ideal choice for applications involving corrosive fluids or harsh cleaning agents.

Durability and Physical Resilience

These spacers possess high tensile strength and resistance to aging, meaning they won't become brittle or degrade over time from environmental exposure.

Their high compressibility and resistance to creep (the tendency to slowly deform under a constant load) allow them to function effectively as seals and gaskets.

Core Industrial Applications

The combination of these properties makes PTFE spacers a problem-solver in several key areas.

Automotive and Machinery

In automotive systems and general machinery, these spacers are used as slide bearings, bushings, and thrust washers.

They are placed between moving parts in steering columns, suspension systems, and gear assemblies to ensure smooth, quiet motion and prevent metal-on-metal wear.

Manufacturing and Assembly

During assembly, PTFE spacers act as durable insulators between different materials, preventing galvanic corrosion.

Their low-friction surface also aids in the assembly process itself, allowing parts to be fitted together more easily without damage.

Sealing and Fluid Handling

This is a critical application where PTFE excels. Due to its flexibility and compressibility, it is used extensively in the seal industry.

It can be formed on-site into custom gaskets for flanges or used as valve stem packing. This adaptability eliminates the need to stock hundreds of pre-sized seals, simplifying inventory and enabling rapid repairs.

Understanding the Trade-offs

While highly effective, PTFE spacers are not a universal solution. An objective assessment requires acknowledging their limitations.

Operational Temperature Range

PTFE performs exceptionally well within a specific temperature window but can fail in extreme heat. For applications exceeding approximately 260°C (500°F), alternative materials like graphite or certain metals must be considered.

Susceptibility to Creep Under High Load

While PTFE has good creep resistance for a polymer, it can still deform over time if subjected to a very high, constant compressive load. This must be factored into the design calculations for high-stress static joints.

Material Cost

PTFE is a high-performance polymer and is typically more expensive than commodity plastics like nylon or polyethylene. Its use is justified when its specific properties—low friction, chemical resistance—are a requirement, not just a preference.

Making the Right Choice for Your Application

To select the right component, match your primary engineering challenge to the spacer's core strengths.

- If your primary focus is reducing friction in a moving assembly: The self-lubricating nature of PTFE makes it ideal for bearings, bushings, and slide plates where smooth motion is critical.

- If your primary focus is chemical resistance: PTFE's inertness is essential for components used in chemical processing plants, fluid pumps, and industrial valves.

- If your primary focus is creating adaptable seals: Its unique combination of flexibility and compressibility allows for the on-site fabrication of gaskets and valve packings, reducing inventory and maintenance downtime.

By understanding the fundamental properties of PTFE, you can leverage these spacers not just as fillers, but as active problem-solving components in your designs.

Summary Table:

| Property | Benefit | Key Application |

|---|---|---|

| Low Friction & Self-Lubricating | Reduces wear, eliminates need for grease | Bearings, bushings, slide plates |

| Superior Chemical Resistance | Withstands harsh acids, alkalis, and cleaners | Chemical processing, fluid handling |

| High Compressibility & Durability | Creates effective, on-site custom seals | Flange gaskets, valve stem packing |

| Temperature Resistance (up to 260°C/500°F) | Reliable performance in demanding environments | Automotive, machinery components |

Need a reliable, high-performance component for your application?

KINTEK specializes in manufacturing precision PTFE components, including seals, liners, and custom spacers, for the semiconductor, medical, laboratory, and industrial sectors. We can help you leverage the unique properties of PTFE to solve your specific challenges with friction, corrosion, and wear.

Contact our experts today to discuss your requirements for prototypes or high-volume orders and discover the KINTEK difference in precision and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry