In short, PTFE instrumentation tube fittings are predominantly used in industries where fluid purity and resistance to aggressive chemicals are non-negotiable. These include chemical processing, semiconductor manufacturing, medical and pharmaceutical labs, food and beverage production, and aerospace applications.

The selection of PTFE is not arbitrary; it is a deliberate engineering choice driven by the material's unique ability to handle corrosive substances, maintain extreme purity, and withstand wide temperature ranges where other materials would fail.

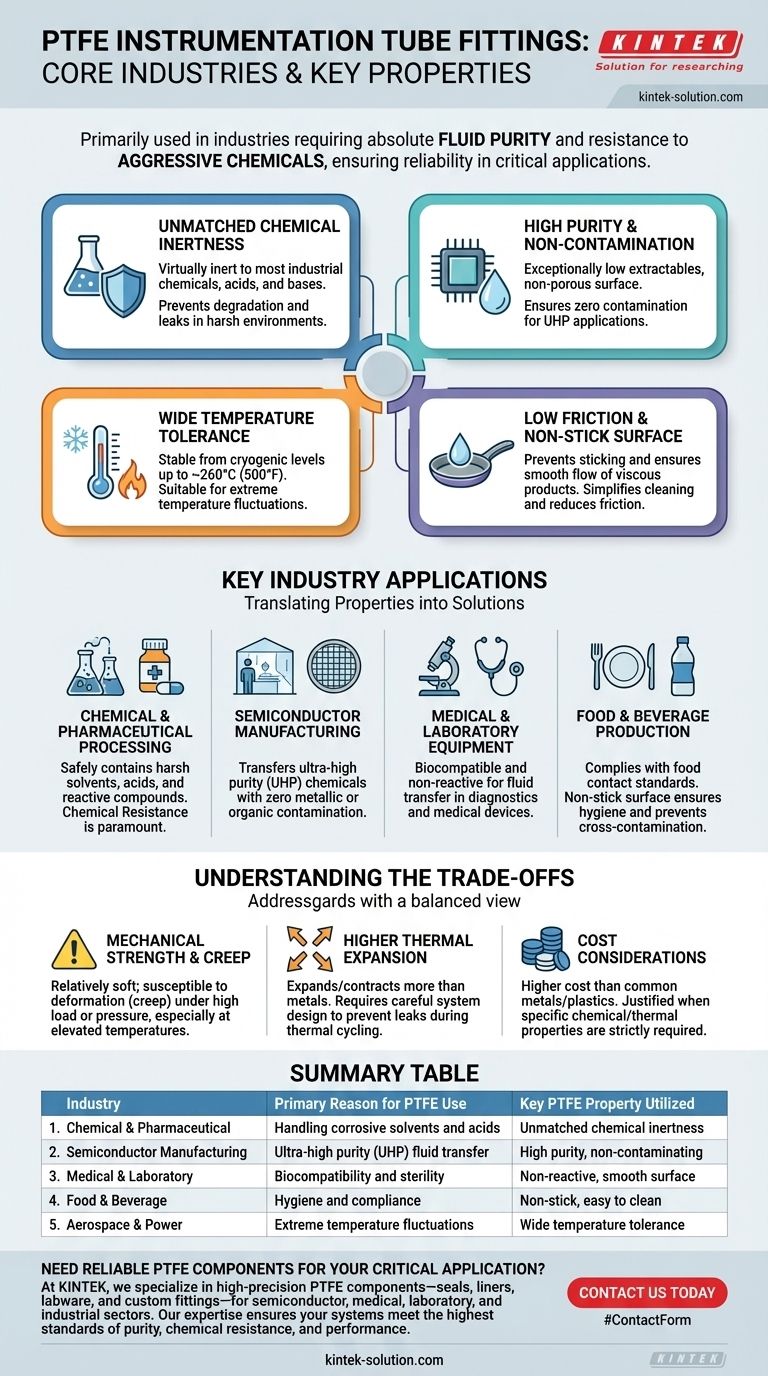

The Core Properties Driving PTFE Adoption

The widespread use of Polytetrafluoroethylene (PTFE) in demanding industries stems from a specific set of material characteristics. Understanding these properties explains why it's the material of choice for critical applications.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, acids, and bases. This makes it the default choice for transferring aggressive or corrosive fluids that would degrade metal or other polymer components.

This property is critical in chemical processing, pharmaceutical manufacturing, and oil and gas, ensuring the integrity of the fluid handling system and preventing dangerous leaks.

High Purity and Non-Contamination

The material has an exceptionally low level of extractables, meaning it does not leach contaminants into the fluids it carries. Its surface is also incredibly smooth and non-porous.

This is an absolute requirement in the semiconductor industry, where even trace impurities can ruin microchips, and in medical applications, where patient safety depends on sterile, non-reactive fluid paths.

Wide Temperature Tolerance

PTFE maintains its properties across a vast temperature spectrum, from cryogenic levels up to approximately 260°C (500°F).

This stability makes it suitable for applications in aerospace, power plants, and chemical reactors that experience extreme temperature fluctuations.

Low Friction and Non-Stick Surface

Famously used for non-stick coatings, PTFE's low coefficient of friction prevents media from sticking to its surface.

In food and beverage processing, this ensures the smooth flow of viscous products and simplifies cleaning. In manufacturing, it reduces friction in moving parts.

A Closer Look at Key Industry Applications

These core properties translate directly into solutions for specific industrial challenges.

Chemical and Pharmaceutical Processing

In these sectors, fittings must reliably contain harsh solvents, strong acids, and reactive compounds without corroding or contaminating the final product. PTFE's chemical resistance is paramount.

Semiconductor Manufacturing

The production of microchips requires the transfer of ultra-high purity (UHP) chemicals. PTFE fittings ensure that the fluid delivery system introduces zero metallic or organic contamination to the process.

Medical and Laboratory Equipment

Biocompatibility and sterility are key. PTFE is used for fluid transfer in diagnostic equipment and medical devices because it does not react with biological samples or sterilization chemicals.

Food and Beverage

PTFE components comply with regulatory standards for food contact. Their non-stick nature prevents residue buildup, which is crucial for hygiene and preventing batch-to-batch cross-contamination.

Understanding the Trade-offs

While powerful, PTFE is not a universal solution. An objective assessment requires acknowledging its limitations.

Mechanical Strength and Creep

PTFE is a relatively soft material compared to metals like stainless steel. Under high mechanical load or sustained pressure, especially at elevated temperatures, it can be susceptible to "creep," or gradual deformation.

Higher Thermal Expansion

The material expands and contracts with temperature changes more significantly than metals. This must be accounted for in system design to prevent leaks at connection points during thermal cycling.

Cost Considerations

High-performance PTFE fittings are typically more expensive than those made from common metals or other plastics. Their use is justified when their specific chemical and thermal properties are a strict requirement.

Making the Right Choice for Your Application

Selecting the correct material is about matching its properties to the demands of your specific environment.

- If your primary focus is handling aggressive chemicals or high-purity fluids: PTFE's inertness and non-leaching properties make it the superior and often necessary choice.

- If your primary focus is high structural pressure or mechanical rigidity: A metal fitting, such as 316 stainless steel, is likely the more appropriate solution.

- If your primary focus is general-purpose fluid transfer at moderate temperatures: Less expensive polymers or metals may provide a more economical and perfectly adequate solution.

Ultimately, choosing PTFE is an investment in reliability and safety for applications where material failure is not an option.

Summary Table:

| Industry | Primary Reason for PTFE Use | Key PTFE Property Utilized |

|---|---|---|

| Chemical & Pharmaceutical | Handling corrosive solvents and acids | Unmatched chemical inertness |

| Semiconductor Manufacturing | Ultra-high purity (UHP) fluid transfer | High purity, non-contaminating |

| Medical & Laboratory | Biocompatibility and sterility | Non-reactive, smooth surface |

| Food & Beverage | Hygiene and compliance | Non-stick, easy to clean |

| Aerospace & Power | Extreme temperature fluctuations | Wide temperature tolerance |

Need reliable PTFE components for your critical application?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, labware, and custom instrumentation fittings—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume production, our expertise ensures your systems meet the highest standards of purity, chemical resistance, and performance.

Contact us today to discuss your specific needs and let our solutions enhance the safety and reliability of your operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications