From non-stick pans to aerospace components, Polytetrafluoroethylene (PTFE) is one of the most versatile engineering polymers available. Its applications are exceptionally broad, spanning industries that require extreme chemical resistance, very low friction, high-temperature stability, or superior electrical insulation. Common uses include high-performance seals and gaskets, low-friction bearings, coatings for cookware and industrial equipment, and insulation for critical wiring.

PTFE’s value comes not from a single attribute, but from its unique combination of properties. Understanding how its chemical inertness, low friction, and thermal stability work together is the key to recognizing why it is an essential problem-solving material across so many fields.

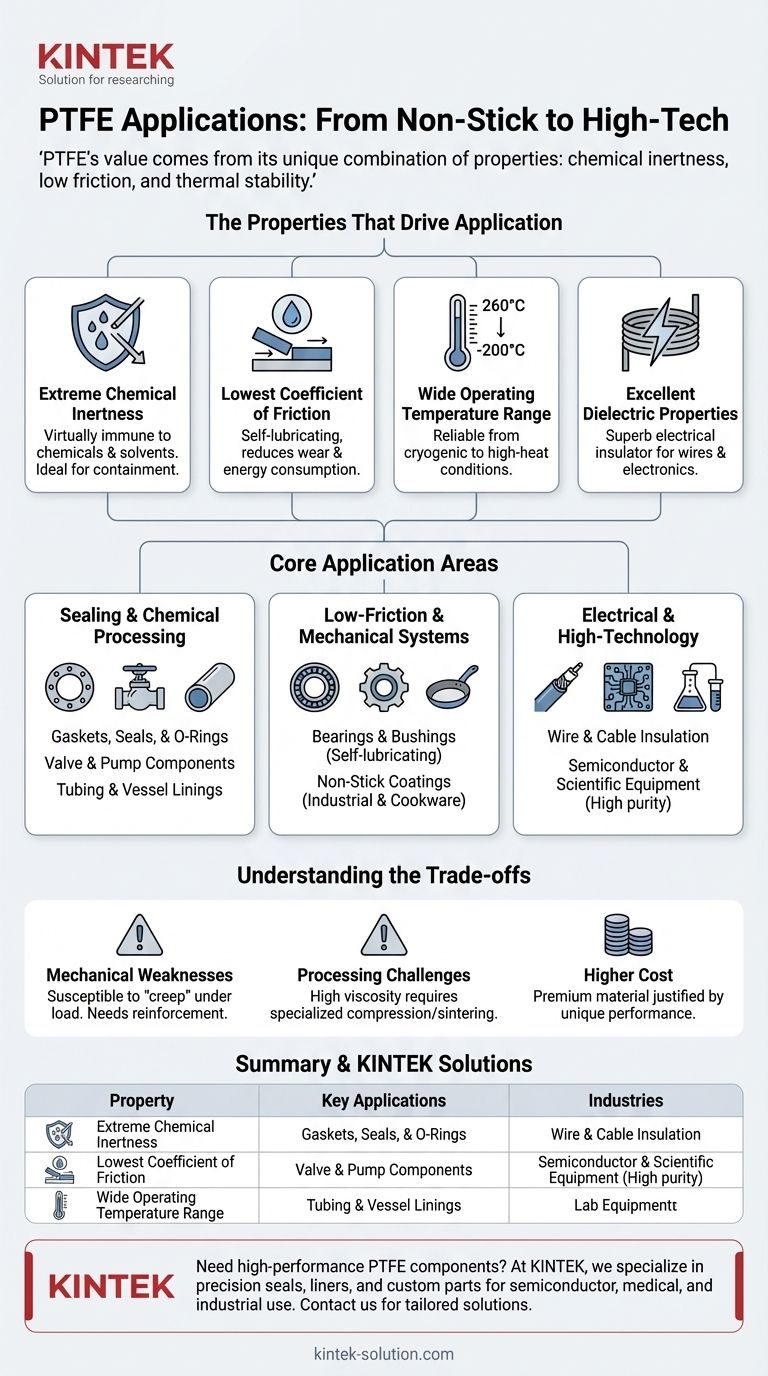

The Properties That Drive Application

Before listing its uses, it's critical to understand the core properties that make PTFE so valuable. An application is simply a problem that one of these properties solves.

Extreme Chemical Inertness

PTFE is virtually immune to attack by almost all chemicals, solvents, and corrosive agents. This makes it an ideal material for containing or transporting aggressive substances without degrading or contaminating them.

The Lowest Coefficient of Friction

Known for having one of the lowest coefficients of friction of any solid, PTFE allows surfaces to slide against each other with minimal resistance. This property makes it self-lubricating, reducing wear and energy consumption in mechanical systems.

Wide Operating Temperature Range

PTFE performs reliably across an exceptionally wide temperature range, from cryogenic conditions (-200°C / -328°F) up to high-heat applications (260°C / 500°F). It maintains its properties where many other materials would become brittle or melt.

Excellent Dielectric Properties

PTFE is a superb electrical insulator with a very high dielectric strength. It does not conduct electricity, making it perfect for insulating wires, cables, and sensitive electronic components, especially at high frequencies.

Core Application Areas

These properties translate directly into specific, high-value applications across multiple industries.

Sealing and Chemical Processing

This is arguably PTFE's most common industrial use, directly leveraging its chemical inertness and durability.

Gaskets, Seals, and O-Rings

Because it doesn't degrade when exposed to harsh chemicals, PTFE is used to create durable seals that prevent leaks in chemical processing, oil and gas, and pharmaceutical manufacturing.

Valve and Pump Components

Components like valve seats, pump diaphragms, and manifolds made from PTFE resist corrosion and prevent "stick-slip" behavior due to their low friction, ensuring smooth and reliable operation.

Tubing and Vessel Linings

PTFE is used to line pipes, tanks, and chemical reactors. This protects the structural vessel from corrosion and prevents the chemical contents from being contaminated by the vessel material.

Low-Friction and Mechanical Systems

PTFE's exceptionally low friction is the key driver for its use in mechanical and moving parts.

Bearings and Bushings

"Bearing grade" PTFE, often filled with materials like glass or bronze for added strength, is used for self-lubricating bearings. They are ideal for applications where traditional lubricants are impractical or would attract contaminants.

Non-Stick Coatings

The most famous application is non-stick cookware. The same principle is applied to industrial conveyor belts, rollers, and processing equipment to prevent sticky materials from building up and disrupting production.

Electrical and High-Technology

PTFE's combination of thermal stability and high-purity electrical insulation makes it essential for demanding electronics.

Wire and Cable Insulation

Its high dielectric strength and heat resistance make it a premium insulator for coaxial cables, data wiring, and aerospace applications where signal integrity and fire safety are critical.

Semiconductor and Scientific Equipment

In semiconductor manufacturing, purity is paramount. PTFE is used for fluid handling components because it does not leach contaminants. Its inertness also makes it a staple for lab equipment exposed to various chemicals.

Understanding the Trade-offs

No material is perfect. Acknowledging PTFE's limitations is key to using it correctly.

Mechanical Weaknesses

Pure PTFE is relatively soft and can be prone to "creep"—deforming slowly over time under a constant load. For structural applications, it must be reinforced with fillers like glass fiber, carbon, or bronze to improve its strength and wear resistance.

Processing Challenges

PTFE has an extremely high melting viscosity, meaning it cannot be processed using conventional melt techniques like injection molding. Instead, it must be formed through more complex and costly compression and sintering processes, similar to powdered metallurgy.

Higher Cost

Compared to common polymers like polyethylene or polypropylene, PTFE is a premium material. Its cost is justified by its unique performance in environments where other plastics would fail immediately.

Making the Right Choice for Your Application

Selecting a material is about matching its strengths to your primary goal.

- If your primary focus is preventing chemical corrosion: PTFE is an industry standard for seals, gaskets, and linings in aggressive fluid handling environments.

- If your primary focus is reducing friction and wear: PTFE bearings and coatings offer self-lubricating performance where traditional lubricants would fail or cause contamination.

- If your primary focus is high-performance electrical insulation: Its superior dielectric strength and thermal stability make PTFE a prime choice for critical wiring and electronic components.

- If your primary focus is food or medical safety: Its inertness and biocompatibility make it a trusted material for everything from conveyor belts to catheters.

Understanding these core strengths allows you to deploy PTFE not just as a material, but as a targeted engineering solution.

Summary Table:

| Property | Key Applications | Industries Benefited |

|---|---|---|

| Extreme Chemical Inertness | Seals, gaskets, linings, tubing | Chemical processing, pharmaceuticals, oil & gas |

| Lowest Coefficient of Friction | Bearings, bushings, non-stick coatings | Food processing, manufacturing, automotive |

| Wide Temperature Range | High-heat/cryogenic seals, insulation | Aerospace, semiconductor, energy |

| Excellent Dielectric Properties | Wire insulation, electronic components | Electronics, telecommunications, medical |

Need high-performance PTFE components tailored to your industry? At KINTEK, we specialize in manufacturing precision PTFE seals, liners, labware, and custom components for semiconductor, medical, laboratory, and industrial applications. Whether you require prototypes or high-volume orders, our expertise ensures superior chemical resistance, low friction, and thermal stability for your most demanding environments. Contact us today to discuss your specific needs and discover how our PTFE solutions can enhance your product performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is notable about the coefficient of friction of PTFE? Achieve Unmatched Low-Friction Performance

- Is PTFE a thermoplastic or thermoset material? Unpacking Its Unique Polymer Properties

- What is Teflon/PTFE and what are its key characteristics? Unlock the Power of a High-Performance Polymer

- What are bronze bushings made of? Discover the Copper-Tin Alloy for Superior Performance

- What are common uses of PTFE? Unlock Versatility for Your Industry

- What makes PTFE plastic uniquely versatile across industries? The 4 Key Properties Explained

- In which industries is Teflon commonly used? Essential for Chemical, Medical, and Aerospace

- What are the advantages of PTFE? Unlock Unmatched Chemical & Thermal Stability