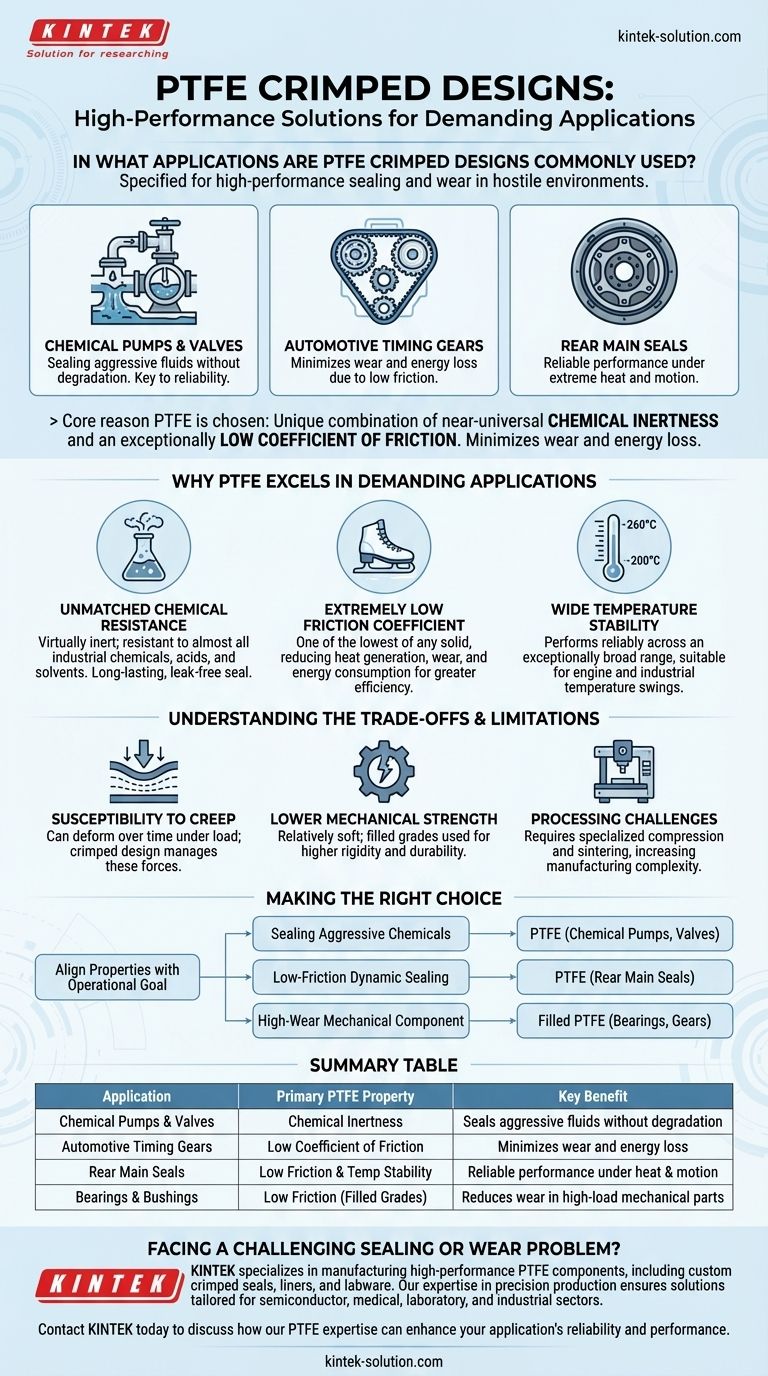

In short, PTFE crimped designs are specified for high-performance sealing and wear applications where environmental hostility and low friction are critical. They are most commonly used in components like chemical pumps, automotive timing gears, and rear main seals that must operate reliably under extreme chemical exposure, temperature ranges, and mechanical stress.

The core reason PTFE is chosen for these demanding roles is its unique combination of near-universal chemical inertness and an exceptionally low coefficient of friction. This makes it one of the few materials that can effectively seal aggressive chemicals while simultaneously minimizing wear and energy loss in moving parts.

Why PTFE Excels in Demanding Applications

The use of PTFE in critical components is not accidental; it stems directly from a set of powerful material properties that solve fundamental engineering problems.

Unmatched Chemical Resistance

PTFE is virtually inert and resistant to almost all industrial chemicals, acids, and solvents. This property is the primary reason it is specified for chemical pumps and seals handling aggressive fluids.

Where other elastomers or plastics would degrade and fail, PTFE maintains its structural integrity, ensuring a long-lasting, leak-free seal.

Extremely Low Friction Coefficient

PTFE has one of the lowest coefficients of friction of any known solid, often compared to wet ice on wet ice. This "slipperiness" is essential for dynamic applications like rear main seals and timing gears.

This property minimizes heat generation, reduces wear on mating surfaces, and decreases the energy required to operate the system, leading to greater efficiency and component longevity.

Wide Temperature Stability

PTFE performs reliably across an exceptionally broad temperature range, from cryogenic conditions (-200°C) up to high-heat environments (260°C).

This makes it suitable for engine components that experience significant temperature swings and for industrial equipment operating in extreme processing conditions.

Excellent Electrical Insulation

While less critical for pumps or gears, PTFE's outstanding properties as an electrical insulator make it a top choice for wire insulation and components in transformers and printed circuit boards, especially where high temperatures are also a factor.

Understanding the Trade-offs and Limitations

No material is perfect. Acknowledging the limitations of PTFE is crucial for successful application design and avoiding premature failure.

Susceptibility to Creep

A key weakness of PTFE is its tendency to "creep" or cold-flow. Under a constant compressive load, the material can slowly deform over time.

This must be accounted for in the design of gaskets and seals to ensure that sealing pressure is maintained throughout the component's service life. The "crimped" design itself is often a strategy to manage these forces.

Lower Mechanical Strength

Compared to engineering plastics like PEEK or Nylon, unfilled PTFE is relatively soft and has lower tensile strength and wear resistance.

For applications requiring greater rigidity and durability, such as bearings or high-load gears, filled grades of PTFE are used. These grades incorporate materials like glass fiber, carbon, or bronze to significantly improve mechanical properties.

Processing Challenges

PTFE has an extremely high melt viscosity, which means it cannot be processed using conventional melt-extrusion or injection molding techniques.

Instead, it requires specialized compression and sintering processes, which can increase the cost and complexity of manufacturing components.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with your primary operational goal.

- If your primary focus is sealing aggressive chemicals: PTFE is the default choice due to its near-universal inertness, making it ideal for chemical processing pumps, valves, and transport systems.

- If your primary focus is low-friction dynamic sealing: The exceptionally low coefficient of friction makes PTFE ideal for rotating seals, like an engine's rear main seal, where minimizing drag and wear is critical.

- If your primary focus is a high-wear mechanical component: Consider a filled grade of PTFE to gain the necessary wear resistance and strength for parts like bearings, bushings, and gears.

By understanding both its powerful advantages and its inherent limitations, you can effectively leverage PTFE for your most critical engineering challenges.

Summary Table:

| Application | Primary PTFE Property Utilized | Key Benefit |

|---|---|---|

| Chemical Pumps & Valves | Chemical Inertness | Seals aggressive fluids without degradation |

| Automotive Timing Gears | Low Coefficient of Friction | Minimizes wear and energy loss |

| Rear Main Seals | Low Friction & Temperature Stability | Reliable performance under heat and motion |

| Bearings & Bushings | Low Friction (Filled Grades) | Reduces wear in high-load mechanical parts |

Facing a challenging sealing or wear problem? KINTEK specializes in manufacturing high-performance PTFE components, including custom crimped seals, liners, and labware. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you get a solution tailored for the demanding environments of the semiconductor, medical, laboratory, and industrial sectors.

Contact KINTEK today to discuss how our PTFE expertise can enhance your application's reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection