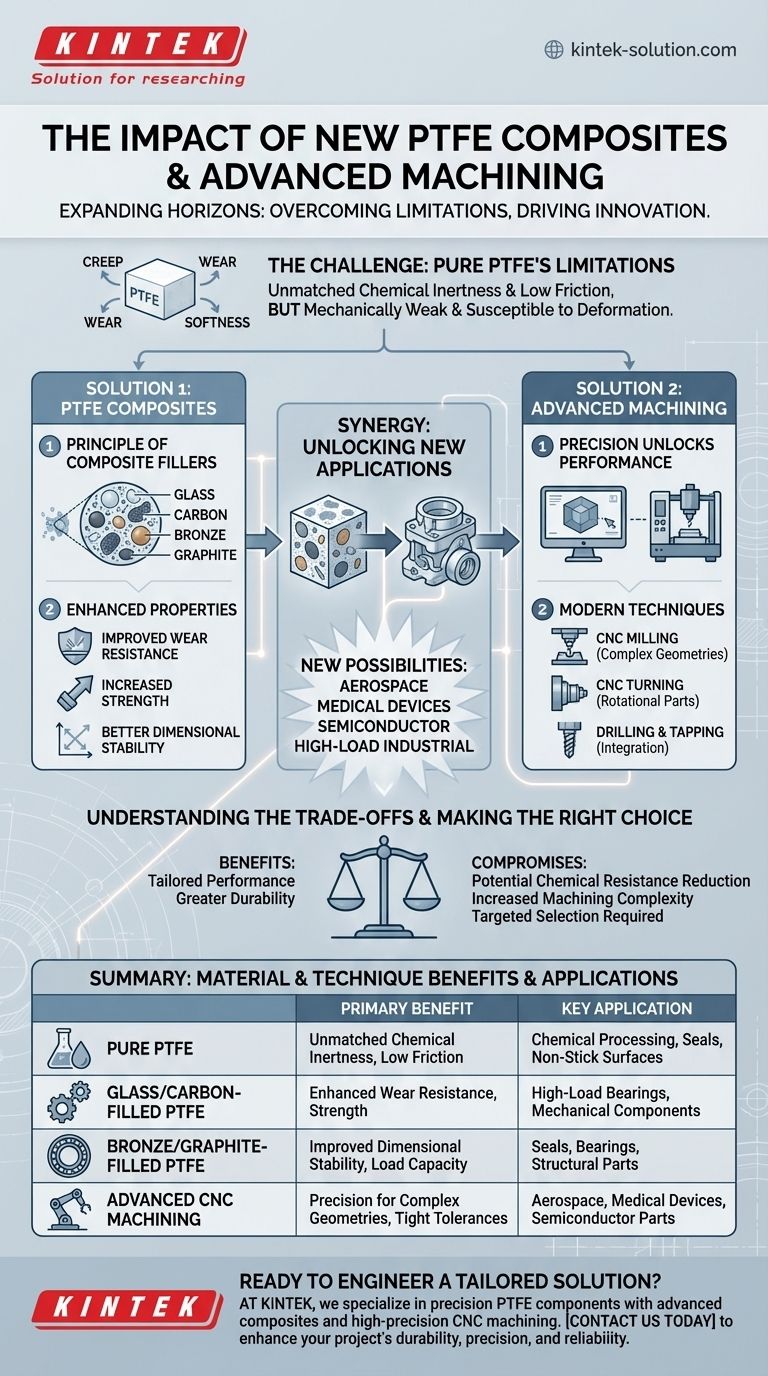

To be direct, new PTFE composites and advanced machining techniques are fundamentally expanding where and how high-performance components can be used. This evolution allows for the creation of more durable, precise, and specialized parts, driving innovation across demanding sectors by overcoming the traditional limitations of pure Polytetrafluoroethylene (PTFE).

The core impact is not just about making better versions of existing parts. It's about enabling entirely new applications by systematically engineering solutions to the inherent weaknesses of pure PTFE, such as its softness and poor wear resistance, through material science and precision manufacturing.

The Foundation: Why Pure PTFE Is Essential

Before understanding the impact of new developments, we must recognize the core properties that make PTFE, commonly known by the brand name Teflon, so valuable.

Unmatched Chemical Inertness

Pure PTFE is exceptionally resistant to nearly all industrial chemicals and solvents. This makes it a critical material for lining tanks, pipes, and valves in chemical processing plants, where it protects equipment from corrosion and failure.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This "non-stick" quality is essential for creating self-lubricating bearings, seals, and other components where reducing friction and wear is paramount.

The Inherent Limitation: Mechanical Weakness

The primary drawback of pure PTFE is its softness. It is susceptible to "creep" (deformation under sustained load) and has poor resistance to abrasion and wear, which has historically limited its use in high-load mechanical applications.

How Composites Overcome PTFE's Limitations

The development of PTFE composites is a direct response to its mechanical weaknesses. By introducing filler materials into the PTFE matrix, we can dramatically enhance specific properties.

The Principle of Composite Fillers

Fillers are microscopic particles or fibers of other materials, such as glass, carbon, bronze, or graphite. Each filler is chosen to impart a specific benefit, turning PTFE from a specialized sealing material into a versatile engineering plastic.

Enhancing Wear Resistance and Strength

This is the most significant impact. Adding fillers like carbon or bronze dramatically increases the material's hardness and ability to resist wear. A bronze-filled PTFE composite can handle mechanical loads and abrasive conditions that would destroy pure PTFE in short order.

Improving Dimensional Stability

Fillers reduce PTFE's tendency to deform under load and change shape with temperature fluctuations. This improved dimensional stability is critical for components that must maintain tight tolerances to function correctly, such as high-performance seals and bearings.

The Role of Advanced Machining

An advanced material is only as good as our ability to shape it. Modern machining techniques are what unlock the full potential of these new PTFE composites.

Precision Unlocks Performance

Complex applications in aerospace, medical devices, and semiconductor manufacturing demand components with intricate features and extremely tight tolerances. Advanced CNC (Computer Numerical Control) machining provides this required level of precision.

CNC Milling for Complex Geometries

CNC milling uses rotating cutters to remove material and is essential for creating parts with complex shapes, cavities, and non-symmetrical features. This allows for the design of highly optimized and integrated components.

CNC Turning for Rotational Parts

For cylindrical parts like shafts, rings, insulators, and seals, CNC turning is the primary method. It enables the creation of perfectly concentric parts with precise diameters and smooth surface finishes, which is critical for effective sealing and low-friction movement.

Drilling and Tapping for Integration

The ability to precisely drill holes and cut internal threads (tapping) is fundamental for assembling components. Controlled machining ensures that these features are created without damaging the material's integrity, guaranteeing secure and reliable connections.

Understanding the Trade-offs

While composites offer significant advantages, their selection and use require a clear understanding of the compromises involved.

No Single "Super Material"

Every filler adds a benefit at a cost. For example, adding glass fibers increases hardness and wear resistance but can make the composite more abrasive to mating surfaces. It's a targeted engineering choice, not a universal upgrade.

Potential Compromise on Core Properties

While composites improve mechanical characteristics, they can sometimes slightly reduce PTFE's other elite properties. A filled composite may have marginally less chemical resistance or lower dielectric strength than its pure, virgin counterpart.

Increased Machining Complexity

Filled PTFE composites can be more challenging to machine than pure PTFE. The abrasive nature of fillers like glass or carbon can cause faster tool wear, requiring specialized tooling and expertise to maintain precision and achieve a quality surface finish.

Making the Right Choice for Your Application

The convergence of new materials and manufacturing techniques provides more options than ever before. Your final decision must be guided by the primary demand of your application.

- If your primary focus is maximum chemical purity and inertness: Virgin, unfilled PTFE remains the superior choice for applications in food processing, pharmaceuticals, or high-purity chemical handling.

- If your primary focus is mechanical performance under load: A filled composite, such as carbon or bronze-filled PTFE, is necessary to provide the required wear resistance and dimensional stability for bearings or structural components.

- If your primary focus is a complex part with tight tolerances: Your success depends on advanced CNC machining capabilities to transform the raw material into a functional, reliable component.

Ultimately, the synergy between advanced materials and precision manufacturing is what turns a theoretical possibility into a reliable industrial solution.

Summary Table:

| Material / Technique | Primary Benefit | Key Application |

|---|---|---|

| Pure PTFE | Unmatched chemical inertness, low friction | Chemical processing, seals, non-stick surfaces |

| Glass/Carbon-Filled PTFE | Enhanced wear resistance, strength | High-load bearings, mechanical components |

| Bronze/Graphite-Filled PTFE | Improved dimensional stability, load capacity | Seals, bearings, structural parts |

| Advanced CNC Machining | Precision for complex geometries, tight tolerances | Aerospace, medical devices, semiconductor parts |

Ready to engineer a solution tailored to your application's demands?

At KINTEK, we specialize in manufacturing precision PTFE components—from seals and liners to custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in both material selection (including advanced composites) and high-precision CNC machining ensures your parts meet exact performance requirements, whether for prototypes or high-volume orders.

Contact us today to discuss how our PTFE solutions can enhance your project's durability, precision, and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials