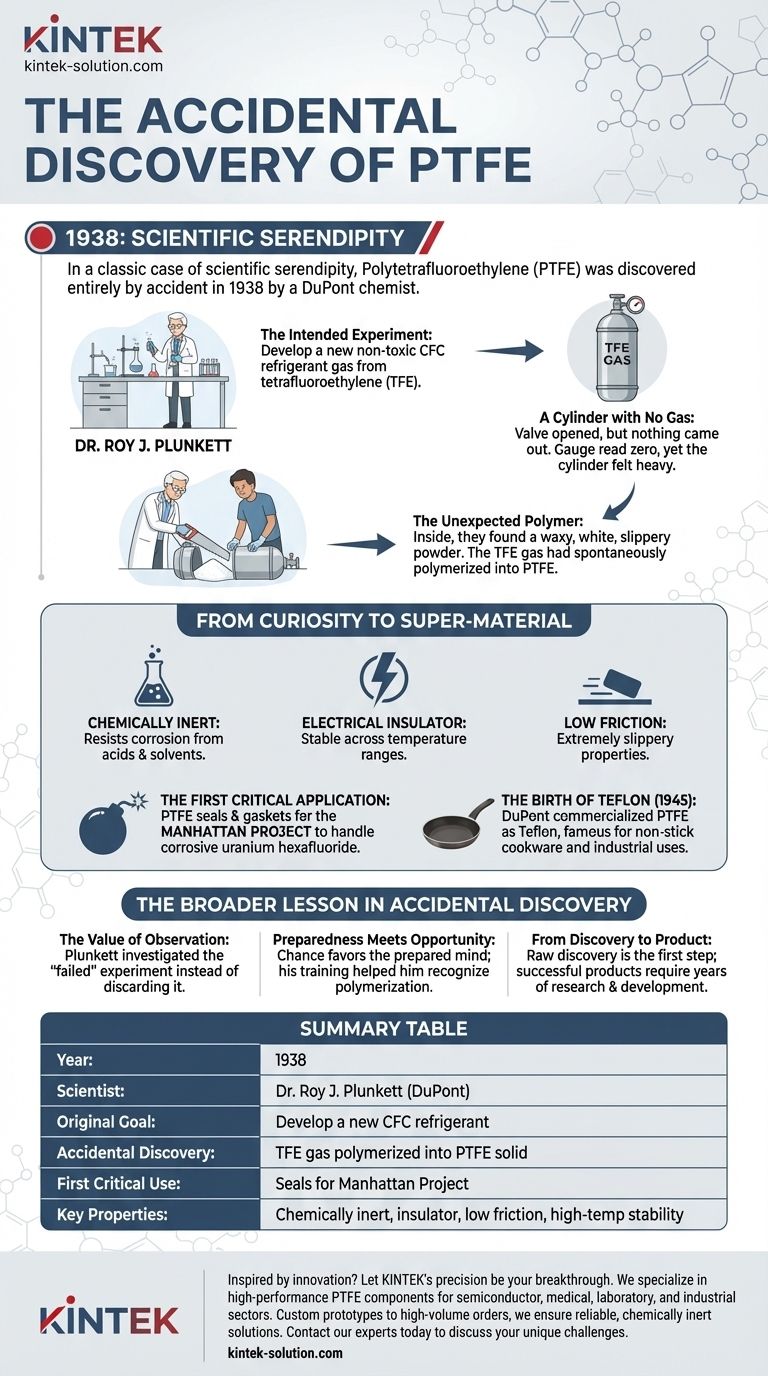

In a classic case of scientific serendipity, Polytetrafluoroethylene (PTFE) was discovered entirely by accident in 1938. A chemist working for DuPont was attempting to develop a new type of refrigerant gas, but instead found that his source material had unexpectedly transformed into a mysterious, waxy white solid with incredibly slippery properties.

The discovery of PTFE was not the result of a planned search for a super-material, but a fortunate accident. It serves as a powerful testament to a core principle of innovation: the greatest breakthroughs often come from investigating unexpected failures with curiosity.

The Accidental Breakthrough

The story begins with Dr. Roy J. Plunkett, a chemist at DuPont's Jackson Laboratory in New Jersey. His work was not focused on polymers or coatings, but on finding a new, non-toxic chlorofluorocarbon (CFC) refrigerant.

The Intended Experiment

Plunkett was working with a gas called tetrafluoroethylene (TFE). His plan was to react this gas with hydrochloric acid to create the new refrigerant compound he was after.

To begin the experiment, Plunkett and his assistant retrieved a pressurized cylinder of TFE gas they had prepared earlier.

A Cylinder with No Gas

When they opened the valve on the cylinder, nothing came out. The pressure gauge read zero, suggesting the container was empty.

However, the cylinder still felt heavy, indicating that the TFE—weighing about one kilogram—was somehow still inside. This anomaly was the critical turning point.

The Unexpected Polymer

Instead of discarding the seemingly faulty cylinder, Plunkett's curiosity took over. He and his assistant decided to saw the metal container open to investigate the mystery.

Inside, they didn't find a gas. They found a waxy, white powder that was remarkably slippery. The TFE gas molecules, under pressure, had spontaneously linked together to form a long-chain polymer: polytetrafluoroethylene.

From Curiosity to Super-Material

Plunkett immediately recognized that he had created something new, but its value was not yet clear. The initial investigation into the powder's properties revealed its extraordinary nature.

Investigating the Properties

The new material was found to be chemically inert, meaning it could resist corrosion from even the most aggressive acids and solvents.

It was also an excellent electrical insulator and was stable across a massive range of temperatures. Most famously, it had an extremely low coefficient of friction, making it one of the slipperiest substances known to science.

The First Critical Application

PTFE's unique ability to resist corrosion made it indispensable to the Manhattan Project during World War II.

Scientists needed to handle highly reactive uranium hexafluoride gas, which would destroy nearly any container it touched. Gaskets and seals coated with PTFE were the only materials that could withstand the corrosive compound, making it a vital component in the development of the atomic bomb.

The Birth of Teflon

After the war, DuPont commercialized PTFE under the brand name Teflon in 1945. While its industrial applications in seals, gaskets, and chemical-resistant linings were significant, it became a household name for its use as a non-stick coating on cookware.

The Broader Lesson in Accidental Discovery

The story of PTFE is more than just a historical footnote; it highlights fundamental truths about the nature of scientific and technical progress.

The Value of Observation

The discovery hinged entirely on Plunkett's decision to investigate a "failed" experiment. Had he simply discarded the cylinder, one of the most useful materials of the 20th century might have remained unknown for years.

Preparedness Meets Opportunity

The famous quote, "Chance favors the prepared mind," applies perfectly here. Plunkett's training as a chemist allowed him to recognize that polymerization was the likely cause and that the resulting substance was unusual and worthy of further study.

From Discovery to Product

It is also crucial to note that while the discovery was an accident, turning PTFE into a viable product was not. It required years of intentional, focused research and development by DuPont to understand, produce, and market the material effectively.

Applying the Principles of Discovery

The origin of PTFE offers timeless lessons for any professional working in a technical, scientific, or creative field.

- If your primary focus is innovation: Embrace anomalies and unexpected results, as they often signal a path to a true breakthrough.

- If your primary focus is research and development: Cultivate a culture of curiosity where "failed" experiments are treated as valuable learning opportunities, not just setbacks.

- If your primary focus is product strategy: Recognize that a raw discovery is just the first step; turning it into a successful product requires a long-term vision and dedicated resources.

Ultimately, the discovery of PTFE is a powerful reminder that progress often happens not when we find the answers we seek, but when we have the wisdom to investigate the questions we never thought to ask.

Summary Table:

| Event | Key Detail |

|---|---|

| Year | 1938 |

| Scientist | Dr. Roy J. Plunkett (DuPont) |

| Original Goal | Develop a new CFC refrigerant gas |

| Accidental Discovery | TFE gas polymerized into a white, waxy solid (PTFE) |

| First Critical Use | Seals and gaskets for the Manhattan Project |

| Key Properties | Chemically inert, excellent insulator, extremely low friction, high-temperature stability |

Inspired by the story of innovation? Let KINTEK's precision be your breakthrough.

The discovery of PTFE shows that the right material can revolutionize an industry. At KINTEK, we specialize in manufacturing high-performance PTFE components—including custom seals, liners, and labware—that meet the demanding requirements of the semiconductor, medical, laboratory, and industrial sectors.

Whether you need a custom prototype or a high-volume order, our commitment to precision production ensures you get the reliable, chemically inert components your applications demand.

Contact our experts today to discuss how our PTFE solutions can solve your unique challenges.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How was PTFE discovered and developed? From Lab Accident to Essential High-Performance Polymer

- What is PTFE commonly known as and what type of material is it? A Guide to High-Performance PTFE Properties

- What are the similarities between PTFE and RPTFE? Unlocking the Core Fluoropolymer Identity

- What environmental resistances does PTFE offer? Unmatched Durability for Harsh Conditions

- What are the additional properties of PTFE? Beyond Non-Stick: Extreme Chemical, Thermal & Electrical Performance