The single most important rule of PTFE-lined bearing maintenance is to never apply traditional lubricants like grease or oil. These bearings are specifically designed to be self-lubricating, and external additives will interfere with their function, attract contaminants, and ultimately lead to premature failure. True maintenance for these components is about protection, not application.

The core principle is that PTFE-lined bearings are engineered to be maintenance-free. Therefore, your maintenance strategy shifts from active lubrication to preventative protection—safeguarding the bearing's self-lubricating surface from contamination and chemical damage.

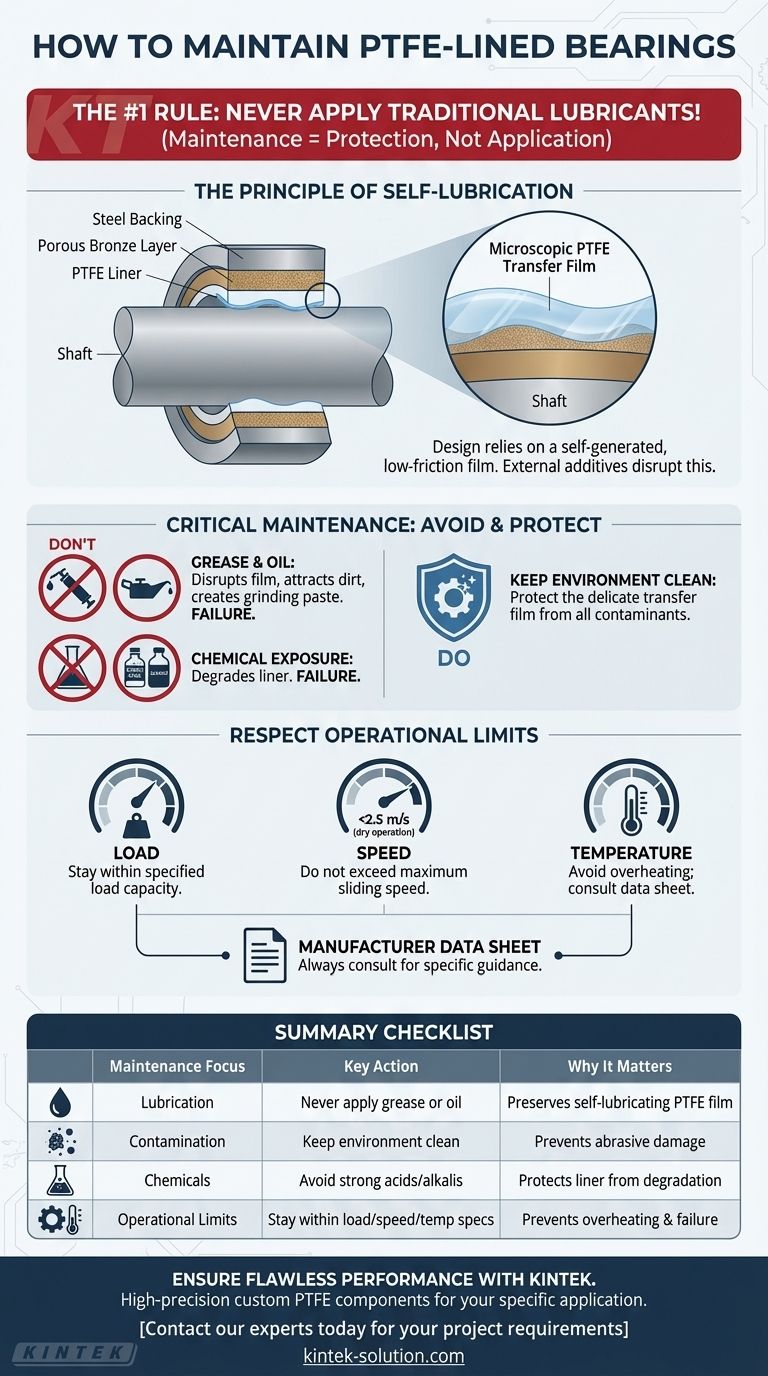

The Principle of Self-Lubrication

To properly maintain these bearings, you must first understand how they function without traditional lubrication. Their design is a multi-layered system working in concert.

How a PTFE Liner Works

A PTFE-lined bearing is not a simple plastic sleeve. It is a composite structure, typically consisting of a steel backing for high load capacity and a layer of sintered bronze.

The key is the liner itself, a mixture of PTFE (polytetrafluoroethylene) and other polymer fibers. This mixture is bonded to the porous bronze layer.

The Critical Transfer Film

During the initial run-in period, a microscopic amount of the PTFE mixture transfers from the bearing liner to the mating surface (the shaft or pin).

This creates an incredibly low-friction lubricant film on both surfaces. The bearing is now essentially sliding against its own material, which is what provides the self-lubricating property.

Inherent Performance Characteristics

This design results in a very low coefficient of friction, often between 0.02 and 0.20 in dry conditions. It also allows for significant load capacities, with static limits reaching up to 250 N/mm² in some cases.

Critical Maintenance: Contamination and Chemical Avoidance

Because these bearings rely on a clean, microscopic transfer film, the primary maintenance task is protecting that surface.

Why External Lubricants are Harmful

Applying grease or oil disrupts the delicate transfer film. These viscous fluids can prevent the PTFE from properly coating the mating surface.

Worse, they act as a magnet for dust, dirt, and other abrasive particles. This mixture creates a grinding paste that will rapidly destroy both the bearing liner and the shaft.

Chemical Incompatibility

While PTFE is resistant to most organic compounds and solvents, it is vulnerable to certain aggressive chemicals.

You must avoid all contact with strong acids, such as nitric and sulfuric acid, as well as strong alkaline fluids. Exposure to these chemicals will degrade the polymer liner and lead to bearing failure.

Understanding the Trade-offs

While offering maintenance-free operation, these bearings are not universally applicable. Their effectiveness depends on staying within specific operational boundaries.

Respecting Operational Limits

Every PTFE-lined bearing has defined limits for load, speed, and temperature. The references note maximum sliding speeds of up to 2.5 m/s in dry operation.

Exceeding these manufacturer-specified limits can overwhelm the self-lubricating film, causing a rapid increase in friction and temperature that leads to failure.

Following Manufacturer Instructions

The composition of the PTFE liner can vary between manufacturers, affecting chemical compatibility and performance limits.

The manufacturer's data sheet is the definitive source of truth. Always consult it for specific guidance on installation, operational limits, and chemical compatibility for your exact bearing.

How to Apply This to Your Project

Your goal is not to perform maintenance but to create an environment where the bearing can perform its maintenance-free function flawlessly.

- If your primary focus is longevity: Prioritize keeping the operating environment immaculately clean and ensure no prohibited lubricants or chemicals can come into contact with the bearing.

- If your primary focus is high performance: Verify that your application's load, speed, and temperature requirements fall well within the manufacturer's specified limits for the bearing.

- If you are replacing a traditional bearing: Erase old habits. Your new procedure is to protect the bearing from all external lubrication and contamination, not to schedule it.

Properly understanding and protecting these components allows you to leverage their full, maintenance-free potential.

Summary Table:

| Maintenance Focus | Key Action | Why It Matters |

|---|---|---|

| Lubrication | Never apply grease or oil | Preserves the self-lubricating PTFE transfer film |

| Contamination | Keep the operating environment clean | Prevents abrasive particles from damaging the liner and shaft |

| Chemical Exposure | Avoid strong acids and alkalis | Protects the PTFE liner from chemical degradation |

| Operational Limits | Stay within load, speed, and temperature specs | Prevents overheating and failure of the lubricating film |

Ensure your PTFE components perform flawlessly.

At KINTEK, we specialize in manufacturing high-precision, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your bearings and other critical parts are built for maximum, maintenance-free performance in your specific application.

Let us help you optimize your equipment. Contact our experts today to discuss your project requirements, from prototypes to high-volume production.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers