In material science, virgin grade Polytetrafluoroethylene (PTFE) is considered one of the purest engineering polymers available. Its exceptional purity is not defined by a percentage, but by its composition: it is made exclusively from new PTFE resin, containing no fillers, additives, or recycled content. This makes it the benchmark for applications where any form of contamination is unacceptable.

The term "purity" in the context of virgin PTFE refers directly to the absence of additives. This singular focus on pure polymer gives it unmatched chemical inertness, making it indispensable for highly sensitive industries like semiconductor manufacturing and analytical science.

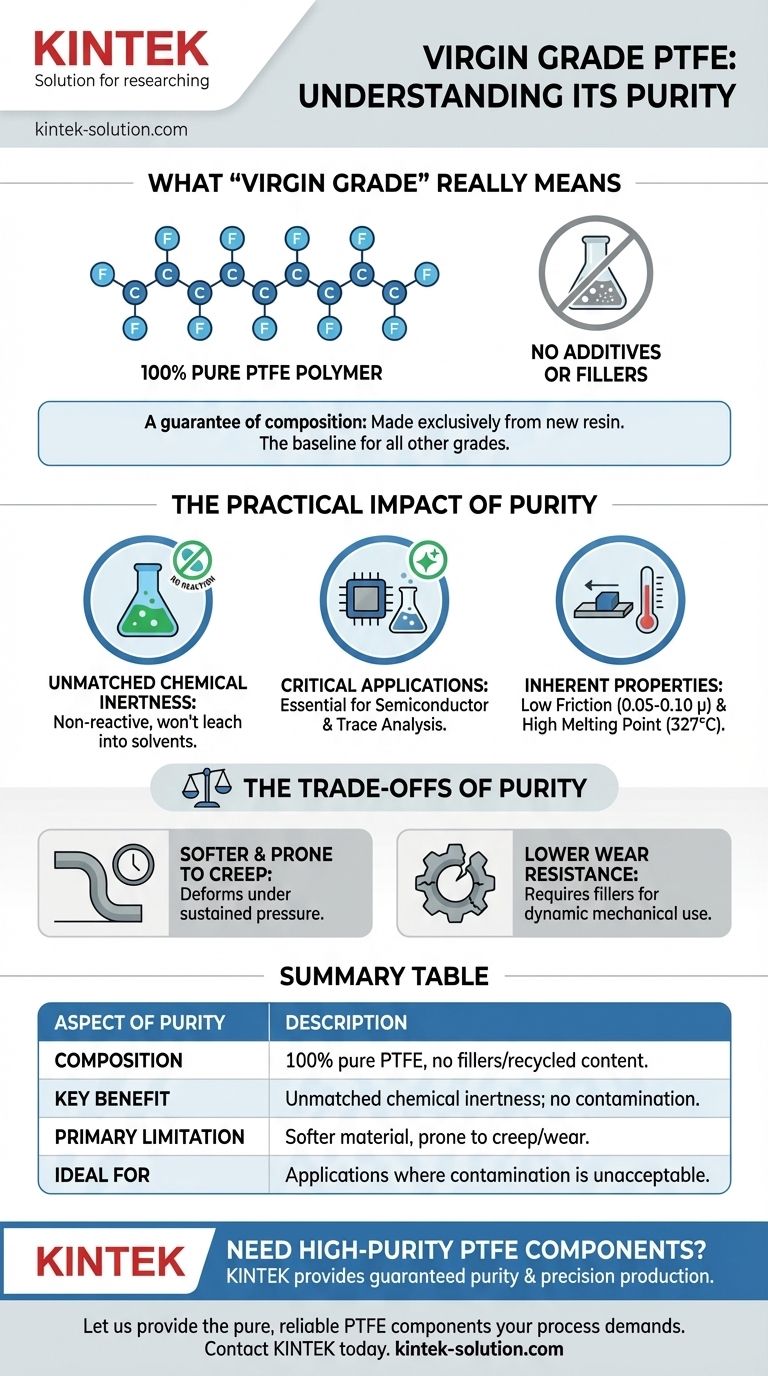

What "Virgin Grade" Purity Really Means

The concept of purity for virgin PTFE is fundamentally about what has been excluded from the material during its production. It is a guarantee of composition.

The Absence of Additives

The primary definition of virgin grade is that it is 100% pure PTFE polymer. No fillers like glass, carbon, or bronze have been added to alter its properties. It also contains no pigments or reprocessed materials.

A Chemically Simple Structure

At a molecular level, PTFE is a fluoropolymer composed of only carbon and fluorine atoms. This incredibly strong carbon-fluorine bond is responsible for its remarkable properties, including its resistance to almost all chemicals.

The Baseline for All Other Grades

Virgin PTFE represents the baseline material from which all other "filled" or "mechanical" grades are derived. Those other grades intentionally sacrifice purity by adding materials to enhance specific mechanical traits like wear resistance or compressive strength.

The Practical Impact of Purity

The absolute purity of virgin PTFE is not just a technical detail; it is the direct source of its most valued characteristics.

Unmatched Chemical Inertness

Because it contains no reactive additives, virgin PTFE is one of the most chemically inert substances known. It will not react with or leach contaminants into virtually any solvent, acid, or base it contacts.

Suitability for Critical Applications

This non-leaching property makes it essential for high-purity applications. In semiconductor manufacturing, any microscopic impurity can ruin a wafer. In trace analysis for scientific research, the labware itself cannot be a source of contamination.

Inherent Physical Properties

The properties of virgin PTFE—such as its extremely low coefficient of friction (0.05-0.10) and high melting point (327°C / 621°F)—are inherent to the pure polymer. They are not achieved through additives but are a direct result of its molecular structure.

Understanding the Trade-offs of Purity

While its purity is a significant advantage, it also results in specific limitations. No material is perfect for every application.

Softer and Prone to Creep

Compared to filled grades, virgin PTFE is a relatively soft material. Under sustained pressure, it can be susceptible to "creep" or cold flow, meaning it can deform over time.

Lower Wear Resistance

For dynamic mechanical applications like bearings or seals, virgin PTFE has lower wear resistance. Fillers like bronze or carbon are specifically added to other PTFE grades to drastically improve their durability and lifespan in these scenarios.

When Purity Is Not the Goal

If your application requires high mechanical strength, thermal conductivity, or abrasion resistance, a "less pure" filled grade of PTFE is often the superior engineering choice. The additives in these grades are a functional enhancement, not an impurity.

Making the Right Choice for Your Application

Selecting the correct grade of PTFE requires understanding whether purity or mechanical performance is your primary driver.

- If your primary focus is non-contamination and chemical resistance: Virgin grade PTFE is the only choice, as its purity ensures it will not react with or leach into your process fluids or samples.

- If your primary focus is mechanical strength or wear resistance: You should consider a filled or mechanical grade of PTFE, where additives are intentionally used to enhance properties like hardness and durability.

Ultimately, understanding that virgin PTFE's purity is both its greatest strength and its primary limitation is the key to selecting the correct material for your needs.

Summary Table:

| Aspect of Purity | Description |

|---|---|

| Composition | 100% pure PTFE polymer with no fillers, pigments, or recycled content. |

| Key Benefit | Unmatched chemical inertness; will not leach contaminants. |

| Primary Limitation | Softer material, prone to creep and has lower wear resistance than filled grades. |

| Ideal For | Applications where contamination is unacceptable (e.g., semiconductor manufacturing, analytical science). |

Need High-Purity PTFE Components?

For applications where absolute purity is non-negotiable, KINTEK's precision-manufactured virgin PTFE components are the trusted solution. We serve the semiconductor, medical, and laboratory industries with custom-fabricated seals, liners, and labware that guarantee zero contamination.

Our value to you:

- Guaranteed Purity: Components made from 100% virgin PTFE resin.

- Precision Production: Expert manufacturing from prototypes to high-volume orders.

- Industry Expertise: Deep understanding of the stringent requirements for sensitive applications.

Let us provide the pure, reliable PTFE components your process demands.

Contact KINTEK today to discuss your project requirements

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments