In the medical sector, Teflon is used extensively for implants, catheters, surgical tools, and sterile equipment. Its value comes from a unique combination of being chemically inert, having an extremely low-friction surface, and resisting bacterial contamination, making it one of the most versatile and reliable materials in modern healthcare.

The core reason Teflon is indispensable in medicine is its biocompatibility. It does not react with bodily fluids or tissues, ensuring patient safety for everything from permanent implants to temporary medical devices.

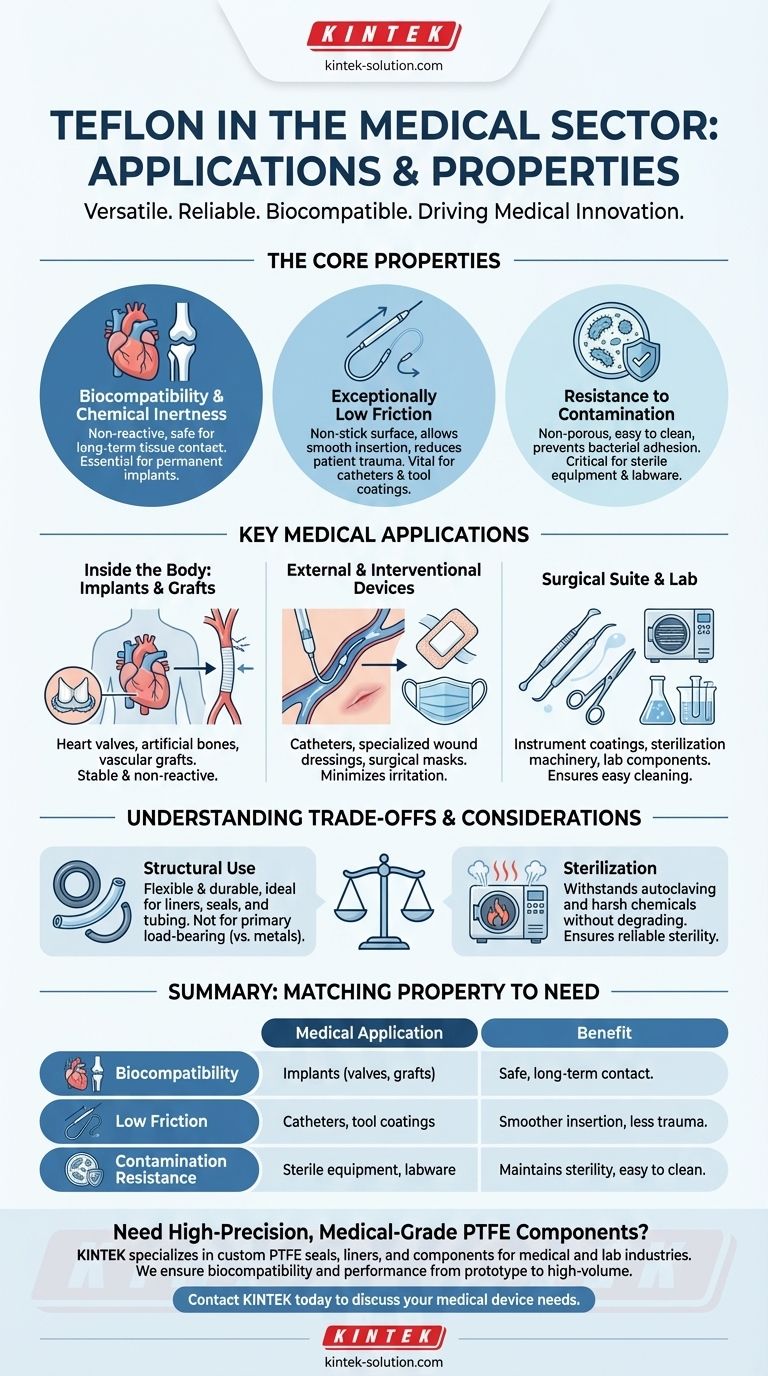

The Core Properties Driving Medical Innovation

The widespread adoption of Teflon, or Polytetrafluoroethylene (PTFE), in medicine is not accidental. It is a direct result of three fundamental material properties that solve critical challenges in patient care and device manufacturing.

Biocompatibility and Chemical Inertness

Teflon is exceptionally non-reactive. This chemical inertness means it can be placed inside the human body without triggering an immune response or chemical degradation.

This makes it a premier material for creating artificial body parts that must coexist with living tissue for long periods, such as heart valves, artificial bones, dentures, and durable sutures.

Exceptionally Low Friction

Teflon is famous for its non-stick, low-friction surface. This "slippery" quality is critical for devices that must pass through or interact with sensitive bodily tissues.

This property is leveraged in catheters and guide wires, allowing for smoother and less traumatic insertion. It is also used as a coating on surgical instruments to prevent tissue from sticking during procedures.

Resistance to Contamination

The surface of Teflon is not only low-friction but also highly resistant to contamination and easy to clean. Its non-porous nature makes it difficult for bacteria to adhere and colonize.

This characteristic is vital for maintaining sterility in surgical and laboratory environments. It is used in sterilization equipment, lab instruments, and even wound dressings to create a sterile barrier.

A Survey of Key Medical Applications

Teflon's unique properties translate into a wide array of practical uses across different medical domains, from invasive surgery to everyday patient care.

Inside the Body: Implants and Grafts

Because it is not rejected by the body, Teflon is used to manufacture a variety of long-term implants. These include components for heart valves, artificial bones, and vascular grafts that require a stable, non-reactive material.

External and Interventional Devices

For devices that interact with the body, Teflon's low friction and sterile surface are paramount. It is a key material for catheters, which must be inserted with minimal irritation.

It is also found in specialized wound dressings, where its non-stick quality prevents damage to healing tissue upon removal, and in surgical masks for its flame-retardant properties.

In the Surgical Suite and Lab

The need for absolute sterility makes Teflon invaluable for reusable equipment. Coatings on surgical instruments ensure they are easy to clean and sterilize effectively.

Furthermore, its resistance to harsh chemicals and contamination makes it a standard material for lab equipment and components in pharmaceutical packaging and sterilization machinery.

Understanding the Trade-offs and Considerations

While Teflon's properties make it highly valuable, its application must be chosen carefully based on engineering and medical requirements. No single material is perfect for every situation.

Material Properties and Structural Use

Teflon is a durable and malleable polymer, but it is not as rigid or strong as medical-grade metals like titanium. It is ideal for components where flexibility and inertness are the primary needs, such as liners, seals, or flexible tubing.

For high-stress, load-bearing applications like a primary joint replacement, it is often used as a component within a larger assembly of stronger materials, not as the sole structural element.

Sterilization and Processing

A key consideration for any medical material is its ability to withstand common sterilization methods like autoclaving. Teflon's thermal and chemical stability allow it to endure these processes without degrading.

This ensures that devices and instruments made from or coated with Teflon can be reliably made sterile for safe patient use, a critical factor in its widespread adoption.

Making the Right Choice for Your Goal

Selecting a material in the medical field is about matching its inherent properties to a specific clinical need. Teflon offers a powerful and reliable solution for a distinct set of challenges.

- If your primary focus is biocompatible implants: Teflon's chemical inertness makes it a premier choice for parts that must not react with the body, like grafts or valve components.

- If your primary focus is low-friction medical devices: Its non-stick surface is ideal for catheters and coating surgical tools to improve performance and minimize patient trauma.

- If your primary focus is maintaining a sterile environment: The easy-to-clean, contamination-resistant nature of Teflon is invaluable for lab equipment and reusable instruments.

Ultimately, Teflon's role in medicine is a testament to how a material's fundamental chemistry can be leveraged to solve complex human health problems safely and effectively.

Summary Table:

| Key Property | Medical Application | Benefit |

|---|---|---|

| Biocompatibility | Implants (heart valves, grafts) | Safe, long-term contact with tissues/fluids |

| Low Friction | Catheters, surgical instrument coatings | Smoother insertion, less patient trauma |

| Contamination Resistance | Sterile equipment, labware | Easy to clean, maintains sterility |

Need High-Precision, Medical-Grade PTFE Components?

KINTEK specializes in manufacturing custom PTFE seals, liners, labware, and components for the medical, semiconductor, and laboratory industries. Our commitment to precision production ensures your devices meet the highest standards for biocompatibility and performance, from prototype to high-volume orders.

Contact KINTEK today to discuss how our PTFE solutions can enhance your medical device's safety and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications