In the medical and pharmaceutical fields, Polytetrafluoroethylene (PTFE) is utilized in a wide range of critical applications due to its unique combination of properties. It is found in components from surgical implants and catheters to high-purity seals and tubing in drug manufacturing equipment. Its value stems from its exceptional chemical resistance, biocompatibility, and durability in sterile environments.

The core reason PTFE is indispensable in medicine and pharmaceuticals is its profound inertness. It does not react with biological tissue, aggressive chemicals, or sterilization processes, which is the absolute standard for ensuring patient safety and product purity.

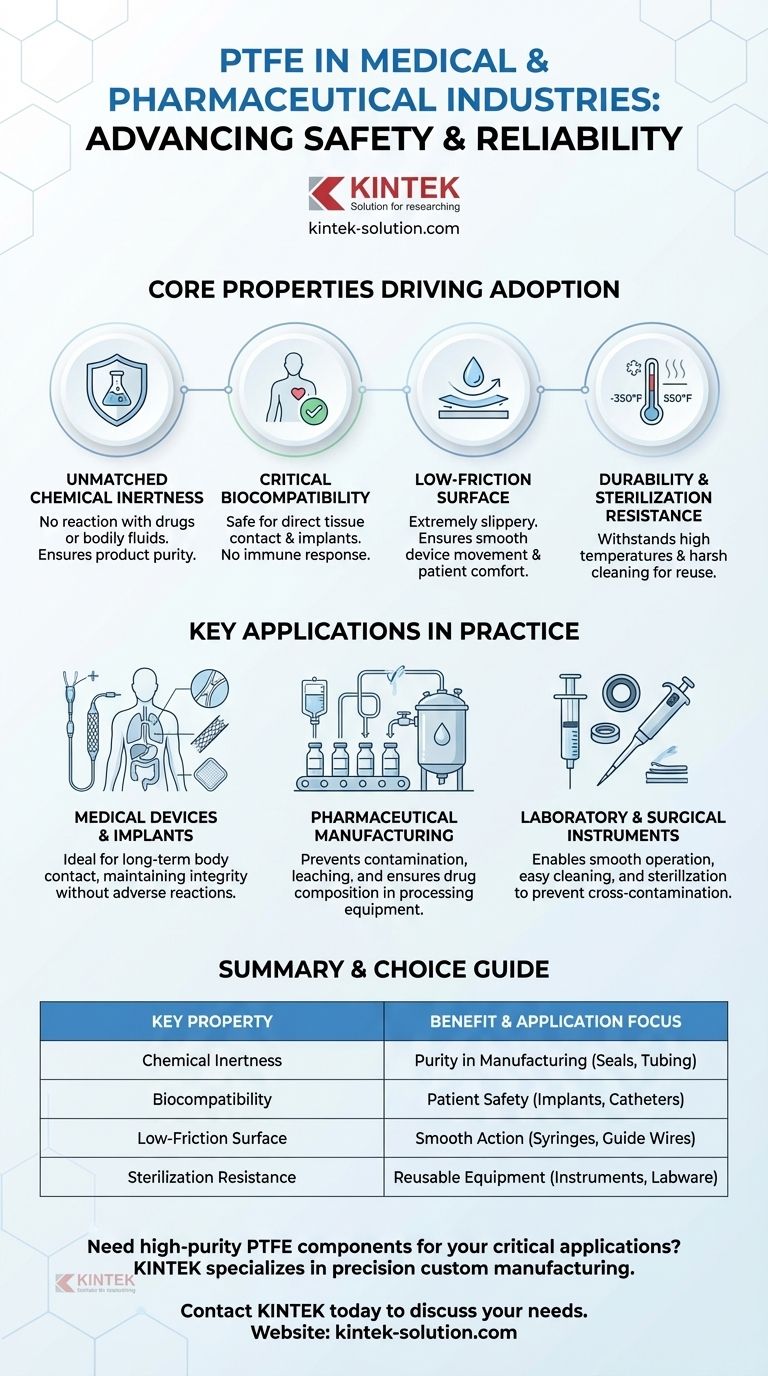

The Core Properties Driving Adoption

To understand PTFE's role, we must first examine the fundamental material characteristics that make it so uniquely suited for these demanding industries. These properties work in concert to meet stringent regulatory and performance standards.

Unmatched Chemical Inertness

PTFE’s most valued characteristic is its extreme chemical inertness. This means it does not react with bodily fluids, aggressive drugs, or harsh sterilization agents.

This property is paramount for maintaining the purity and safety of pharmaceutical products and ensuring medical devices perform predictably without degrading.

Critical Biocompatibility

Biocompatibility means a material does not produce a toxic or immunological response when exposed to the body. PTFE is highly biocompatible, making it a trusted material for implants and devices that come into direct contact with human tissue.

This allows for its use in applications like sutures, synthetic blood vessels, and surgical membranes for procedures like glaucoma surgery.

Low-Friction Surface

PTFE has one of the lowest coefficients of friction of any solid, giving it a uniquely slippery, non-stick surface.

In medical instruments like syringe plungers, catheters, and guide wires, this ensures smooth, frictionless movement, enhancing precision and minimizing patient discomfort.

Durability and Sterilization Resistance

PTFE is exceptionally durable and can withstand a wide temperature range, from -350°F to 550°F.

This thermal stability makes it compatible with common sterilization methods, such as autoclaving, which is essential for reusable medical equipment and manufacturing components. Its hygienic surface also resists bacterial growth and is easy to clean.

Key Applications in Practice

These core properties translate directly into specific, high-stakes applications across both medical treatment and pharmaceutical production.

Medical Devices and Implants

The combination of biocompatibility and inertness makes PTFE ideal for components that reside inside the body. This includes catheters, stent grafts, and surgical patches.

Its durability ensures these components maintain their integrity and function over the long term without causing adverse reactions.

Pharmaceutical Manufacturing

In drug manufacturing, preventing contamination is the highest priority. PTFE is used for tubing, gaskets, and seals in processing equipment that handles corrosive or high-purity chemicals.

Its non-reactive nature ensures that no material leaches into the drug product, preserving its intended chemical composition and efficacy. Liners for pharmaceutical caps are also often made of PTFE to provide a secure, non-contaminating seal.

Laboratory and Surgical Instruments

The low-friction and hygienic properties of PTFE are leveraged in precision instruments. It is used in syringe plungers, pump seals, and sample transport mechanisms.

This ensures that delicate instruments operate smoothly and can be cleaned and sterilized effectively between uses, preventing cross-contamination.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. Its primary limitations are mechanical. Compared to metals or other high-performance polymers, PTFE has lower tensile strength and is susceptible to creep under sustained load.

Furthermore, it cannot be processed using conventional melt-extrusion or injection molding, requiring specialized manufacturing techniques. These factors must be considered during the design phase of any component.

Making the Right Choice for Your Application

Selecting a material for a medical or pharmaceutical application requires aligning its properties with the primary goal of the component.

- If your primary focus is patient contact or implantation: Prioritize PTFE for its superior biocompatibility and proven history of not causing adverse bodily reactions.

- If your primary focus is product purity in manufacturing: Leverage PTFE's chemical inertness to guarantee that no part of your equipment will react with or contaminate the final drug product.

- If your primary focus is smooth mechanical action in a device: Utilize PTFE's extremely low coefficient of friction for components like catheters or plungers to ensure reliable, precise operation.

Ultimately, PTFE's unique profile makes it a foundational material for advancing safety, reliability, and performance in healthcare.

Summary Table:

| Key Property | Benefit in Medical/Pharma | Common Applications |

|---|---|---|

| Chemical Inertness | Prevents reaction with drugs & bodily fluids | Seals, tubing, liners for drug manufacturing equipment |

| Biocompatibility | Safe for implantation and tissue contact | Catheters, stent grafts, surgical patches |

| Low-Friction Surface | Ensures smooth operation of devices | Syringe plungers, guide wires, catheters |

| Sterilization Resistance | Withstands autoclaving and harsh cleaning | Reusable medical instruments, labware |

Need high-purity, biocompatible PTFE components for your medical or pharmaceutical application?

KINTEK specializes in the precision manufacturing of custom PTFE seals, liners, tubing, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our components are engineered to meet the stringent demands for purity, durability, and performance that your industry requires.

We offer custom fabrication from prototypes to high-volume orders, ensuring your critical applications are supported with reliable, contamination-free solutions.

Contact KINTEK today to discuss your specific needs and leverage our expertise in advanced PTFE manufacturing.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials