In the food and beverage industry, Polytetrafluoroethylene (PTFE) is a cornerstone material used for its unique combination of properties. It is most famously applied as a non-stick, heat-resistant coating on cookware, but its role extends deep into industrial settings. In food processing, it is used for sanitary seals, self-lubricating bearings that eliminate the need for contaminating grease, and as liners for equipment to prevent corrosion and product buildup.

The value of PTFE is not just one feature, but its unique combination of being chemically inert, heat-resistant, and having an extremely low-friction (non-stick) surface. This trifecta makes it uniquely suited for applications where both performance and food safety are non-negotiable.

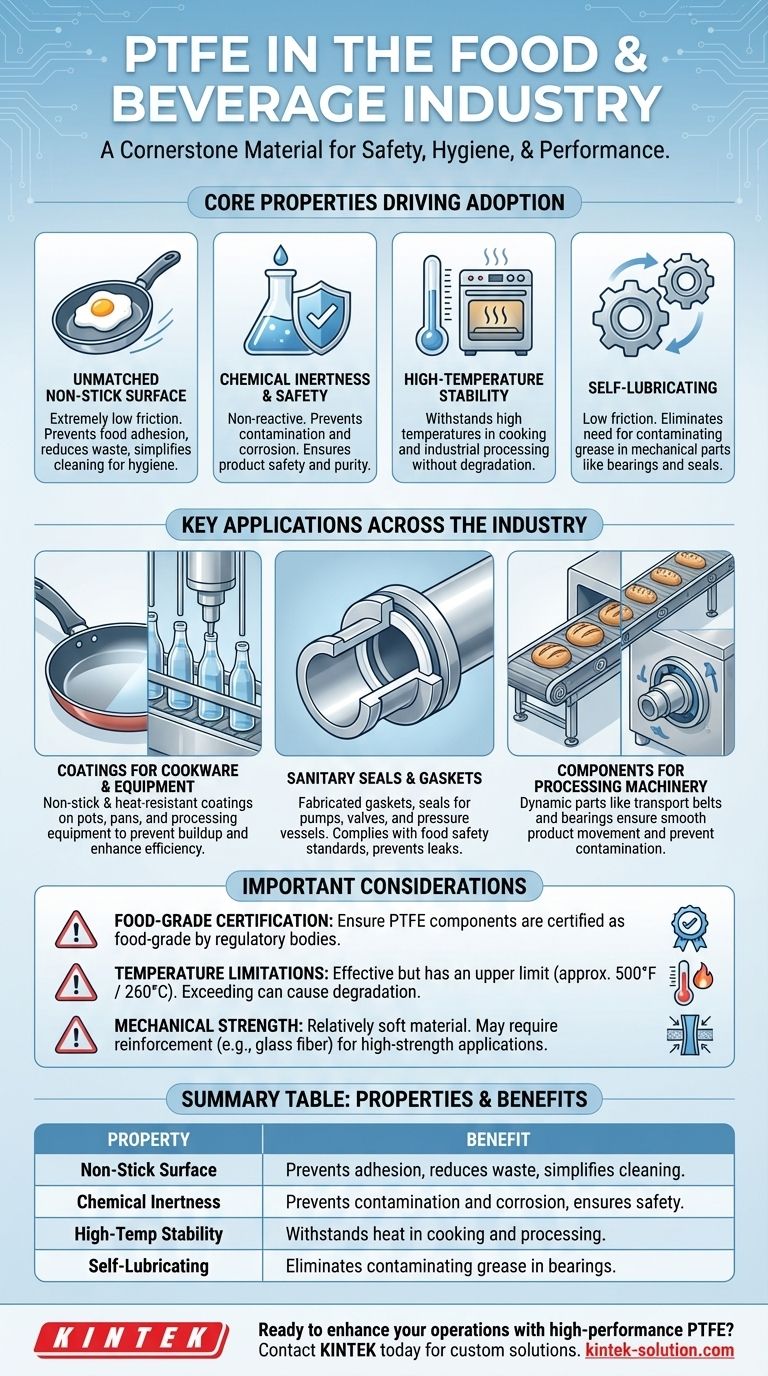

The Core Properties Driving PTFE Adoption

To understand why PTFE is so prevalent, we must look at its fundamental characteristics. These properties directly solve critical challenges in food handling, from consumer kitchens to large-scale manufacturing.

Unmatched Non-Stick Surface

The most recognized quality of PTFE is its extremely low coefficient of friction, making it one of the most non-stick materials known.

This property is critical for preventing food from adhering to surfaces. This ensures easy release on baking sheets and transport belts, reduces product waste, and simplifies cleaning, which is essential for maintaining hygienic conditions.

Chemical Inertness and Food Safety

PTFE is highly non-reactive and does not react with the vast majority of chemicals, including acidic food ingredients or strong cleaning agents.

This chemical inertness is vital for food safety. It prevents any material from leaching into the product, protecting it from contamination. It also protects equipment, such as storage containers and pipes, from corrosion.

High-Temperature Stability

PTFE can withstand consistent use at high temperatures without degrading, making it more durable than many other polymers in cooking and baking applications.

This heat resistance is essential for cookware, oven components, and industrial processing equipment used in baking or confectionery production.

Self-Lubricating for Mechanical Parts

The low-friction nature of PTFE allows it to function as a dry lubricant in mechanical components.

In food processing machinery, this is a significant advantage. PTFE bearings and seals can operate smoothly without traditional grease or oil, which would be a major source of product contamination.

Key Applications Across the Industry

These core properties translate into specific, high-value applications that span the entire food and beverage lifecycle.

Coatings for Cookware and Equipment

The most visible use of PTFE is as a coating on pots and pans. This application leverages both its non-stick and heat-resistant properties.

Industrially, these same coatings are applied to the surfaces of processing and bottling equipment to prevent the buildup of deposits, which can reduce operational efficiency and create hygiene issues.

Sanitary Seals and Gaskets

PTFE is fabricated into gaskets and seals for equipment like pumps, valves, pressure vessels, and heat exchangers.

Its non-stick surface prevents food particles from sticking, which could harbor bacteria. Its non-reactive nature ensures it complies with strict food safety standards, preventing leaks without contaminating the product.

Components for Processing Machinery

Beyond static seals, PTFE is used for dynamic parts. PTFE-coated transport belts are common in bakeries and confectionery plants, ensuring products move smoothly without sticking.

Similarly, it is used in mixers and for rotary shaft seals to create a barrier that prevents external contaminants or lubricants from entering the food product.

Understanding the Trade-offs and Considerations

While highly effective, PTFE is not a universal solution. An objective assessment requires understanding its limitations.

Importance of Food-Grade Certification

Not all PTFE is suitable for food contact. It is critical to ensure that any PTFE component used in a food application is certified as food-grade by regulatory bodies to guarantee its safety and purity.

Temperature Limitations

Although highly heat-resistant, PTFE does have an upper temperature limit. If heated beyond this point (typically around 500°F or 260°C), it can begin to degrade. This is a primary consideration for its safe use in high-temperature cooking and industrial processes.

Mechanical Strength

PTFE is a relatively soft material. In applications requiring high mechanical strength or abrasion resistance, it may need to be reinforced with other materials like glass fiber or stainless steel to provide the necessary durability.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the specific challenge you need to solve.

- If your primary focus is consumer product performance: The non-stick and heat-resistant properties of PTFE coatings for cookware are paramount for user convenience and durability.

- If your primary focus is industrial process hygiene: The chemical inertness and non-stick surface of food-grade PTFE are critical for seals, gaskets, and equipment linings to ensure safety and easy sanitation.

- If your primary focus is mechanical reliability in equipment: The self-lubricating, low-friction nature of PTFE is the key benefit for bearings and dynamic seals, as it eliminates the risk of product contamination from traditional lubricants.

Ultimately, leveraging PTFE correctly means matching its unique combination of properties to the specific demands of safety, efficiency, and reliability in your food or beverage application.

Summary Table:

| Property | Benefit in Food & Beverage Industry |

|---|---|

| Non-Stick Surface | Prevents food adhesion, reduces waste, and simplifies cleaning for hygiene. |

| Chemical Inertness | Prevents contamination and corrosion, ensuring product safety and purity. |

| High-Temperature Stability | Withstands heat in cooking and industrial processing without degrading. |

| Self-Lubricating | Eliminates need for contaminating grease in bearings and seals. |

Ready to enhance your food and beverage operations with high-performance PTFE components?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, labware, and custom parts—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment meets the highest standards of food safety and operational efficiency.

We offer custom fabrication from prototypes to high-volume orders, tailored to your specific needs. Contact KINTEB today to discuss your project and discover the right PTFE solution for you.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F